- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

1月 . 14, 2025 12:34

Back to list

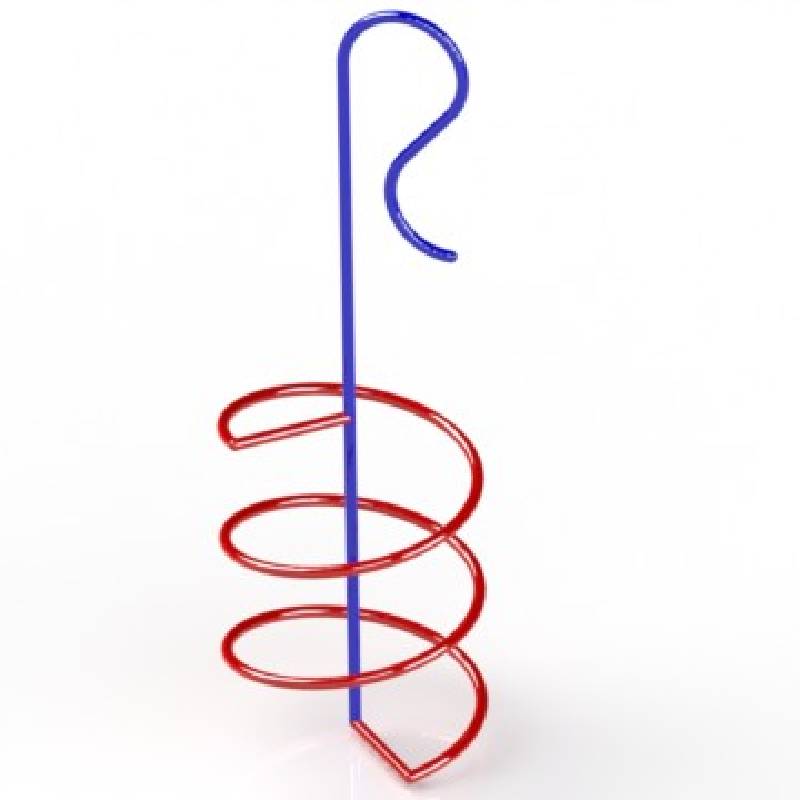

iron and wire

Iron and wire products have transcended their traditional roles to become indispensable in various industries. Their versatility and durability make them a preferred choice, but understanding their nuances requires a deep dive into their characteristics and applications.

Professionals such as civil engineers and metallurgists emphasize the importance of selecting the right type of iron or wire to maximize efficiency and longevity. Expertise in understanding material properties ensures the correct application, preventing premature failure and ensuring safety. The trustworthiness of iron and wire products is further validated by standards set by global organizations such as ASTM International and the International Organization for Standardization (ISO), ensuring they meet rigorous quality and safety criteria. Personal anecdotes from industry veterans reveal how innovations continue to emerge, such as using recycled iron and wire in sustainable construction projects. These experiences highlight not only the adaptability of these materials but also their role in advancing environmentally friendly practices. In conclusion, the depth of expertise surrounding iron and wire products is profound, with their reliability continuously proven across myriad applications. Their inherent qualities ensure they remain foundational in both traditional and modern industries, embodying a blend of historical significance and cutting-edge innovation. The experiences shared by professionals and consumers alike reinforce the ongoing trust in these materials, establishing them as authoritative solutions in both everyday and specialized applications.

Professionals such as civil engineers and metallurgists emphasize the importance of selecting the right type of iron or wire to maximize efficiency and longevity. Expertise in understanding material properties ensures the correct application, preventing premature failure and ensuring safety. The trustworthiness of iron and wire products is further validated by standards set by global organizations such as ASTM International and the International Organization for Standardization (ISO), ensuring they meet rigorous quality and safety criteria. Personal anecdotes from industry veterans reveal how innovations continue to emerge, such as using recycled iron and wire in sustainable construction projects. These experiences highlight not only the adaptability of these materials but also their role in advancing environmentally friendly practices. In conclusion, the depth of expertise surrounding iron and wire products is profound, with their reliability continuously proven across myriad applications. Their inherent qualities ensure they remain foundational in both traditional and modern industries, embodying a blend of historical significance and cutting-edge innovation. The experiences shared by professionals and consumers alike reinforce the ongoing trust in these materials, establishing them as authoritative solutions in both everyday and specialized applications.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025