- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

concrete mesh price

Understanding Concrete Mesh Prices Factors and Insights

Concrete mesh, commonly used in construction for reinforcing concrete structures, plays a crucial role in improving the strength and durability of various projects. As with any building material, the price of concrete mesh can vary significantly based on several factors, and understanding these can help contractors and developers make informed purchasing decisions.

1. Material Composition

Concrete mesh is typically made from steel, though some variations may include alternative materials like fiberglass or polymer composites. The type of steel used—be it carbon steel or stainless steel—affects the price immensely. High-strength steel meshes are generally more expensive due to their enhanced properties and resistance to environmental factors. Additionally, coatings that protect against corrosion can also increase costs.

2. Wire Thickness and Mesh Size

Another significant factor influencing the price of concrete mesh is the thickness of the wires and the size of the mesh openings. Thicker wires provide more strength and support but come at a higher price point. Standard mesh sizes (such as 6x6 or 4x4 inches) are more readily available and often cheaper, while custom sizes designed for specific construction needs can lead to increased costs due to lower production volumes.

3. Type of Weld and Manufacturing Process

The way the concrete mesh is manufactured—whether it is welded wire mesh or woven mesh—also impacts the cost. Welded wire mesh is generally stronger and can be more expensive due to the labor and technology involved in the welding process. The production method and technology used by different manufacturers can also lead to price variations.

concrete mesh price

Like any commodity, the price of concrete mesh is influenced by market demand and supply. In times of increased construction activity, such as during economic booms, demand can drive prices up. Conversely, during economic downturns, a surplus of materials can lead to decreased prices. Seasonal factors can also influence supply; for example, construction activity commonly slows during winter, potentially leading to lower prices.

5. Quantity Purchased

Purchasing concrete mesh in bulk can offer significant cost savings. Many suppliers provide discounts for larger orders, reducing the overall price per unit. It’s essential for buyers to calculate their specific needs accurately to take advantage of bulk pricing without over-purchasing.

6. Transportation and Local Factors

Transportation costs can also add to the overall expense of concrete mesh. Depending on the location of the manufacturer relative to the construction site, delivery fees can vary. Additionally, local competition and market conditions can influence pricing, with some regions experiencing higher costs due to scarcity or increased demand.

Conclusion

Understanding the factors that influence concrete mesh prices can significantly aid in budgeting and planning for construction projects. By considering material composition, wire thickness, manufacturing processes, market dynamics, quantity needs, and local conditions, contractors can make informed decisions. Staying updated on market trends and building relationships with suppliers can also lead to better pricing and sourcing options. In a field where the quality of materials directly impacts the success and safety of a project, careful consideration of concrete mesh purchases is a vital step for any construction professional.

share:

-

Wire Tension Springs for Diverse ApplicationsNewsMay.27,2025

-

Snake SpacersNewsMay.27,2025

-

Sacrificial Formwork Solutions for ConstructionNewsMay.27,2025

-

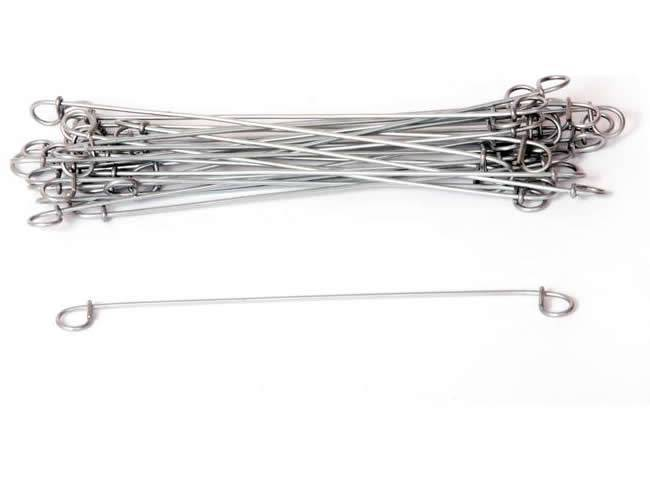

Iron Binding Wire for Your Construction NeedsNewsMay.27,2025

-

Enhance Your Construction Projects with Wire SpacerNewsMay.27,2025

-

Black Annealed Wires for Diverse ApplicationsNewsMay.27,2025

-

Strong Wall Support ChoicesNewsMay.23,2025