製品導入

-

Model No.:

Automatic Rebar Tie Wire For Automatic Rebar

Tying Machine

Diameter:

0.8MM

長さ:

100M

Net weight:

0.4kg/ reel

Material Code:

Q195, Galvanized Wire

Applicable machine:

MAX RB392,395,397 and 213

Wire Tensile Strength

420m/Pa

Wire Yield Strength:

330m/Pa

Resistance against rust:

It should be no rust by 4cycles times under instructed test

conditions

Tensile Strength:

42-47 KG/CM2

Elongation:

21%

Wire length for one knot:

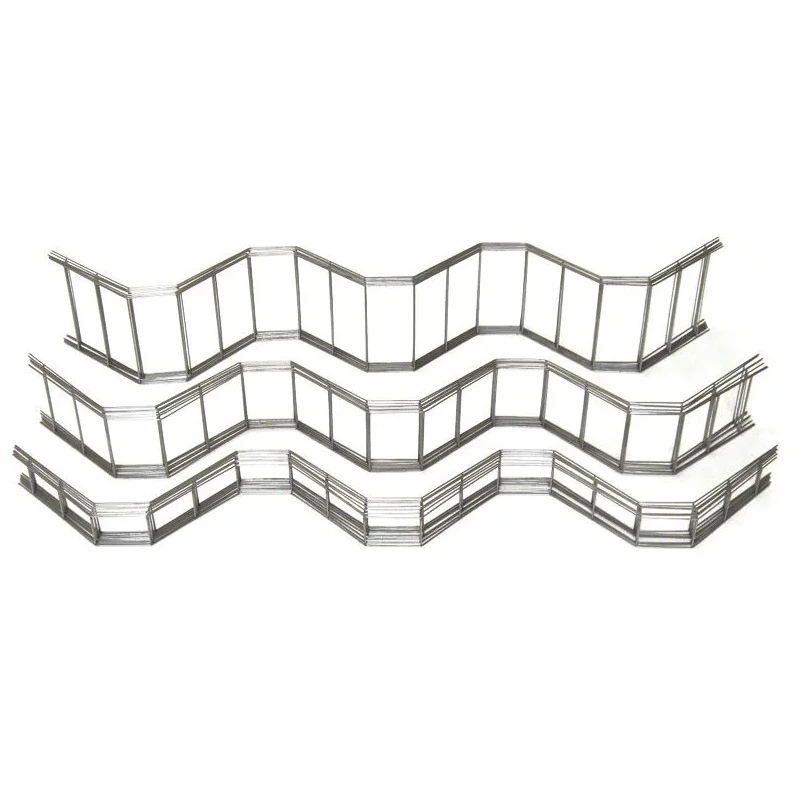

50-40cm.One reel can tie 120 to 190knots

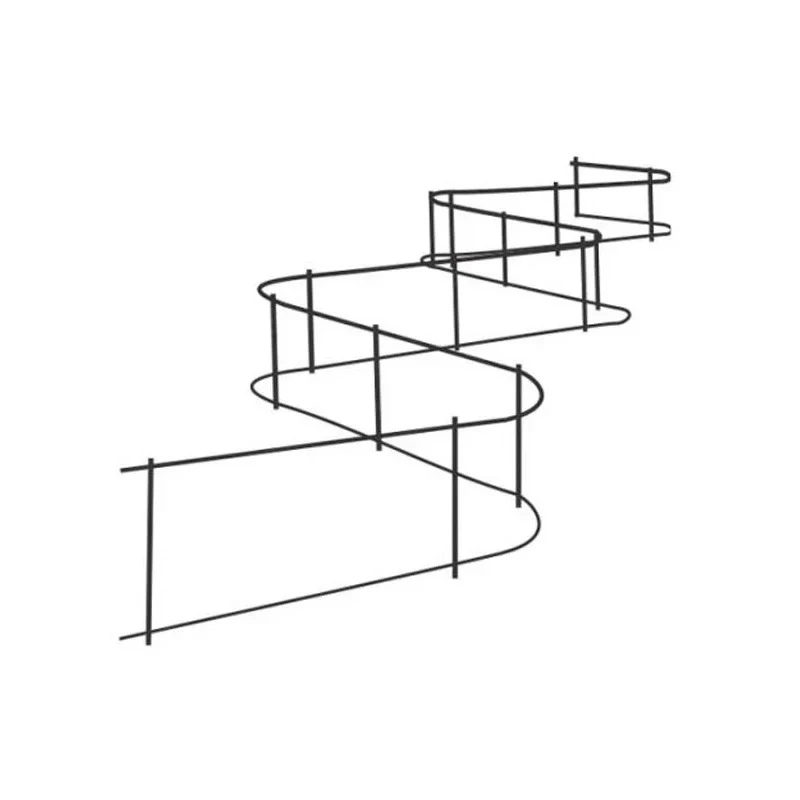

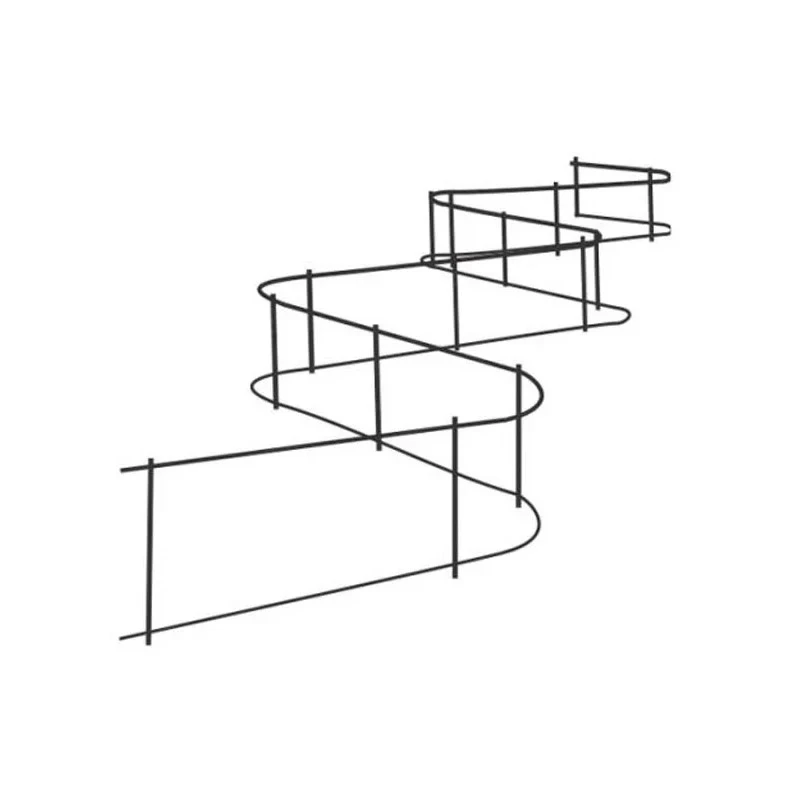

he steel wire for automatic rebar tying machine is a type of steel wire used in automatic rebar tying machines, with a diameter of 0.8mm and a length of up to 100 meters per roll. It is made of low-carbon steel and undergoes heat treatment, ensuring durability and stability. The surface of the steel wire is smooth, highly polished, and free of any burrs.

製品の利点

1. High quality and durability: Made of low-carbon steel and heat-treated, it has high strength and durability, ensuring long-term use.

2. Long length: The length of each roll of steel wire can reach 100 meters, reducing the frequency of replacing the steel wire and improving work efficiency.

3. Smooth surface: The surface of the steel wire is smooth, highly polished, and free of any burrs, ensuring that it will not scratch the rebar or other materials during use.

4. Wide application: Suitable for various automatic rebar tying machines, it is an ideal choice for construction sites, rebar processing plants, and other fields.

製品説明書

Usage method:

1. Install the steel wire: Install the steel wire on the automatic rebar tying machine to ensure a firm installation.

2. Set parameters: Set the parameters of the automatic rebar tying machine according to needs, such as tying force and speed.

3. Start the machine: Start the automatic rebar tying machine to allow it to perform the rebar tying operation automatically.

4. Replace the steel wire: Replace the steel wire when it is used up or when replacement is required, following the machine operating manual.

製品の製造工程

- Material selection: Select high-quality low-carbon steel materials to ensure the strength and durability of the steel wire.

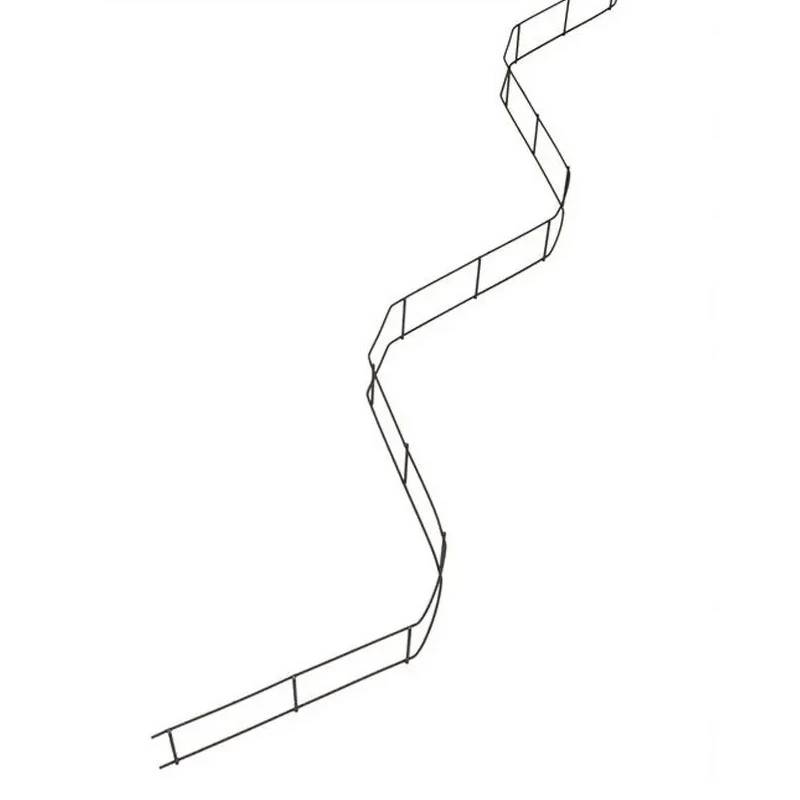

- Wire drawing process: Use professional wire drawing equipment to draw the raw materials into steel wires with a diameter of 0.8mm.

- Heat treatment: Carry out heat treatment on the steel wire to increase its strength and durability.

- Surface treatment: Adopt advanced surface treatment technology to make the surface of the steel wire smooth and free of any burrs.

Application scenarios:

製品の適用シナリオ

The steel wire for automatic rebar tying machines is widely used in construction sites, rebar processing plants, and other fields, and is suitable for tying of various automatic rebar tying machines, such as rebars, steel pipes, steel structures, etc.

Price advantage:

The price of the steel wire for automatic rebar tying machine is relatively low, which is an economically viable option. Its large-scale production and simple manufacturing process result in lower costs, thereby providing users with a competitive price.

-

パッキング

-