- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

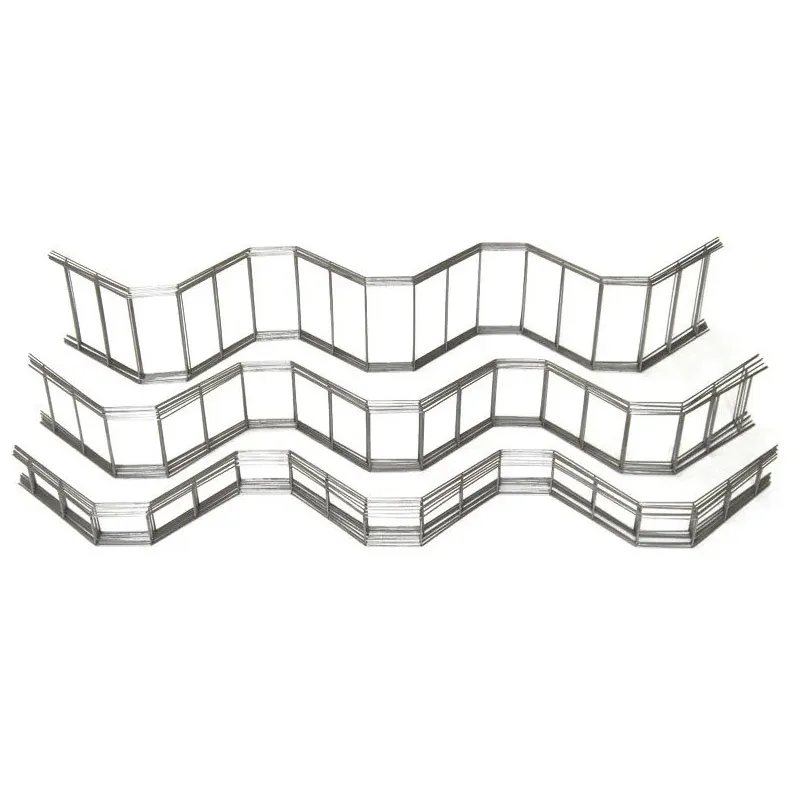

hd compression spring

HD Compression Spring Revolutionizing Industrial Applications

In today's increasingly competitive industrial landscape, the need for efficient and reliable mechanisms in engineering design has never been more vital. One essential element that has seen significant advancements in both design and application is the HD (High-Density) compression spring. This article delves into the fundamentals of HD compression springs, their benefits, applications, and future prospects.

What is an HD Compression Spring?

HD compression springs are tightly coiled cylindrical springs designed to absorb and store energy. They are made from high-strength materials that enable them to withstand significant loads without permanent deformation. The HD aspect refers to their high-density construction, which allows these springs to be both compact and powerful. Unlike standard compression springs, HD compression springs offer improved performance characteristics, such as higher load-bearing capabilities and enhanced durability.

Benefits of HD Compression Springs

The adoption of HD compression springs brings a host of benefits to various industrial sectors. Some of the key advantages include

1. Increased Load Capacity HD compression springs are designed to handle greater loads compared to standard springs. This makes them suitable for heavy-duty applications where traditional springs might fail.

2. Space Efficiency The high-density design allows for a shorter spring length without sacrificing power. This compact nature is particularly advantageous in applications where space is at a premium.

3. Enhanced Durability Made from advanced materials, HD compression springs exhibit superior fatigue resistance and longevity. This means they can operate effectively in demanding environments over extended periods.

4. Improved Performance With a higher spring rate, HD compression springs can offer better energy storage and release capabilities, leading to enhanced overall system performance.

5. Reduced Weight By utilizing high-strength materials, these springs can achieve optimal performance without adding significant weight, making them ideal for aerospace and automotive applications.

Applications of HD Compression Springs

hd compression spring

The versatility of HD compression springs allows them to be employed in various applications across different industries. Some notable applications include

1. Automotive Industry In automotive suspension systems, HD compression springs are used to provide stability and comfort. Their ability to absorb shocks and bumps ensures a smoother ride while maintaining the vehicle's structure.

2. Aerospace Engineering Given their lightweight yet strong properties, HD compression springs are integral in aircraft design. They are utilized in landing gears, control systems, and seats, contributing to overall performance and safety.

3. Manufacturing Machinery Heavy machinery often relies on HD compression springs for various functions, such as in presses and conveyors. They help in maintaining operational efficiency by effectively managing stress and strain.

4. Medical Devices In the medical field, HD compression springs are essential in devices that require precise movement and reliability, such as hospital beds and surgical instruments.

5. Electronics With the increasing miniaturization of electronic devices, HD compression springs find applications in compact electronic assemblies, enhancing their reliability and mechanical stability.

The Future of HD Compression Springs

As industries continue to evolve, the demand for innovative solutions grows. The future for HD compression springs is bright, with advancements in materials science and engineering paving the way for even more robust and efficient designs. Research into new alloys and composite materials could lead to springs that offer superior characteristics, including even higher load capacities and improved fatigue resistance.

Moreover, the integration of smart technologies may allow for real-time monitoring of spring performance, aiding in predictive maintenance and reducing downtime across industries.

Conclusion

HD compression springs are a critical component in modern engineering, offering significant advantages in load capacity, durability, and performance. As industries embrace advanced manufacturing techniques and materials, the importance and relevance of HD compression springs will continue to grow. This innovation not only enhances the functionality of existing systems but also paves the way for future developments in technology and design, making them an indispensable asset in the quest for efficiency and reliability in industrial applications.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025