- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

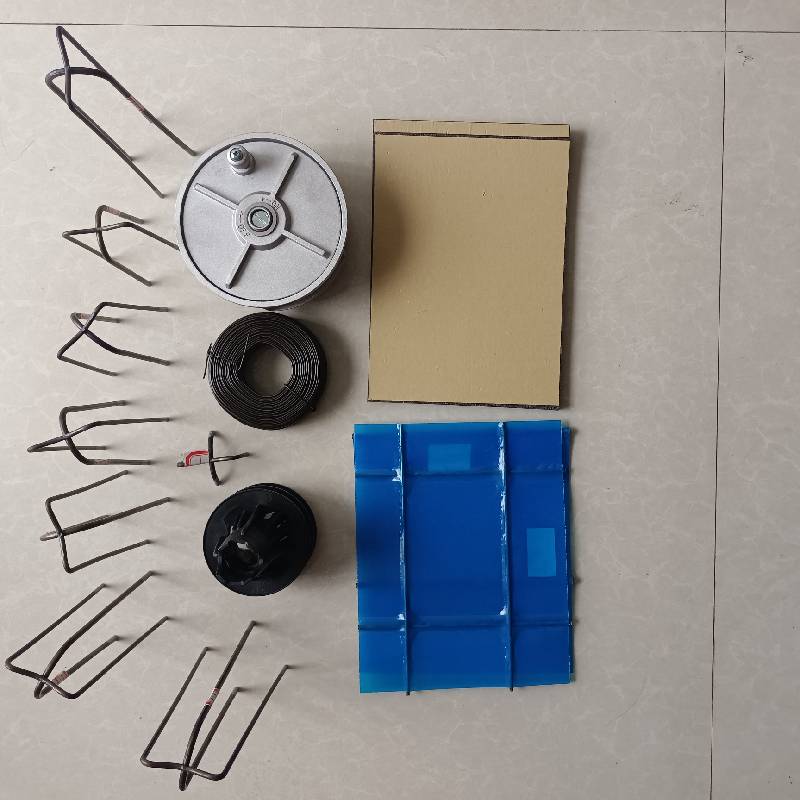

compression spring 20mm

Understanding Compression Springs The 20mm Variant

When it comes to mechanical engineering and design, the importance of springs cannot be overstated. Among the various types of springs, compression springs hold a prominent position, revered for their versatility and efficiency in storing potential energy. In this article, we will delve into the nuances of compression springs, focusing specifically on the 20mm variant, exploring its applications, designs, and the factors affecting its performance.

What Is a Compression Spring?

A compression spring is a type of spring that resists compressive forces, meaning it is designed to be compressed under load. When force is applied to the ends of the spring, it shortens in length while storing energy. Once the force is removed, the spring returns to its original shape and length, releasing the stored energy. This characteristic makes compression springs essential components in a wide array of applications, from automotive to consumer electronics.

The 20mm Compression Spring Specifications

The term 20mm compression spring typically refers to the wire diameter, coil diameter, or the total height of the spring when not loaded. Depending on the specific design, a 20mm compression spring can come with various wire diameters, coil counts, and materials, affecting its stiffness and load-bearing capacities.

- Wire Diameter The thickness of the wire used in a spring significantly impacts its strength and flexibility. A thicker wire can withstand higher loads but may reduce the spring's overall compression ability. - Coil Diameter The coil diameter of a 20mm compression spring can vary, influencing how much weight it can support and how much it will compress under a given load. - Free Length This dimension, when the spring is not under any external load, can also vary, affecting the amount of compression possible.

Key Applications of 20mm Compression Springs

Compression springs are ubiquitous across multiple industries

. Some common applications for a 20mm compression spring includecompression spring 20mm

1. Automotive Industry They are frequently employed in suspensions, engine compartments, and numerous other components to enhance a vehicle's performance and comfort. 2. Consumer Electronics In devices like keyboards and remote controls, they provide the necessary tactile feedback that users often expect. 3. Industrial Machinery Compression springs play a critical role in the operation of various machinery, ranging from simple fixtures to complex automation systems. 4. Medical Devices These springs are essential in medical equipment, where precise control and reliability are paramount.

Factors Influencing Performance

The performance of compression springs, including those of 20mm diameter, is influenced by several factors

- Material Composition Common materials for compression springs include stainless steel, music wire, and various alloy steels. Each material offers distinct advantages in strength, corrosion resistance, and fatigue life.

- Thermal Treatment Often, compression springs undergo heat treatment processes to enhance their mechanical properties, allowing for higher performance under load.

- Coating and Finishing Springs can be coated or treated with anti-corrosive substances to extend their lifespan, especially in environments prone to moisture and corrosion.

Conclusion

The 20mm compression spring exemplifies the intricate balance of design, material science, and application. As industries continue to evolve, the demand for efficient and reliable spring solutions remains constant. Understanding the specifications, applications, and influencing factors behind these components is vital for engineers and designers. As technology advances, we can expect further innovations in spring design, contributing to the overall improvement of machinery and devices in which they play a critical role. Recognizing the significance of compression springs, particularly the 20mm variety, allows engineers to harness their potential effectively, ensuring performance and reliability in countless applications.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025