- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 14, 2025 06:31

Back to list

wire mesh sheets

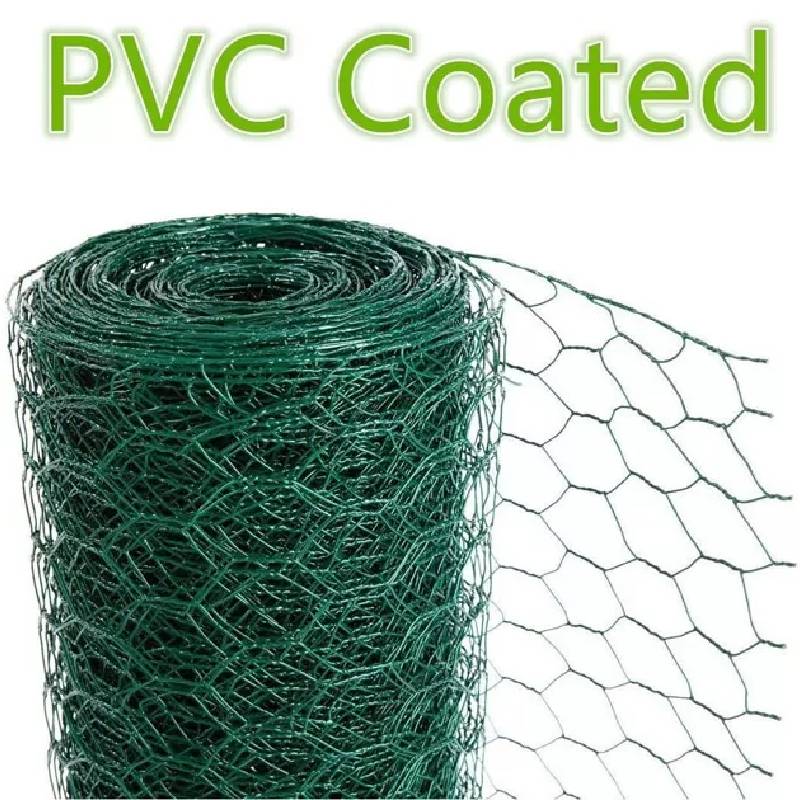

Wire mesh sheets serve as an essential component in various industrial and domestic applications, ranging from construction projects to home improvement tasks. They are renowned for their versatility, durability, and the ability to provide enhanced structural integrity. For those seeking to purchase wire mesh sheets, understanding key aspects can greatly influence their buying decision and ensure optimal results, whether for a major construction project or a small DIY task.

Incorporating wire mesh sheets into a project requires not just an eye for the best deals but also an understanding of how these products fit into and enhance the larger project framework. Buyers should remember that cheaper options may lead to compromised quality, which could undermine the project's success and longevity. For instance, using a lower-quality mesh in a critical load-bearing application could result in structural failure or frequent maintenance issues. For those equipped with adequate knowledge and ready to make a purchase, comparing multiple suppliers both online and offline can lead to discovering more competitive prices and the best-suited products. Platforms offering user reviews and product comparisons can provide valuable insights into past user experiences, further informing your decision-making process. Ultimately, ensuring the quality and compatibility of wire mesh sheets with your project needs an investment of time, research, and often expert consultation. As an integral part of myriad applications, from providing safety and security in windows and doors to strengthening structural elements in construction, wire mesh sheets remain an invaluable resource for many industries. By following these guidelines and prioritizing quality and expert advice, individuals and businesses can procure wire mesh sheets that not only meet their expectations but also exceed the demands of their projects, ensuring durability and efficacy in their application.

Incorporating wire mesh sheets into a project requires not just an eye for the best deals but also an understanding of how these products fit into and enhance the larger project framework. Buyers should remember that cheaper options may lead to compromised quality, which could undermine the project's success and longevity. For instance, using a lower-quality mesh in a critical load-bearing application could result in structural failure or frequent maintenance issues. For those equipped with adequate knowledge and ready to make a purchase, comparing multiple suppliers both online and offline can lead to discovering more competitive prices and the best-suited products. Platforms offering user reviews and product comparisons can provide valuable insights into past user experiences, further informing your decision-making process. Ultimately, ensuring the quality and compatibility of wire mesh sheets with your project needs an investment of time, research, and often expert consultation. As an integral part of myriad applications, from providing safety and security in windows and doors to strengthening structural elements in construction, wire mesh sheets remain an invaluable resource for many industries. By following these guidelines and prioritizing quality and expert advice, individuals and businesses can procure wire mesh sheets that not only meet their expectations but also exceed the demands of their projects, ensuring durability and efficacy in their application.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025