- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

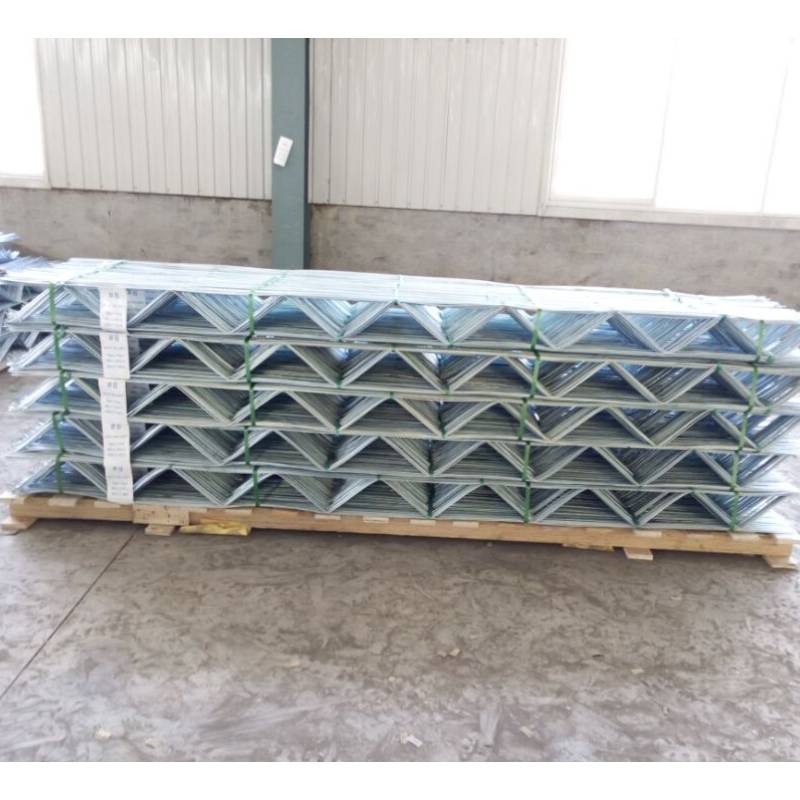

square welded wire mesh

Understanding Square Welded Wire Mesh Versatile Applications and Benefits

Square welded wire mesh is a widely utilized product in various industries due to its strength, durability, and versatility. It is made from high-quality steel wires that are welded at each intersection, forming a grid-like pattern of squares. This unique construction offers a range of benefits that make it an ideal choice for many applications.

Composition and Manufacturing Process

The manufacturing of square welded wire mesh begins with high tensile steel wires, which are drawn to specific diameters. These wires are then arranged into a grid formation and are welded at the intersections using advanced welding techniques. The welding process ensures the junctions are robust, providing increased structural integrity compared to other forms of wire mesh.

Depending on the intended application, square welded wire mesh can be coated with various materials to enhance its corrosion resistance. Zinc coating, for instance, is commonly used to protect the steel from environmental elements, thus extending the lifespan of the mesh. Other coatings, such as PVC, offer additional aesthetic appeal and chemical resistance.

Key Benefits of Square Welded Wire Mesh

1. Strength and Stability One of the most significant advantages of square welded wire mesh is its strength. The welded intersections create a solid structure that can withstand heavy loads, making it suitable for various demanding applications.

2. Versatile Applications This type of mesh is utilized in numerous industries. In construction, square welded wire mesh is often used as reinforcement in concrete slabs and walls, contributing to the overall structural integrity of buildings. It is also commonly used in fencing for residential and agricultural properties, providing secure boundaries while allowing visibility.

3. Cost-Effectiveness Square welded wire mesh is often more economically viable than other fencing or reinforcement solutions. Its durability ensures reduced maintenance and replacement costs over time, making it a cost-effective choice for many projects.

4. Ease of Installation The design and manufacturing process of square welded wire mesh allow for easy handling and installation. It can be cut to specific sizes and shapes without compromising its integrity, making it adaptable for various projects.

square welded wire mesh

5. Aesthetic Versatility In addition to its functional benefits, square welded wire mesh can also enhance the aesthetic appeal of a space. Available in various finishes and sizes, it can be used creatively in architectural designs, garden projects, and even art installations.

Common Applications

Square welded wire mesh is widely used in a variety of settings

- Agricultural Use It serves as fencing for livestock and enclosures for poultry, effectively preventing animals from escaping while allowing ventilation and natural light.

- Construction and Structural Support This mesh is often incorporated in concrete applications, reinforcing slabs and walls, increasing their strength and durability.

- Residential Fencing Homeowners use square welded wire mesh for secure fencing that provides visibility while maintaining safety.

- Safety Barriers It is also employed to create safety barriers in various environments, such as construction sites, warehouses, and industrial areas, preventing accidental falls or access to hazardous zones.

- Sifting and Screening In industries requiring material separation, such as mining and recycling, square welded wire mesh can be utilized for sifting or as screens to classify materials based on size.

Conclusion

Square welded wire mesh is a practical and versatile solution for a multitude of applications. Its combination of strength, durability, and cost-effectiveness makes it a preferred choice across various industries. Whether used in construction, agriculture, or residential settings, the benefits of square welded wire mesh are undeniable. As industries continue to evolve, the demand for this reliable material is likely to grow, further securing its place as a staple in engineering and construction. By understanding its characteristics and applications, stakeholders can make informed decisions and leverage this valuable resource for their projects.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025