- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Premium High Rib Lath for Stucco & Plaster | Durable & Easy Install

Introduction to High Rib Lath in Modern Construction

In the realm of B2B construction and infrastructure, material selection plays a pivotal role in project longevity, structural integrity, and overall cost-efficiency. Among the indispensable materials, high rib lath stands out as a superior expanded metal solution, engineered to provide exceptional reinforcement for plaster, stucco, and fireproofing applications. This specialized lath, characterized by its unique rib design, significantly enhances the mechanical keying and bond strength of applied finishes, offering unparalleled performance compared to conventional flat lathing products.

Its robust design and material versatility make it a preferred choice across diverse industries, from high-rise commercial developments to complex industrial facilities. This article delves into the technical intricacies, application advantages, and market trends surrounding high rib lath, providing essential insights for B2B decision-makers, engineers, and procurement specialists seeking optimal material solutions.

Current Industry Trends and Market Dynamics

The construction industry is continually evolving, driven by demands for greater sustainability, enhanced structural performance, and accelerated project timelines. These trends directly influence the demand for advanced materials like high rib lath. There's a growing emphasis on materials that contribute to energy efficiency, particularly in insulation and fireproofing systems where the lath acts as a crucial substrate. Environmental regulations are also pushing for the use of galvanized or stainless steel variants to ensure longer service life and reduced maintenance, aligning with sustainable building practices.

The global market for construction materials sees steady growth, with a particular uptick in specialized products offering superior performance. The demand for facade systems, including those utilizing `stucco rib lath`, is increasing in both commercial and residential sectors. Furthermore, the push for prefabrication and modular construction methods necessitates materials that are easy to install and integrate, which high rib lath inherently offers due to its rigidity and self-furring properties. This also impacts the logistics and services provided by `rib lath suppliers`, who are increasingly expected to offer just-in-time delivery and tailored solutions.

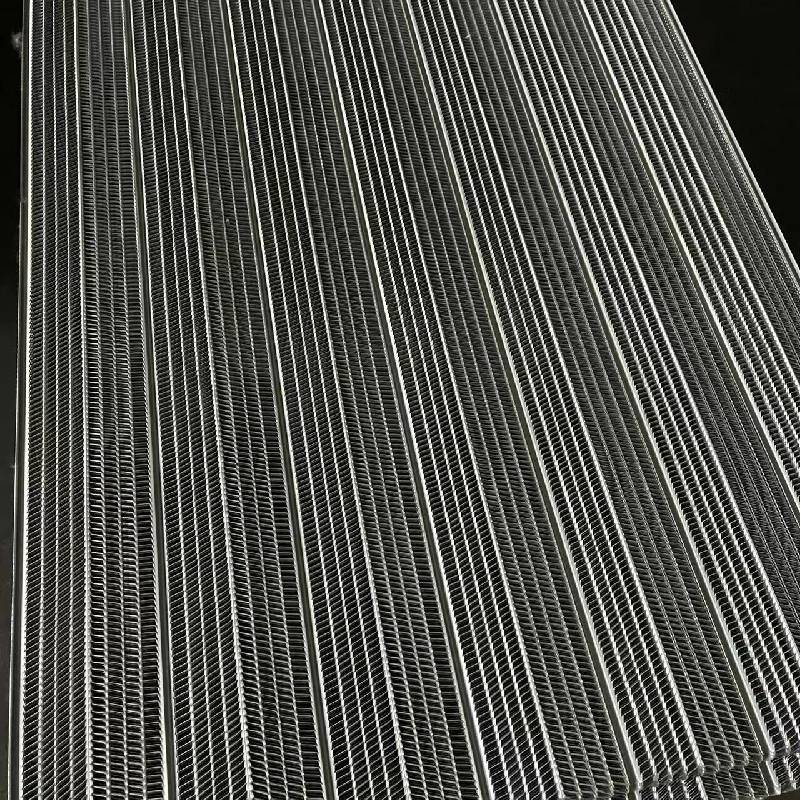

Image 1: Close-up of high rib lath showcasing its unique rib structure.

Beyond traditional lathing, related product categories such as `steel welded wire fence`, `aluminum woven wire mesh`, `stainless wire fence`, `grid fencing`, and `wire link fence` also see robust demand, often in complementary applications for security, demarcation, or specialized filtration. While distinct, these products share common manufacturing principles and material science expertise with expanded metal products, indicating a broader market trend towards durable, high-performance metallic mesh solutions.

Technical Specifications and Manufacturing Process

Product Materials and Structure

High rib lath is typically manufactured from galvanized steel, offering excellent corrosion resistance, or occasionally from stainless steel for extremely demanding environments. The design features a series of longitudinal ribs, usually 8 to 12mm deep, spaced uniformly across the sheet. These ribs provide structural rigidity, allowing for wider spacing of support studs and self-furring properties, which create a consistent plaster key. The mesh pattern between the ribs, formed through an expanding process, ensures optimal mechanical bonding for various finishing materials. Common material grades include G90 galvanized steel (ASTM A653) for standard applications and various grades of stainless steel (e.g., 304 or 316) for enhanced chemical resistance.

Detailed Manufacturing Process Flow

The production of high rib lath involves a precise sequence of operations, ensuring consistent quality and performance:

- Material Procurement: High-quality steel coils (typically galvanized steel or stainless steel) are sourced from certified mills, adhering to international standards such as ASTM A653 for galvanized steel.

- Slitting: The large steel coils are precisely slit into narrower strips, or blanks, corresponding to the desired width of the finished lath. This ensures accurate dimensions and minimizes material waste.

- Expanding (Punching & Slitting): The strips undergo a specialized expanding process. This involves simultaneous punching and slitting of the metal in a staggered pattern, creating the diamond-shaped openings (mesh). This process, unlike forging or CNC machining, is highly efficient for mesh production.

- Rib Forming: Immediately after or concurrently with the expanding process, a series of rollers form the distinctive longitudinal ribs in the lath. These ribs are crucial for the product's rigidity and self-furring capability.

- Flattening (Optional): Depending on the specific product requirement, some forms of expanded metal lath may undergo a flattening process. For high rib lath, the ribs are maintained to maximize rigidity.

- Shearing and Cutting: The continuous lath sheets are then sheared to specific lengths, typically 2.5m or 3.0m, according to market standards or custom orders.

- Quality Control and Testing: Each batch undergoes rigorous quality control. This includes dimensional checks (width, length, rib height, mesh opening size), material thickness verification, and visual inspection for defects. Compliance with international standards such as ISO 9001 for quality management and ASTM C847 for metal lath is strictly maintained. Performance tests, like pull-out strength for plaster adhesion, may also be conducted.

- Packaging: Finished sheets are bundled, typically 10 or 20 sheets per bundle, and secured for safe transportation to clients or distributors, often wrapped to protect against environmental damage.

The manufacturing process is highly automated, ensuring precision and consistency across large production volumes, which is critical for projects demanding uniform material properties. The robust nature of the galvanized coating ensures an extended service life, typically exceeding 20-30 years in standard building environments, making it a highly durable solution.

Key Product Specification Table

| Parameter | Specification Range | Relevant Standard |

|---|---|---|

| Material | Hot-dipped Galvanized Steel (G60/G90), Stainless Steel (304, 316) | ASTM A653, ASTM A240 |

| Sheet Width | 610 mm - 762 mm (24" - 30") | ASTM C847 |

| Sheet Length | 2440 mm - 3050 mm (8' - 10') | ASTM C847 |

| Rib Depth | 8 mm - 12 mm (3/8" - 1/2") | Internal QC |

| Base Metal Thickness | 0.25 mm - 0.5 mm (28 - 25 Gauge) | ASTM A653 |

| Weight per Square Meter | 0.4 kg/m² - 0.7 kg/m² | Calculated |

Image 2: Manufacturing process of high rib lath illustrating automated production.

Application Scenarios and Technical Advantages

Versatile Application Across Key Industries

The inherent strength and adaptability of high rib lath make it invaluable across a multitude of industrial and commercial sectors. Its primary role is to provide a robust, stable base for various applied finishes:

- Construction and Architecture: Widely used for plaster and `stucco rib lath` applications on internal and external walls, ceilings, columns, and soffits. It is crucial for creating smooth, durable surfaces and enhancing the fire resistance of structural elements. Its rigidity supports heavier plaster coats, making it suitable for high-traffic areas or areas requiring increased thermal mass.

- Petrochemical Plants: In environments exposed to corrosive elements and high temperatures, high rib lath provides essential support for fireproofing materials around pipes, vessels, and structural steel. Its corrosion resistance (especially in stainless steel variants) ensures the long-term integrity of insulation and protective coatings, contributing to energy saving and operational safety.

- Metallurgy and Heavy Industry: Similar to petrochemical, these sectors utilize the lath for reinforcing refractory linings, insulation, and fire barriers in furnaces, kilns, and processing equipment, where extreme temperatures and mechanical stresses are common.

- Water Supply & Drainage Infrastructure: Used in the construction and renovation of water treatment plants, pumping stations, and underground conduits. Here, its corrosion resistance and ability to support waterproof membranes or protective coatings are vital for long-term infrastructure resilience.

- Fireproofing Systems: Critical in creating robust fire-rated enclosures for structural steel, ductwork, and critical egress paths. The lath provides the necessary mechanical key for cementitious and gypsum-based fireproofing sprays, enhancing their adhesion and preventing delamination.

Core Technical Advantages

- Superior Adhesion and Keying: The deeply formed ribs and expanded mesh design create an unparalleled mechanical key for plaster and stucco, significantly improving adhesion and reducing the risk of cracking, delamination, and future repairs. This is a primary driver for its selection over other lathing types.

- Enhanced Structural Rigidity: The longitudinal ribs provide exceptional stiffness to the lath, allowing for wider stud spacing and reducing the need for extensive framing. This translates into material savings and faster `rib lath installation` times.

- Self-Furring Capability: The rib design naturally elevates the lath from the substrate, creating a consistent airspace that ensures uniform plaster thickness and prevents sagging. This eliminates the need for separate furring strips, streamlining the installation process.

- Corrosion Resistance: Galvanized steel, with its zinc coating, provides robust protection against rust and environmental degradation, extending the service life of the lath and the integrity of the overall system. Stainless steel options offer even greater resistance in highly corrosive or marine environments.

- Fire Resistance Contribution: By securely holding fireproofing materials, high rib lath plays a critical role in achieving specified fire-resistance ratings for structural elements, enhancing building safety.

- Material Efficiency: The expanded metal manufacturing process is highly efficient, producing a large surface area from a relatively small amount of material, which can lead to cost efficiencies without compromising strength.

Image 3: Installation of high rib lath on a construction site, demonstrating its ease of application.

Vendor Comparison and Customized Solutions

Selecting the Right Rib Lath Suppliers

When evaluating `rib lath suppliers`, several critical factors must be considered to ensure optimal project outcomes. Beyond the basic product specifications, the reliability, expertise, and service capabilities of the vendor are paramount. Here’s a comparison framework:

| Evaluation Criterion | Standard Supplier Offerings | Premium Supplier (e.g., CNTC Metal) Advantages |

|---|---|---|

| Material Quality & Standards | Basic galvanized steel; compliance with minimum local standards. | High-grade galvanized (G90) and marine-grade stainless steel; certified to ASTM, ISO, and country-specific structural codes. Decades of consistent material excellence. |

| Product Range & Customization | Limited stock sizes and gauges; minimal customization options. | Extensive standard inventory; full customization for dimensions, rib depth, mesh pattern, and material types to meet unique project specifications. |

| Certifications & Authoritativeness | May lack comprehensive certifications or third-party validation. | ISO 9001, ASTM C847, and relevant national building code approvals. Proven track record over 20+ years of service with major industry partners. |

| Technical Support & Expertise | Basic product information; limited engineering support. | Dedicated engineering teams for design consultation, installation guidance, and problem-solving. Deep understanding of `rib lath installation` best practices. |

| Lead Time & Fulfillment | Standard lead times; less flexibility for urgent orders. | Efficient production cycles; capability for expedited orders and global logistics, minimizing project delays. |

| After-Sales Service | Limited warranty, minimal post-purchase support. | Comprehensive warranty, dedicated customer support, and on-site assistance for complex projects. |

Tailored Customized Solutions

Recognizing that no two projects are identical, leading `rib lath suppliers` like CNTC Metal offer extensive customization options for high rib lath. This can include specific sheet dimensions, unique rib depths for specialized plaster thicknesses, alternative material compositions (e.g., particular stainless steel alloys for extreme chemical resistance), or even custom hole patterns to optimize adhesion for novel rendering materials. This flexibility ensures that the lath integrates seamlessly into diverse architectural and engineering designs, providing precise performance characteristics required for critical applications. Collaborative design processes with clients are a hallmark of expert suppliers, ensuring the final product meets exact structural and aesthetic criteria.

Image 4: Stored bundles of high rib lath ready for dispatch to construction projects.

Application Case Studies

Case Study 1: High-Rise Commercial Tower Facade

Project: Façade system for a 40-story commercial office tower in a coastal city.

Challenge: The project required a durable, weather-resistant stucco facade that could withstand high winds, seismic activity, and saline air, while also accommodating the building's thermal expansion and contraction. Conventional lathing showed tendencies to crack under these stresses.

Solution: Over 100,000 square meters of galvanized high rib lath with 10mm rib depth were specified. The lath’s superior rigidity allowed for wider stud spacing (reducing framing material costs) and its robust keying properties provided an exceptional bond for the three-coat stucco system. Its inherent self-furring design simplified `rib lath installation` and ensured uniform stucco thickness.

Outcome: The facade demonstrated excellent long-term integrity, with no significant cracking or delamination observed after five years. The project team reported a 15% reduction in lath installation time compared to flat lath, contributing to overall project efficiency and cost savings.

Case Study 2: Industrial Furnace Fireproofing Reinforcement

Project: Upgrading the fireproofing and insulation system for a large industrial furnace in a metallurgy plant.

Challenge: The furnace operates at extreme temperatures, and its existing fireproofing material was prone to degradation and spalling due to thermal cycling and vibrations. A robust, long-lasting reinforcement was needed.

Solution: Stainless steel (316 grade) high rib lath was selected for its superior corrosion and heat resistance. It was securely fastened around the furnace's structural components to act as a robust substrate for a high-density, spray-applied refractory coating. The deep ribs provided maximum mechanical interlock, critical for retaining the dense, heavy fireproofing material under severe conditions.

Outcome: The reinforced fireproofing system significantly improved the furnace’s thermal efficiency and operational safety. Post-installation inspections and temperature cycling tests confirmed the excellent adhesion and stability of the refractory material. This contributed to enhanced energy saving and reduced maintenance downtime for the facility.

Commitment to Trust and Support

Frequently Asked Questions (FAQ)

Q: What is the primary advantage of high rib lath over standard expanded metal lath?

A: The key advantage of high rib lath lies in its robust, deeply formed ribs which provide exceptional rigidity, superior plaster keying, and self-furring properties. This leads to stronger, more crack-resistant surfaces and simplified installation, especially for thicker applications.

Q: Can high rib lath be used for exterior stucco applications?

A: Absolutely. High rib lath, especially galvanized steel variants, is an excellent choice for exterior stucco (stucco rib lath) due to its durability, corrosion resistance, and ability to securely hold heavier stucco coats against environmental stresses.

Q: What are the typical lead times for custom high rib lath orders?

A: Standard stock orders can typically be fulfilled within 3-5 business days. For customized solutions involving specific materials or dimensions, lead times generally range from 2-4 weeks, depending on complexity and order volume. We work closely with clients to meet project deadlines.

Q: What kind of warranty is offered on your high rib lath products?

A: We provide a comprehensive warranty covering material defects and manufacturing faults for a period of 10 years from the date of purchase. Our products are designed and manufactured to meet or exceed industry standards, ensuring reliable performance.

Lead Time and Fulfillment

At CNTC Metal, we understand the critical nature of project schedules. Our advanced manufacturing capabilities and extensive inventory allow for rapid fulfillment of standard high rib lath orders. For specialized or large-volume requests, our team provides transparent lead time estimates and works diligently to optimize production and logistics to meet your specific delivery requirements, maintaining consistent communication throughout the process.

Warranty and After-Sales Support

We stand behind the quality and performance of our high rib lath products with a robust warranty. Our commitment extends beyond delivery, with a dedicated after-sales support team available to assist with any technical queries, installation guidance, or performance concerns. We offer comprehensive documentation, expert consultation, and prompt issue resolution to ensure complete customer satisfaction and the long-term success of your projects.

Conclusion

The selection of appropriate building materials is paramount for the success and longevity of any construction or industrial project. High rib lath offers a technologically advanced and highly effective solution for plaster, stucco, and fireproofing reinforcement, delivering superior adhesion, structural integrity, and ease of installation. By understanding its technical specifications, manufacturing processes, and diverse application benefits, B2B stakeholders can make informed decisions that contribute to enhanced safety, efficiency, and cost-effectiveness across their ventures. Partnering with experienced `rib lath suppliers` who offer quality products, customization, and robust support is essential for leveraging the full potential of this critical material.

References

- American Society for Testing and Materials. (2020). ASTM C847/C847M-20, Standard Specification for Metal Lath. ASTM International.

- American Society for Testing and Materials. (2022). ASTM A653/A653M-22, Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. ASTM International.

- International Organization for Standardization. (2015). ISO 9001:2015, Quality management systems – Requirements. ISO.

- Portland Cement Association. (2006). Stucco: Best Practices for Installation. PCA.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025