- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 13, 2025 08:56

Back to list

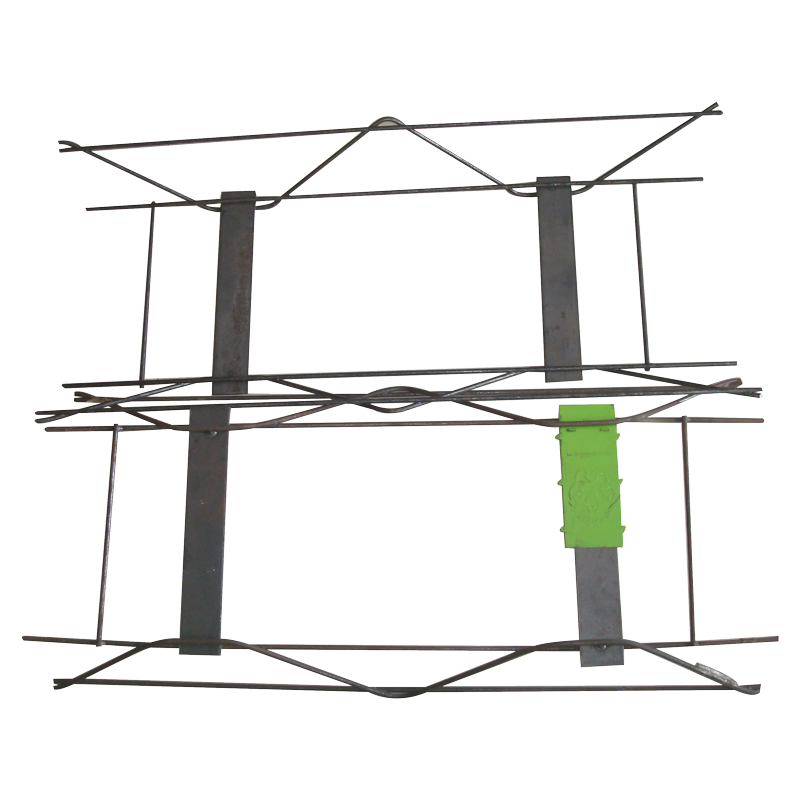

welded wire mesh for concrete slabs specifications

The importance of selecting the right welded wire mesh specifications for concrete slabs cannot be overstated. As a seasoned expert in construction materials, I have come across various key considerations that ensure both structural integrity and durability when applying welded wire mesh (WWM) in concrete slabs.

When evaluating wire mesh for concrete slab projects, compliance with existing standards such as ASTM A1064 in the United States is crucial. These set forth the specific requirements for wire diameter, tensile strength, and overall fabrication quality. Adherence to these standards ensures that the selected mesh will meet the minimum safety and performance criteria, providing long-lasting durability. In terms of sustainability, opting for wire mesh that is made from recycled materials can significantly reduce the environmental impact of construction projects. Many manufacturers now offer high-quality recycled mesh that performs comparably to virgin materials, contributing to overall project sustainability efforts. Experts increasingly emphasize the importance of customization in wire mesh applications. Project-specific requirements, such as unusual slab shapes or load distribution patterns, can be effectively addressed by custom-fabricating the mesh to suit particular conditions. Collaborating with manufacturers who offer bespoke solutions ensures the mesh tightly fits the unique specifications of the construction blueprint. Furthermore, welding technique plays a role in the integrity and effectiveness of the mesh. Electric resistance welding, commonly used in producing WWM, ensures strong bonds between wire intersections. It’s essential to verify that the mesh you procure has undergone rigorous welding quality tests to withstand various construction stresses. The decision-making process surrounding the selection of welded wire mesh is grounded in a deep understanding of these specifications, aligned with rigorous testing and standards. Those involved in the procurement and implementation of wire mesh for concrete slabs must employ a comprehensive analysis of these factors to enhance both the functional and structural outcomes of their projects. Combining expertise and a proven methodology will lead to slabs that not only meet but exceed performance expectations, ensuring longevity and resilience in various construction environments.

When evaluating wire mesh for concrete slab projects, compliance with existing standards such as ASTM A1064 in the United States is crucial. These set forth the specific requirements for wire diameter, tensile strength, and overall fabrication quality. Adherence to these standards ensures that the selected mesh will meet the minimum safety and performance criteria, providing long-lasting durability. In terms of sustainability, opting for wire mesh that is made from recycled materials can significantly reduce the environmental impact of construction projects. Many manufacturers now offer high-quality recycled mesh that performs comparably to virgin materials, contributing to overall project sustainability efforts. Experts increasingly emphasize the importance of customization in wire mesh applications. Project-specific requirements, such as unusual slab shapes or load distribution patterns, can be effectively addressed by custom-fabricating the mesh to suit particular conditions. Collaborating with manufacturers who offer bespoke solutions ensures the mesh tightly fits the unique specifications of the construction blueprint. Furthermore, welding technique plays a role in the integrity and effectiveness of the mesh. Electric resistance welding, commonly used in producing WWM, ensures strong bonds between wire intersections. It’s essential to verify that the mesh you procure has undergone rigorous welding quality tests to withstand various construction stresses. The decision-making process surrounding the selection of welded wire mesh is grounded in a deep understanding of these specifications, aligned with rigorous testing and standards. Those involved in the procurement and implementation of wire mesh for concrete slabs must employ a comprehensive analysis of these factors to enhance both the functional and structural outcomes of their projects. Combining expertise and a proven methodology will lead to slabs that not only meet but exceed performance expectations, ensuring longevity and resilience in various construction environments.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025