- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 10, 2025 20:09

Back to list

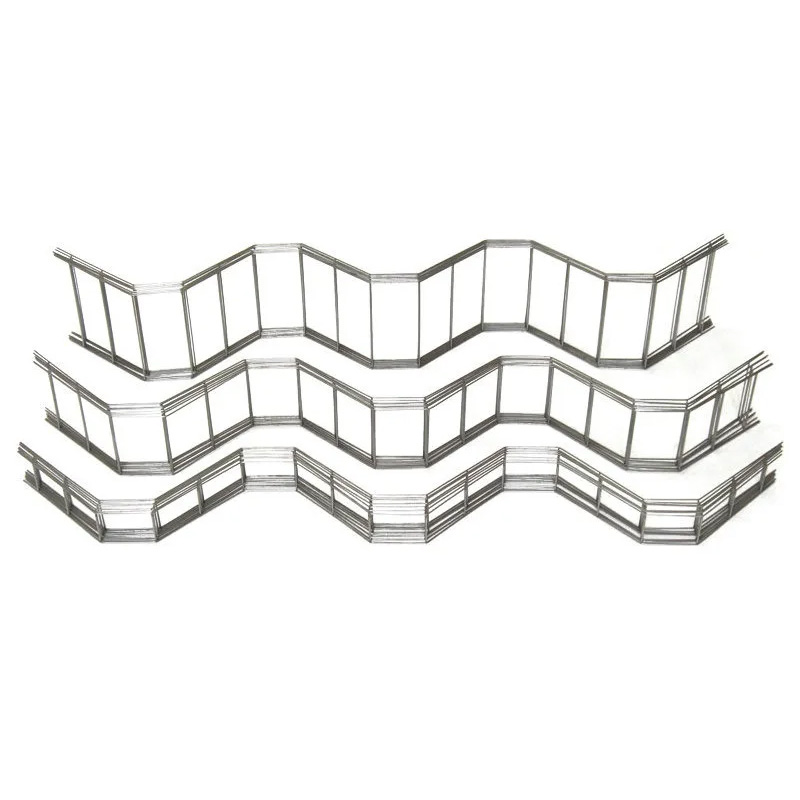

Welded wire mesh

The welded wire mesh material has emerged as a critical component in various industries due to its versatility and strength. This article explores the material's unique qualities, its applications, and why it stands out in the competitive world of construction and industrial usage.

The versatility of welded wire mesh material is another factor contributing to its popularity. In the construction industry, it serves as reinforcement in concrete structures, enhancing their strength and durability. It's also used in making security cages, shelving, partitions, and as a protective measure against intrusion. Beyond construction, welded wire mesh finds applications in agriculture as trellises, in the automotive industry for manufacturing grills, and even in art installations, showcasing its adaptability. Despite its many advantages, selecting the appropriate type of welded wire mesh requires a thorough understanding of the specific project needs. Factors such as environmental conditions, load demands, and budget constraints must be considered. Consulting with experts who understand the material's intricacies ensures the right choice, maximizing both performance and cost-efficiency. Industry standards like ASTM or ISO guidelines provide a benchmark for quality, and sourcing welded wire mesh from a reputable manufacturer guarantees adherence to these standards. This attention to quality and compliance is essential, as the reliability of the structure or product using the mesh hinges on material integrity. In conclusion, welded wire mesh material continues to be a cornerstone in several industries due to its strength, versatility, and ease of use. Its adoption in various applications speaks to its effectiveness and reliability. As innovation drives further enhancements in manufacturing technology, the future promises even more advanced versions of welded wire mesh, expanding its potential uses and solidifying its role as a fundamental material in modern engineering and construction.

The versatility of welded wire mesh material is another factor contributing to its popularity. In the construction industry, it serves as reinforcement in concrete structures, enhancing their strength and durability. It's also used in making security cages, shelving, partitions, and as a protective measure against intrusion. Beyond construction, welded wire mesh finds applications in agriculture as trellises, in the automotive industry for manufacturing grills, and even in art installations, showcasing its adaptability. Despite its many advantages, selecting the appropriate type of welded wire mesh requires a thorough understanding of the specific project needs. Factors such as environmental conditions, load demands, and budget constraints must be considered. Consulting with experts who understand the material's intricacies ensures the right choice, maximizing both performance and cost-efficiency. Industry standards like ASTM or ISO guidelines provide a benchmark for quality, and sourcing welded wire mesh from a reputable manufacturer guarantees adherence to these standards. This attention to quality and compliance is essential, as the reliability of the structure or product using the mesh hinges on material integrity. In conclusion, welded wire mesh material continues to be a cornerstone in several industries due to its strength, versatility, and ease of use. Its adoption in various applications speaks to its effectiveness and reliability. As innovation drives further enhancements in manufacturing technology, the future promises even more advanced versions of welded wire mesh, expanding its potential uses and solidifying its role as a fundamental material in modern engineering and construction.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025