- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 12, 2025 21:07

Back to list

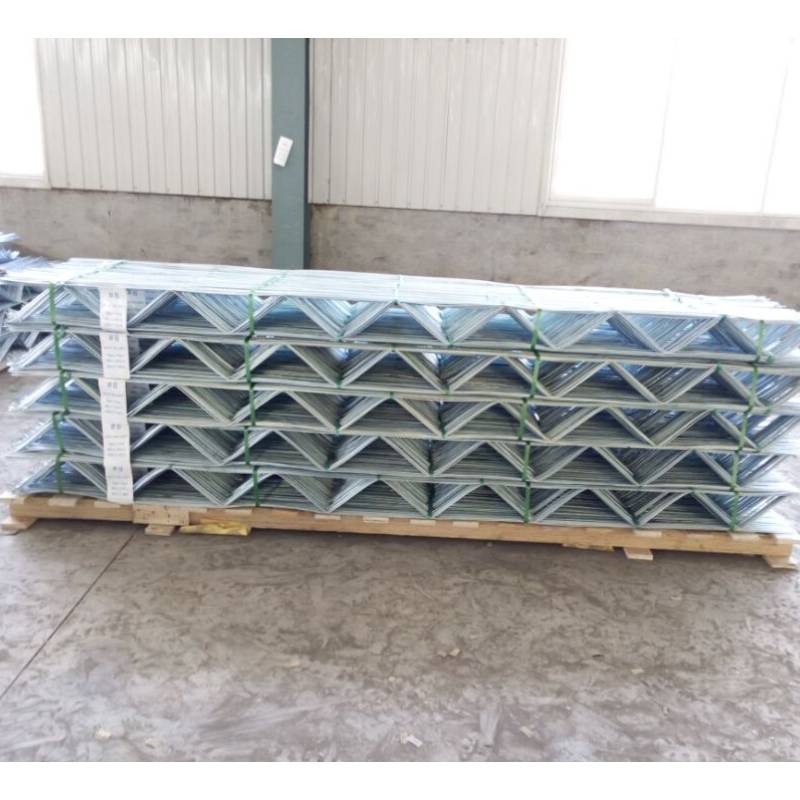

weld mesh sheets prices

Understanding the dynamics of weld mesh sheets prices can vastly enhance decision-making in construction and manufacturing industries. With years of hands-on experience and extensive expertise in the metal mesh industry, navigating the fluctuating prices of weld mesh sheets involves a comprehensive perspective that factors in material quality, global market trends, and supplier reliability.

Furthermore, trustworthiness in this market often correlates with supplier relationships. Long-term contracts with trustworthy suppliers can buffer against sudden price hikes caused by raw material shortages or logistic hurdles. Building and nurturing strong relationships with suppliers can open the way for competitive pricing, flexible terms, and prioritized deliveries - an invaluable advantage in an industry characterized by tight deadlines and thin margins. It is equally prudent for businesses to assess total cost of ownership (TCO) when evaluating weld mesh sheets prices. This approach considers not only the upfront costs but also the longer-term implications such as durability, maintenance expenses, and installation efficiency. A higher initial outlay for better quality sheets might result in lower long-term costs by minimizing replacement or repair needs. Navigating weld mesh sheets prices doesn't end at understanding material and market dynamics. Successful price negotiation requires analytical prowess in cost-benefit assessments and an unwavering commitment to understanding industry trends. Leveraging digital tools for market analysis and enhancing predictive capabilities can also offer substantial advantages in maintaining cost efficiency. In conclusion, a strategic approach to understanding weld mesh sheets prices combines in-depth expertise, supplier relationships, adherence to quality standards, and market knowledge. Staying informed about technological and economic trends while fostering robust supplier relationships can empower businesses to make informed and cost-effective decisions. Sellers, buyers, and stakeholders must engage continuously in knowledge sharing and networking, upholding the tenets of trustworthiness and authority to thrive in this dynamic industry.

Furthermore, trustworthiness in this market often correlates with supplier relationships. Long-term contracts with trustworthy suppliers can buffer against sudden price hikes caused by raw material shortages or logistic hurdles. Building and nurturing strong relationships with suppliers can open the way for competitive pricing, flexible terms, and prioritized deliveries - an invaluable advantage in an industry characterized by tight deadlines and thin margins. It is equally prudent for businesses to assess total cost of ownership (TCO) when evaluating weld mesh sheets prices. This approach considers not only the upfront costs but also the longer-term implications such as durability, maintenance expenses, and installation efficiency. A higher initial outlay for better quality sheets might result in lower long-term costs by minimizing replacement or repair needs. Navigating weld mesh sheets prices doesn't end at understanding material and market dynamics. Successful price negotiation requires analytical prowess in cost-benefit assessments and an unwavering commitment to understanding industry trends. Leveraging digital tools for market analysis and enhancing predictive capabilities can also offer substantial advantages in maintaining cost efficiency. In conclusion, a strategic approach to understanding weld mesh sheets prices combines in-depth expertise, supplier relationships, adherence to quality standards, and market knowledge. Staying informed about technological and economic trends while fostering robust supplier relationships can empower businesses to make informed and cost-effective decisions. Sellers, buyers, and stakeholders must engage continuously in knowledge sharing and networking, upholding the tenets of trustworthiness and authority to thrive in this dynamic industry.

share:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025