- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

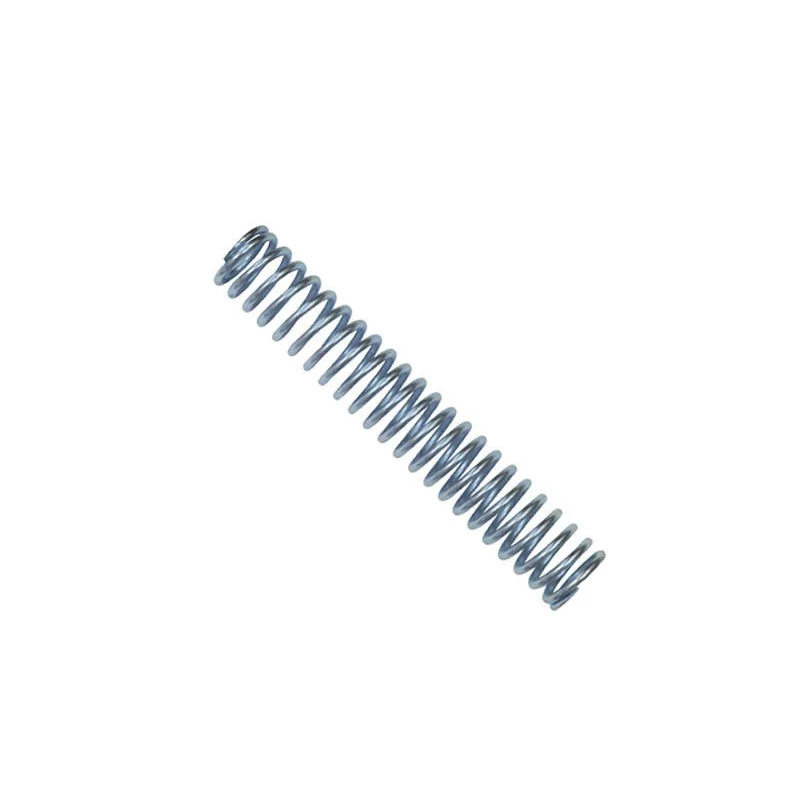

fully compressed spring

Understanding Fully Compressed Springs Mechanics and Applications

Springs are fascinating mechanical components that play vital roles in various applications, from the simple act of closing a pen lid to the complex mechanics of a car suspension system. Among the various types of springs, fully compressed springs are particularly noteworthy for their unique properties and applications.

A spring is typically defined as an elastic device designed to store mechanical energy when compressed, stretched, or twisted. When we refer to a fully compressed spring, we are talking about a spring that has been compressed to its maximum extent, where all the potential energy is stored within its coils and it is at rest in this position. Understanding the mechanics behind fully compressed springs requires an exploration of key concepts such as Hooke's Law, energy storage, and real-world applications.

Hooke’s Law and Energy Storage

At the core of understanding springs is Hooke’s Law, which states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position, given by the formula

\[ F = -kx \]

In this equation, \( F \) represents the force exerted by the spring, \( k \) is the spring constant (which measures the stiffness of the spring), and \( x \) is the displacement from the relaxed position. When a spring is fully compressed, the displacement \( x \) is at its maximum, and the force exerted by the spring is at its highest point in the opposite direction.

The potential energy stored in a compressed spring is given by the formula

fully compressed spring

\[ PE = \frac{1}{2} k x^2 \]

This equation shows that the energy stored increases exponentially as the spring is compressed further

. Thus, a fully compressed spring not only represents a state of maximum displacement but also indicates that it has accumulated significant energy potential, which can be released when the spring is allowed to return to its original shape.Applications of Fully Compressed Springs

Fully compressed springs are crucial in a variety of applications across different industries. In automotive suspensions, for example, these springs absorb shocks and maintain vehicle stability. When the spring is compressed due to the weight of the car, it absorbs energy that would otherwise impact the vehicle's performance and comfort. Once the force is removed, the compressed spring releases its stored energy, restoring the vehicle to its original position and ensuring a smooth ride.

In electronics, fully compressed springs are used in mechanisms such as the push-button switches found in many devices. When pressed, the fully compressed spring activates the switch, allowing it to return to its original state once the pressure is released. The snap-back action ensures a reliable and quick response, showcasing the efficiency of the spring mechanism.

Moreover, in the realm of toys or recreational items, fully compressed springs might be found in devices like dart guns or spring-powered toys, where the spring stores energy until it's suddenly released to propel an object forward. In these cases, the effectiveness and safety of the mechanism heavily depend on how well the spring can be compressed and subsequently released.

Conclusion

Fully compressed springs are more than just mechanical components; they are symbols of energy storage and release, essential for the functionality of numerous devices in everyday life. Their ability to absorb and release energy efficiently makes them indispensable in engineering, automotive design, electronics, and even entertainment. By harnessing the principles established by Hooke’s law, designers and engineers continue to incorporate springs into innovative solutions that enhance performance and user experience. Whether in a simple toy or a complex vehicle suspension system, fully compressed springs remind us of the ingenuity of mechanical engineering and the importance of fundamental principles in practical applications.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025