- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Mechanics and Applications of V-Shaped Torsion Springs in Engineering

Understanding V-Shaped Torsion Springs A Comprehensive Guide

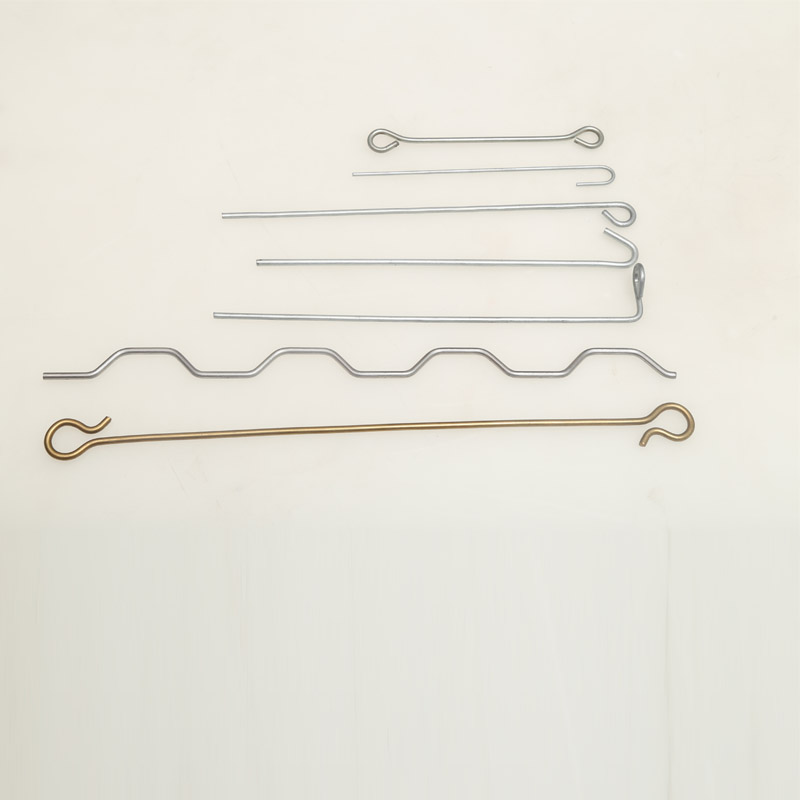

Torsion springs are essential components used in various mechanical applications, providing a rotational force or torque when twisted. Among the various forms of torsion springs, the V-shaped torsion spring stands out due to its unique design and versatile applications. This article delves into the characteristics, manufacturing process, applications, and benefits of V-shaped torsion springs.

What is a V-Shaped Torsion Spring?

V-shaped torsion springs are a specific variant of torsion springs that are shaped like the letter V. This design allows the spring to store and release energy efficiently when subjected to angular deflection. Unlike conventional torsion springs, which are typically wound into helical forms, V-shaped torsion springs have two arms that assume a V configuration. This shape allows for a larger surface area in contact with the mechanisms they interact with, resulting in enhanced stability and functionality.

Characteristics of V-Shaped Torsion Springs

1. Design Flexibility V-shaped torsion springs can be customized in terms of size, material, and tension levels to meet specific operational requirements. The angle of the V and the length of the arms can also be modified to suit various applications.

2. Material Options Typically, these springs are made from high-carbon steel, stainless steel, or other alloys, ensuring durability and resistance to deformation under heavy loads. The choice of material plays a crucial role in determining the spring's performance and lifespan.

3. Mechanical Advantage The V shape enhances the mechanical advantage of the spring by allowing it to exert force over a larger radius, making it suitable for applications requiring significant torque without consuming excessive space.

4. Efficiency The design of V-shaped torsion springs often results in low friction between moving parts, increasing overall energy efficiency in mechanical systems.

Manufacturing Process

The manufacturing of V-shaped torsion springs involves several critical steps

1. Material Selection Choosing the appropriate raw material is crucial for achieving the desired mechanical properties and resistance to fatigue.

2. Cutting and Shaping The metal is cut into the required lengths before it undergoes shaping. This step may involve bending the metal to form the V structure accurately.

3. Winding The arms of the spring are then twisted to achieve the necessary tension and torque specifications. This process requires precision to ensure that the spring will perform as expected under load.

4. Heat Treatment Many V-shaped torsion springs undergo heat treatment to enhance their strength and elasticity. This step is vital for improving the spring’s fatigue life and overall reliability.

v shaped torsion springs

5. Quality Control After manufacturing, the springs are subjected to rigorous testing to ensure they meet design specifications and performance standards.

Applications of V-Shaped Torsion Springs

V-shaped torsion springs are utilized in a myriad of applications across different industries

- Automotive Industry These springs are commonly found in vehicle door hinges, providing the necessary resistance and facilitating smooth opening and closing.

- Electronics In consumer electronics, V-shaped torsion springs are employed in devices such as laptops and mobile phones for their hinges, ensuring durability while maintaining compactness.

- Industrial Equipment They are often used in machinery where adjustable torque is required, such as in conveyor systems or automated assembly lines.

- Furniture Design V-shaped torsion springs are integral in the mechanism of folding tables and recliners, allowing for effortless adjustments.

Benefits of Using V-Shaped Torsion Springs

The advantages of incorporating V-shaped torsion springs in mechanical designs include

1. Space Efficiency Their unique shape allows for a compact design without sacrificing performance, making them ideal for applications with limited space.

2. Improved Stability The V configuration provides enhanced stability, reducing the risk of misalignment or detachment during operation.

3. Cost-Effectiveness While the initial investment may be higher, the durability and reduced maintenance needs can lead to lower overall costs in the long run.

4. Versatility Their adaptability makes V-shaped torsion springs suitable for a wide range of applications, enhancing their appeal across multiple industries.

Conclusion

In summary, V-shaped torsion springs are crucial components in various mechanical systems, providing efficient energy storage and release through a unique design. Their adaptability, durability, and diverse applications make them invaluable in today’s technology-driven world. Understanding their characteristics and benefits will help engineers and designers leverage them effectively in their projects.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025