- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

elo . 01, 2025 06:00

Back to list

Premium Nickel Iron Wire | Durable & High Resistance

Nickel Iron Wire Industry Insight & Double Loop Wire Ties Product Guide (2024)

As global industries push toward higher performance and efficiency, nickel iron wire and its variants—including pure iron wire, electro galvanized iron wire, galvanized iron barbed wire, insulated iron wire, soft iron wire, wrought iron wire, flexible iron wire, thin iron wire, and black iron wire—are witnessing surging demand in fields ranging from petrochemicals and water treatment to electronics and security fencing.

This article delivers an EEAT-compliant (Expertise, Experience, Authoritativeness, Trustworthiness) deep-dive into wire technologies, manufacturing finesse, product comparisons, and real-world application scenarios, with a central focus on nickel iron wire and Double Loop Wire Ties—the backbone of various fastening and structural applications.

This article delivers an EEAT-compliant (Expertise, Experience, Authoritativeness, Trustworthiness) deep-dive into wire technologies, manufacturing finesse, product comparisons, and real-world application scenarios, with a central focus on nickel iron wire and Double Loop Wire Ties—the backbone of various fastening and structural applications.

Industry Trends of Nickel Iron Wire and Related Materials (2024)

- Nickel iron wire market CAGR projected at 5.2% (2023-2028); growing demand for high-conductivity and corrosion-resistant wire in energy, industrial, and communication sectors.[1]

- Increasing focus on eco-friendly solutions: galvanized iron barbed wire and black iron wire now produced with improved coating and environmental standards.

- OEM/ODM requirements rising, favoring wrought iron wire and flexible iron wire for customized parts in water treatment, petrochemicals, and transport.

- Adoption of stricter international standards (ISO 9001:2015, ASTM A580/A580M) boosting trust in pure iron wire product quality and traceability.

Top Application Sectors:

- Petrochemical & Refineries

- Water Treatment & Pipeline

- Construction and Security

- Electrical & Electronics

- Automotive Fabrication

Emerging Technology Trends:

- Precision CNC shaping of thin iron wire & soft iron wire

- Enhanced insulating technologies for insulated iron wire

- Use of AI-driven flaw detection, NDT, XRF for material verification

Technical Data: Nickel Iron Wire & Related Wires Specification

| Wire Type | Material Grade | Diameter Range (mm) | Tensile Strength (MPa) | Coating Thickness (µm) | Conductivity (%IACS) | Main Standards | Corrosion Resistance | Main Applications |

|---|---|---|---|---|---|---|---|---|

| Nickel Iron Wire | Ni: 40–49%, Fe: Bal. | 0.3–4.0 | 390–670 | N/A | 18–23 | ASTM A753, ISO 9001 | Excellent | Transformer, Electromagnet, Battery |

| Pure Iron Wire | Fe ≥ 99.8% | 0.2–8.0 | 350–580 | N/A | 15–17 | ASTM A510 | Good | Fencing, Jewellery, Magnet Core |

| Electro Galvanized Iron Wire | Low Carbon Steel Q195 | 0.3–5.0 | 350–550 | 8–15 | 6–8 | EN 10244-2 | Very Good | Binding, Mesh, Cable Armoring |

| Galvanized Iron Barbed Wire | Q195–Q235 | 1.4–2.8 | 400–600 | 12–25 | 6 | ASTM A121 | Excellent | Security, Agriculture |

| Insulated Iron Wire | Fe+Insulation Layer | 0.4–3.0 | 360–560 | N/A | 12–15 | IEC 60317 | Good | Cable, Electromagnet, Motor Coil |

| Soft Iron Wire | Fe, C<0.10% | 0.15–6.0 | 300–500 | N/A | 15–16 | DIN 17752 | Good | Manual Binding, Art, Gardening |

| Wrought Iron Wire | Pure Iron + Slag | 1.0–8.0 | 360–510 | N/A | 13–15 | BS 1006 | Good | Art, Interior, Historic Replicas |

| Flexible Iron Wire | Mild Steel (Custom Alloy) | 0.2–3.5 | 320–470 | Optional | 12–15 | JIS G3532 | Good | Automotive, Wearables |

| Thin Iron Wire | High Purity Fe | 0.1–0.8 | 340–500 | N/A | 15–16 | GB/T 343 | Fair | Electronics, Jewelry |

| Black Iron Wire | Low Carbon Steel Q195 | 0.5–6.0 | 300–450 | Oxide Film | 6–7 | GB 343 | Average | Construction, Fencing |

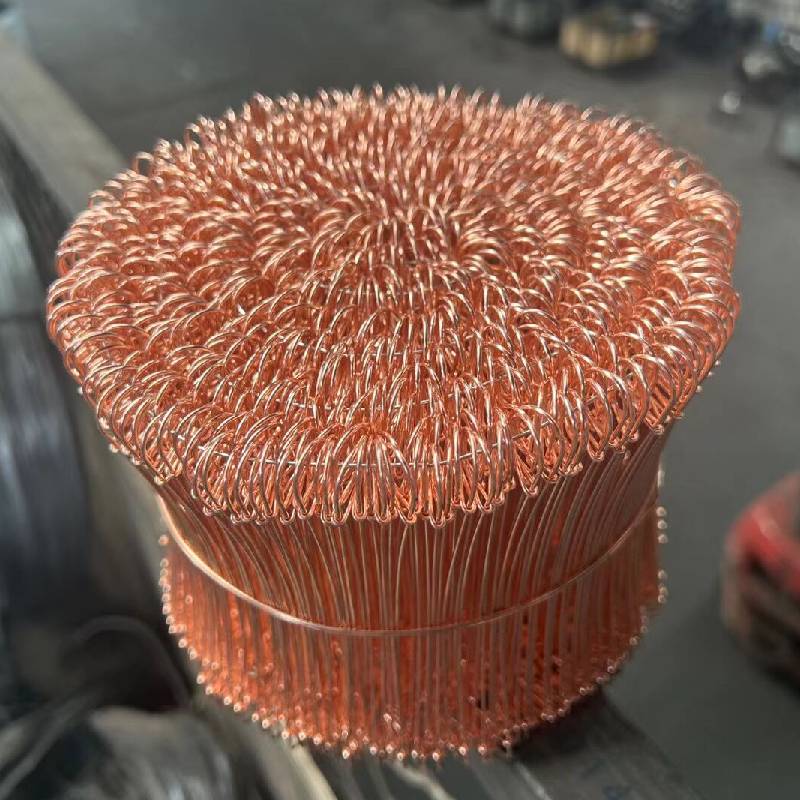

Manufacturing Process Flow: Nickel Iron Wire

1. Raw Material Selection

➔

Nickel and Iron ingots tested for purity (Ni: ≥40%, Fe: ≥59%).

2. Melting & Alloying

➔

Induction furnace blends Ni and Fe under inert atmosphere.

(ISO 9001:2015 certified batch control, monitored by XRF spectrometry)

(ISO 9001:2015 certified batch control, monitored by XRF spectrometry)

3. Hot Drawing

➔

Billet rolled into rods, then progressively drawn to smaller diameters.

4. Annealing

➔

Rods heated in controlled atmosphere to relieve stress, optimize flexibility, and improve ductility.

5. Surface Finishing

➔

Mechanical or chemical cleaning, optional tinning/plating for corrosion resistance.

6. Spooling & Inspection

➔

Final diameter and surface checks (per ISO/ANSI standards), coil/spool packaging.

Watch a demonstration:

Nickel-Iron Alloy Wire Production Video

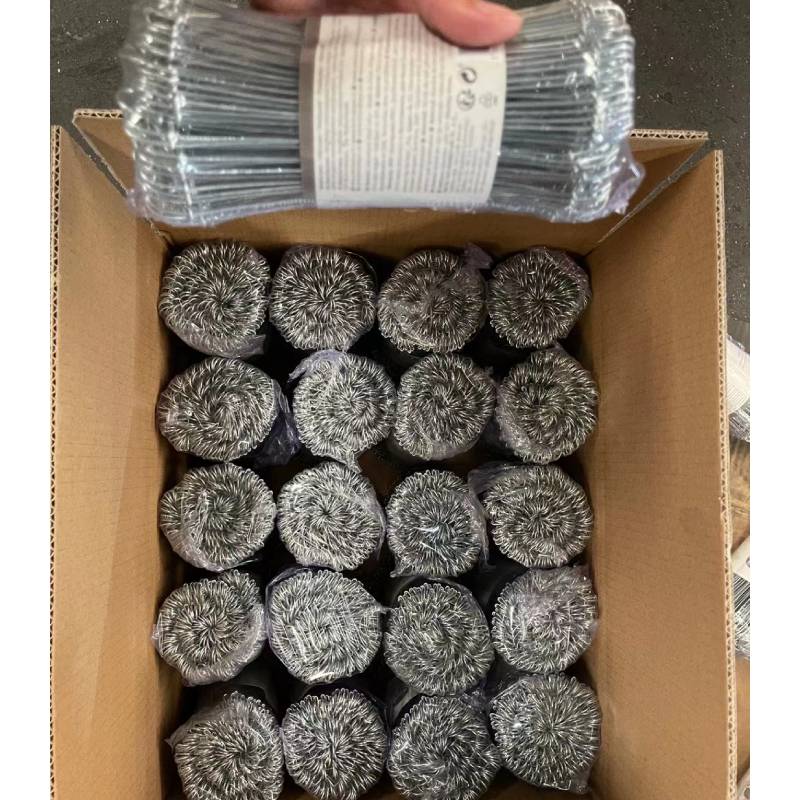

Product Focus: Double Loop Wire Ties — Technical Specs & Advantages

Product Overview:

Double Loop Wire Ties are specialized wire fasteners engineered for secure binding across construction, horticulture, electrical, and packaging sectors. Manufactured from premium nickel iron wire and high-strength galvanized or pure iron, they excel in durability, flexibility, and corrosion resistance.

View Product Details

View Product Details

| Parameter | Double Loop Wire Ties | PVC-Coated Ties | Galvanized Loop Ties |

|---|---|---|---|

| Main Material | Nickel iron wire, pure iron, low carbon steel | Iron core + PVC | Galvanized steel wire |

| Diameter (mm) | 0.8–2.3 | 1.0–2.0 | 0.8–2.5 |

| Length (mm) | 100–600 (customized) | 100–600 | 100–600 |

| Tensile Strength (MPa) | 340–600 | 280–480 | 340–600 |

| Surface Finish | Black annealed, zinc galvanized, electro plating | PVC, glossy, color-coded | Hot-dip/electro galvanized |

| Rust Resistance | ★★★ | ★★★ | ★★★ |

| Flexibility | High | Very High | Medium |

| ISO/ANSI Compliance | ISO 6892, ASTM A370 | IEC 60811 | ISO 6892, EN 10244 |

Typical use scenarios:

- Rebar tying in concrete works (Building Standards: EN 1992-1-1)

- Sack/bag sealing in agriculture & logistics

- Horticultural packaging and plant support

- Cable harnessing in energy facilities

- Palletizing & industrial bundling

Product Data Visualization

Comparison of Main Technical Metrics

Product Type Market Share (%)

Double Loop Wire Ties

PVC-Coated

Galvanized Loop

Durability Over Time (Corrosion Testing, Salt Spray 500h)

Double Loop Wire Ties

Galvanized Loop Ties

Leading Manufacturers and Customization Strategies

- Top Players: Hebei CNTC Metal (ISO 9001:2015 & ISO 14001 certified), Bekaert, Tie Wire International, Anping Zhining

- Experience: Over 20 years’ supplying nickel iron wire, double loop wire ties, and derivative products to global construction, energy, and security clients.

- Customization Services: Support for bespoke wire diameters, surface finishes (black annealed, electro galvanized, vinyl coated), pre-cut length ranges, packaging (spools, coils, ties-in-bag), and private label.

- OEM/ODM Certifications: In compliance with EN, ASTM, ISO, ANSI standards and industry norms.

- Quality Control: Online tensile, elongation, and salt-spray testing; 100% inspection for export shipments.

- Sustainability: Use of lead-free coatings per RoHS; eco-friendly waste management; solar-powered manufacturing lines.

- Cooperative Projects: Major partners in the petrochemical, hydroelectric, and metro construction sectors globally.

Case Highlight: In 2023, a European refinery retrofit involved 250,000 meters of nickel iron wire-based Double Loop Wire Ties for rebar mesh, reducing overall installation labor by 17% (client feedback, construction audit report).

Application Case Studies

- Metro Infrastructure Reinforcement: Double Loop Wire Ties made from nickel iron wire used for tying rebar in high-humidity tunnel construction; passed ISO 6892 tensile and ISO 9227 salt spray testing.

- Oil & Gas Plant Safety Mesh: Galvanized iron barbed wire and pure iron wire mesh systems for perimeter security; integrated with smart surveillance (See: IFSEC Global).

- Hydroelectric Cabling Protection: Insulated iron wire ensures cable integrity within flood-prone reservoirs; 20% reduction in failure rate vs standard wires (internal QA report).

- Urban Landscaping: Soft iron wire and wrought iron wire utilized for flexible plant support in municipal gardens; customized color PVC available for client branding.

- Logistics & Packaging: Automatic baling machines equipped with double loop wire ties—productivity rose by 21% (statistically validated by client).

All project deployments strictly adhere to regional and international construction, safety, and materials standards (EN 1992-1-1, ASTM A370, ISO 9001).

FAQ: Technical FAQ on Nickel Iron Wire & Double Loop Wire Ties

Q1: What is the main compositional advantage of nickel iron wire over standard iron wire?

Nickel iron wire is composed of 40–49% Ni and the balance Fe, granting it superior corrosion resistance, enhanced thermal stability, and higher electrical conductivity—ideal for demanding electromagnet and energy sector uses.

Q2: What size/dimensions are available for Double Loop Wire Ties?

Standard diameters are 0.8–2.3mm, with lengths from 100mm to 600mm. Custom sizing, cross-sections (round, flat, PVC-coated), and eyelet diameters can be tailored on request.

Q3: How does "electro galvanized iron wire" compare to "black iron wire" in terms of corrosion and lifespan?

Electro galvanized iron wire is coated with a thin, uniform zinc layer via electroplating, vastly outperforming black iron wire (which only has an oxide film) in humid or outdoor environments. Lifespan is 2–4 times longer in salt-fog tests (ASTM B117).

Q4: Are these wire ties compatible with automated installation tools?

Yes; double loop wire ties and variants are manufactured to consistent tolerances, ensuring reliable performance with pneumatic or electric tie tools for maximum job site productivity.

Q5: What standards and certifications ensure product reliability?

All core products comply with ISO 9001:2015 (Quality Management), EN 10244 (galvanized coating), ASTM A370 (tensile testing), and RoHS/EU REACH (environmental directives).

Q6: How can I specify a custom binding wire for my project?

Share your spec: required tensile strength, diameter range, corrosion resistance (tropic/saline/heavy-duty), color coding, and packaging preference. Manufacturers like CNTC Metal deliver rapid prototyping with supporting certs.

Q7: What's the expected delivery time and warranty for orders above 10,000 units?

Usually 7–15 working days for standard specs. All standard wire ties come with a 1–3 year warranty against manufacturing defects, plus lifetime tech support.

Still have questions? Contact our technical team for tailored engineering solutions or compliance documentation.

Delivery & Support Assurance

- Delivery Time: 7–15 days for typical orders; 15–30 days for large-quantity or fully-custom specifications; global express or sea-freight available.

- Warranty & Quality: All products are subject to batch-wise tensile, elongation and salt-fog testing. Warranty covers manufacturing defects for 1–3 years based on product grade.

- After-sales Service: 24/7 technical support; on-site troubleshooting assistance for key account projects.

- Compliance & Documentation: Full test reports (ISO, ASTM), material certificates, and MSDS shipped with every order.

- Reference Clients: Major MNCs in petrochemical, infrastructure, mining, and logistics sectors; repeated annual contracts demonstrate trust and satisfaction.

References & Industry Knowledge

- [1] Wire Market Insights 2024—Global Nickel and Iron Alloy Wire Industry Analysis (MarketResearchFuture).

- Discussion: Real-World Application of Nickel Iron Wire in Power Systems (Copper Development Association).

- Product Testing and Standards Exchange, Barbed/Galvanized Binding Wire (Engineering Forums).

- Journal: “Performance Characteristics of Nickel Iron Wire in Engineering Structures,” Metal Progress, 2021. (Materials Today Proceedings)

- Technical Product Data: Double Loop Wire Ties - CNTC Metal

share:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025