- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

compression spring design calculations pdf

Understanding Compression Spring Design Calculations

Compression springs are one of the most commonly used types of springs in various mechanical applications. Their design and performance are critical to ensure functionality, longevity, and efficiency in devices ranging from simple toys to complex industrial machinery. This article delves into the essential aspects of compression spring design calculations.

Basic Principles of Compression Springs

A compression spring is designed to resist compressive forces. When a load is applied, the spring compresses, storing potential energy that can be released when the load is removed. The efficacy of a compression spring is determined by factors such as material, wire diameter, spring diameter, number of active coils, and the overall spring length.

Material Selection

Selecting the right material is the first step in designing a compression spring. Common materials include stainless steel, carbon steel, and alloy steel, each offering different mechanical properties. Stainless steel is often preferred for its corrosion resistance, while carbon steel is chosen for its strength and resilience. The material’s tensile strength has a direct impact on the spring's ability to withstand loads without deforming.

Key Design Calculations

1. Spring Constant (k) The spring constant, or stiffness, is calculated using the formula

\[ k = \frac{Gd^4}{8D^3n} \]

where \(G\) is the modulus of rigidity, \(d\) is the wire diameter, \(D\) is the spring diameter, and \(n\) is the number of active coils

. The spring constant signifies how much force is needed to compress the spring a certain distance.compression spring design calculations pdf

2. Maximum Load (F) The maximum load that a compression spring can handle without yielding can be determined using

\[ F = k \cdot x \]

where \(x\) is the maximum compression. This relationship helps in ensuring that the spring will function properly under specific loading conditions.

3. Fatigue Life Compression springs are subject to repeated loading, making fatigue life an important consideration. The endurance limit can often be estimated using

\[ \sigma_{max} \leq \frac{0.5 \times \sigma_{uts}}{SF} \]

where \(\sigma_{uts}\) is the ultimate tensile strength of the material and \(SF\) is the safety factor. This calculation aids in predicting how long a spring will last before experiencing fatigue failure.

Spring Geometry

The physical dimensions of the spring, including the overall diameter, free length, and the number of coils, significantly influence performance. A larger diameter typically offers a lower spring constant but allows for greater deflection. Conversely, an increase in the number of active coils tends to lower the spring constant, enhancing its flexibility.

Conclusion

The design of compression springs requires careful consideration of material properties, geometric factors, and loading conditions. By comprehensively understanding the key calculations involved—such as spring constant, maximum load, and fatigue life—engineers can create efficient and reliable compression springs for various applications. As industries continue to evolve, the demand for optimized spring design will only increase, making these calculations and principles even more critical in modern engineering practices.

share:

-

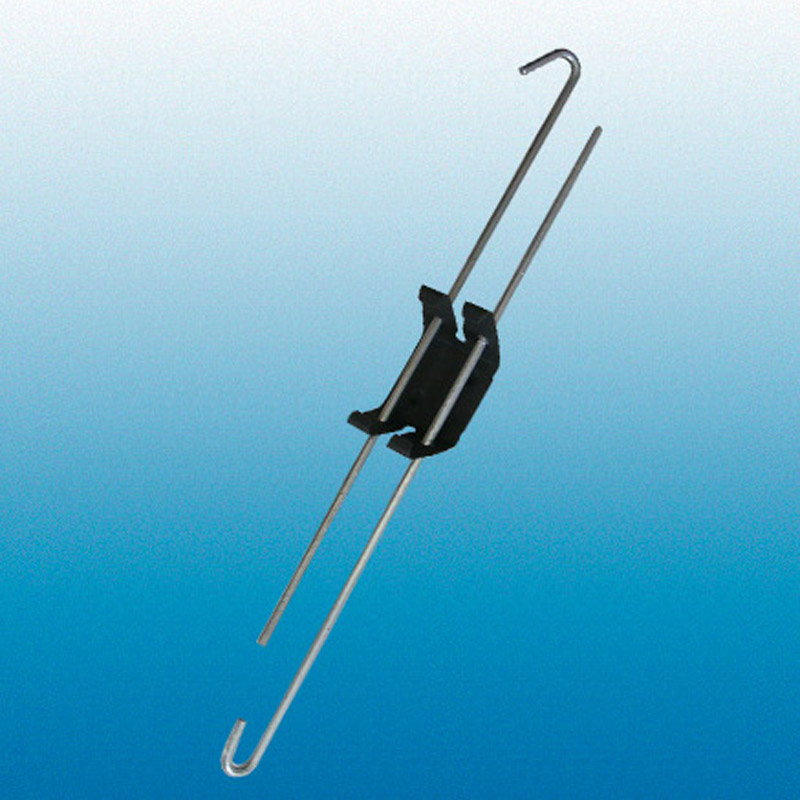

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025