- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 25, 2025 06:11

Back to list

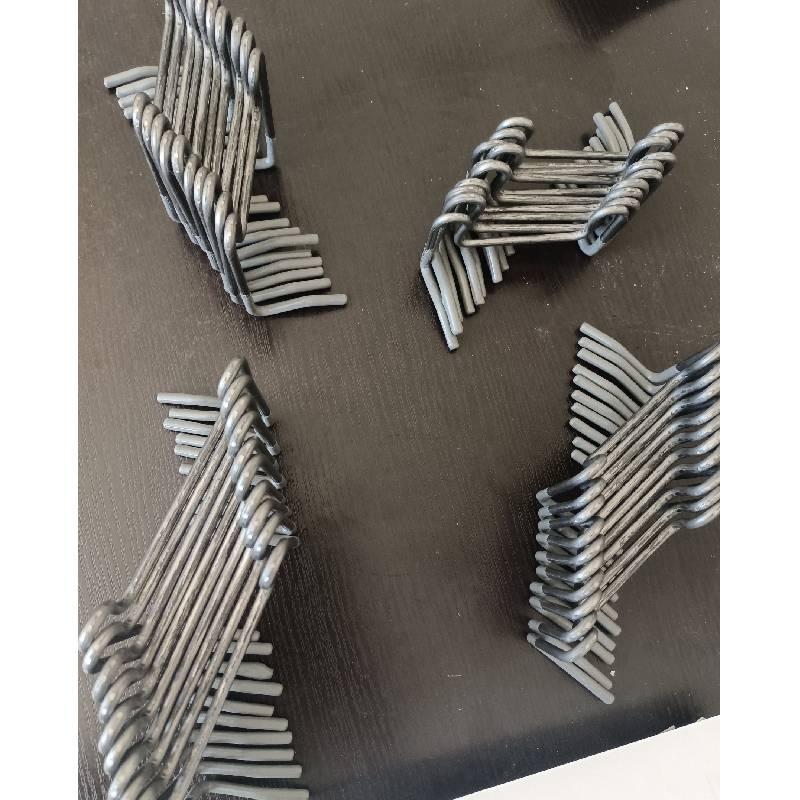

Dowel Cradle baskets

Understanding the pricing dynamics of wire mesh products can be an intricate journey due to the myriad factors influencing the market. As someone with extensive experience in the construction and materials industry, it's crucial to delve into the specifics that impact the cost variations in wire mesh products, aiming to provide invaluable insights for both consumers and suppliers.

Furthermore, environmental regulations and sustainability practices have increasingly influenced wire mesh prices. Manufacturers adhering to green manufacturing practices or producing wire mesh from recycled materials may incur additional costs, these being passed on to consumers. However, consumers might benefit from long-term cost savings and enhanced corporate reputation by investing in sustainable options. When evaluating wire mesh prices for a project, it is imperative to conduct thorough market research, comparing prices from reputable suppliers who are transparent about the factors affecting their pricing structure. This practice ensures not just cost-effectiveness but also incorporates elements of trust and reliability in your supply chain. Moreover, understanding local market peculiarities, such as the prevalence of specific wire mesh standards or regional building codes, can aid in making informed purchasing decisions. Consulting with experts or seasoned professionals in the industry can also provide insights into future market trends and potential price changes, thereby fostering more strategic purchasing decisions. Another viable strategy is leveraging bulk purchasing or long-term contracts with suppliers, which can offer financial benefits and pricing stability. These agreements can safeguard against sudden price hikes and ensure a consistent supply, which is particularly critical for large-scale or long-term projects. In summary, the price of wire mesh is a reflection of multiple intersecting factors ranging from raw materials, industrial processes, market demand, and external economic influences. Expertise in this domain entails navigating these variables with astuteness, ensuring that purchasing decisions are informed by both current supply chain dynamics and future market forecasts. Through a deep understanding of these elements, consumers and businesses alike can achieve greater efficiency and cost savings in their procurement of wire mesh products, echoing the core principles of expertise, authority, and trustworthiness.

Furthermore, environmental regulations and sustainability practices have increasingly influenced wire mesh prices. Manufacturers adhering to green manufacturing practices or producing wire mesh from recycled materials may incur additional costs, these being passed on to consumers. However, consumers might benefit from long-term cost savings and enhanced corporate reputation by investing in sustainable options. When evaluating wire mesh prices for a project, it is imperative to conduct thorough market research, comparing prices from reputable suppliers who are transparent about the factors affecting their pricing structure. This practice ensures not just cost-effectiveness but also incorporates elements of trust and reliability in your supply chain. Moreover, understanding local market peculiarities, such as the prevalence of specific wire mesh standards or regional building codes, can aid in making informed purchasing decisions. Consulting with experts or seasoned professionals in the industry can also provide insights into future market trends and potential price changes, thereby fostering more strategic purchasing decisions. Another viable strategy is leveraging bulk purchasing or long-term contracts with suppliers, which can offer financial benefits and pricing stability. These agreements can safeguard against sudden price hikes and ensure a consistent supply, which is particularly critical for large-scale or long-term projects. In summary, the price of wire mesh is a reflection of multiple intersecting factors ranging from raw materials, industrial processes, market demand, and external economic influences. Expertise in this domain entails navigating these variables with astuteness, ensuring that purchasing decisions are informed by both current supply chain dynamics and future market forecasts. Through a deep understanding of these elements, consumers and businesses alike can achieve greater efficiency and cost savings in their procurement of wire mesh products, echoing the core principles of expertise, authority, and trustworthiness.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025