- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

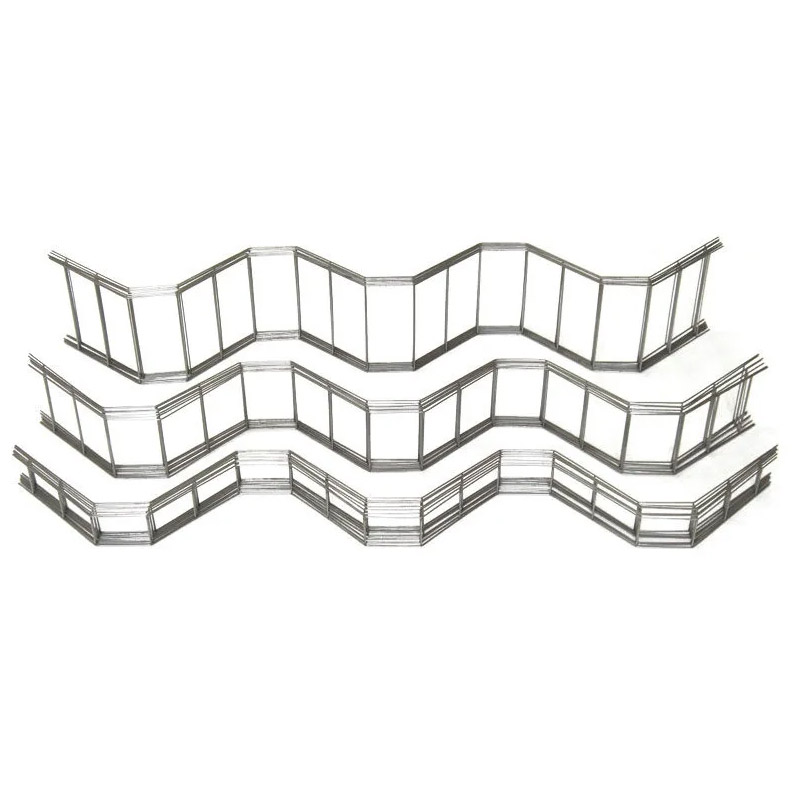

High-Quality Stainless Steel Coil Springs for Durable and Reliable Performance Across Various Applications

The Versatility of Stainless Steel Coil Springs

Stainless steel coil springs are essential components in a wide array of applications across various industries, known for their durability, corrosion resistance, and flexibility. These springs are designed to store energy and absorb shock, playing a pivotal role in the proper functioning of machinery and equipment.

Composition and Properties

Stainless steel is an alloy primarily composed of iron, carbon, and chromium, which gives it exceptional resistance to rust and corrosion. The presence of chromium forms a passive layer of oxide on the surface, protecting the steel beneath. This makes stainless steel coil springs ideal for use in environments that may be exposed to moisture, chemicals, or extreme temperatures.

One of the primary attributes of stainless steel coil springs is their capability to maintain operational integrity and physical characteristics under stress. Unlike conventional steel springs, which may weaken over time due to corrosion, stainless steel coil springs can sustain their performance in demanding conditions, thereby extending their lifespan and reducing maintenance costs.

Applications Across Industries

Stainless steel coil springs are used in a multitude of applications, from automotive and aerospace industries to medical devices and consumer products

.1. Automotive In the automotive sector, these springs are crucial for shock absorption in suspensions, helping to ensure a smooth ride by minimizing the impact of bumps and uneven surfaces. Their strength and resistance to fatigue make them ideal for applications where safety and performance are paramount.

stainless steel coil springs

2. Aerospace In the aerospace industry, weight reduction is critical without compromising strength or reliability. Stainless steel coil springs are often found in aircraft components, where they serve various functions, including gear systems and control surfaces, where precision and durability are essential.

3. Medical Devices The medical field also extensively uses stainless steel coil springs in devices such as surgical instruments and patient monitoring equipment. The materials’ biocompatibility and resistance to sterilization processes make them a top choice for applications requiring cleanliness and hygiene.

4. Consumer Products Everyday items, from appliances to furniture and fitness equipment, also incorporate stainless steel coil springs. Their ability to provide resilience and flexibility in products enhances user experience by improving functionality and comfort.

Manufacturing Process

The manufacturing of stainless steel coil springs typically involves several steps. First, high-grade stainless steel wire is carefully selected based on the specific requirements of the application. The wire undergoes a process of coiling, where it is wound into a spiral shape. Once shaped, the coils are heat-treated to enhance their tensile strength and elasticity.

After heat treatment, springs are often subjected to surface finishing processes to remove any burrs or imperfections, making them smoother and more reliable. Quality control is critical in ensuring that the springs meet industrial standards and specifications.

Conclusion

In conclusion, stainless steel coil springs represent a blend of versatility, durability, and safety, making them an invaluable resource in various industries. Their ability to withstand harsh environments and maintain structural integrity over time positions them as a preferred choice among engineers and manufacturers. As technology advances, the demand for innovative applications of stainless steel coil springs will likely continue to grow, underscoring their importance in modern engineering solutions. The future holds exciting potential for these indispensable components, solidifying their role in shaping the machinery and technologies of tomorrow.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025