- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

weld mesh for concrete

The Role of Welded Wire Mesh in Concrete Construction

In the realm of construction, the integrity and durability of structures are paramount. One of the key materials that has gained significant traction over the years is welded wire mesh (WWM), particularly in concrete applications. This versatile product enhances the strength of concrete, making it a preferred solution in various construction projects.

Understanding Welded Wire Mesh

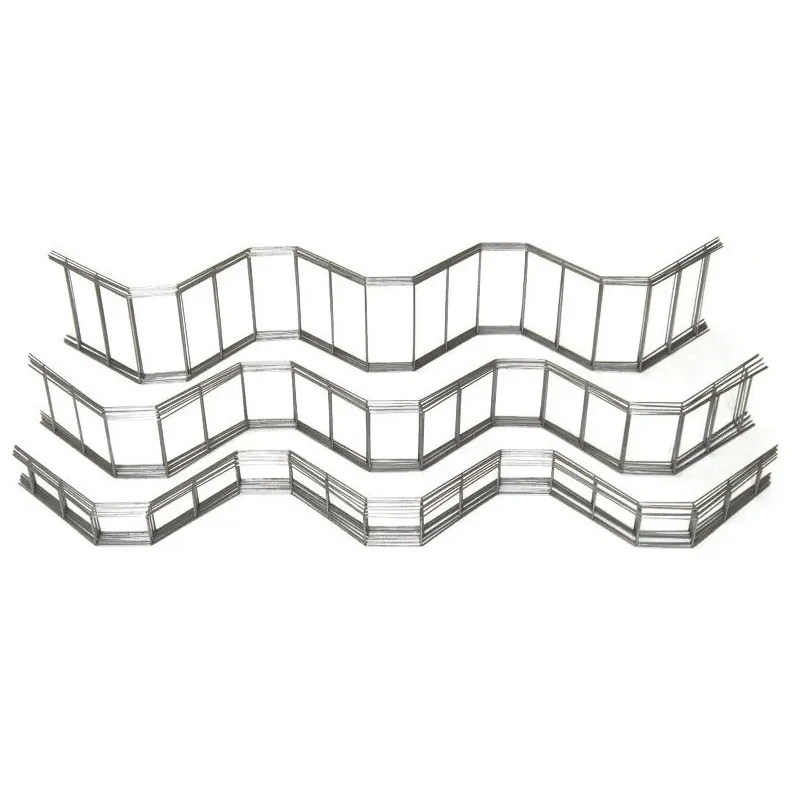

Welded wire mesh is a grid-like structure made from high-quality steel wires that are welded together at each intersection. These meshes are typically produced in sheets or rolls and are available in various sizes and configurations, allowing for flexibility in design and application. The strength and durability of welded wire mesh make it particularly well-suited for reinforcing concrete.

Benefits of Using Welded Wire Mesh in Concrete

1. Improved Structural Integrity One of the primary advantages of using welded wire mesh in concrete is the enhancement of structural integrity. The mesh evenly distributes loads across the surface of the concrete, minimizing the risk of cracking and increasing overall stability. This is particularly important in areas subjected to heavy loads or extreme weather conditions.

2. Ease of Installation Welded wire mesh is relatively easy to handle and install. Its lightweight nature allows for quick placement, reducing labor costs and construction time. Unlike traditional reinforcement methods, such as rebar, welded wire mesh can be laid down swiftly with minimal fuss, making it an efficient choice for contractors.

3. Cost-Effectiveness The initial investment in welded wire mesh may be higher than other reinforcement materials, but its cost-effectiveness becomes apparent in the long run. By enhancing durability and reducing the likelihood of repairs, welded wire mesh ultimately saves money on maintenance and replacements.

4. Versatility Welded wire mesh can be utilized in a wide variety of applications, including slabs, walls, pavements, and precast concrete elements. This versatility extends to different concrete grades and types, making it suitable for residential, commercial, and industrial projects.

weld mesh for concrete

5. Enhanced Aesthetic Appeal In addition to its structural benefits, welded wire mesh can also improve the aesthetic qualities of a concrete surface. It allows for a smoother finish and can be incorporated into decorative concrete applications. Furthermore, it can be used in combination with other materials, such as exposed aggregate finishes, to achieve a desired aesthetic.

Application in Different Environments

The use of welded wire mesh is not limited to any one type of environment. It performs admirably in both wet and dry applications, making it ideal for regions with varying climates. It has proven effective in agricultural settings, industrial floors, driveways, walkways, and even in high-stress environments like bridge decks and parking structures.

Additionally, its resistance to corrosion can be enhanced through galvanization or the use of stainless steel, which makes it suitable for use in aggressive environments where concrete is exposed to moisture and other corrosive substances.

Environmental Impact

As the construction industry continues to evolve, there is an increasing focus on sustainability. Welded wire mesh contributes to this goal by reducing the amount of concrete needed while maintaining structural integrity. Its strength allows for thinner slabs and reduced material usage, thereby decreasing the overall carbon footprint of concrete construction. Furthermore, the use of recycled materials in the production of welded wire mesh further supports environmentally friendly practices.

Conclusion

Welded wire mesh is an indispensable component in modern concrete construction. Its numerous benefits—including improved structural integrity, ease of installation, cost-effectiveness, versatility, and aesthetic appeal—make it a preferred choice for builders and engineers alike. As sustainability becomes a key focus in the industry, the use of welded wire mesh aligns with initiatives to reduce material waste and promote environmentally friendly practices. As technology advances, the future of welded wire mesh in concrete construction looks promising, ensuring safer and more durable structures for years to come.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025