- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 31, 2025 04:48

Back to list

PVC Coated Welded Mesh

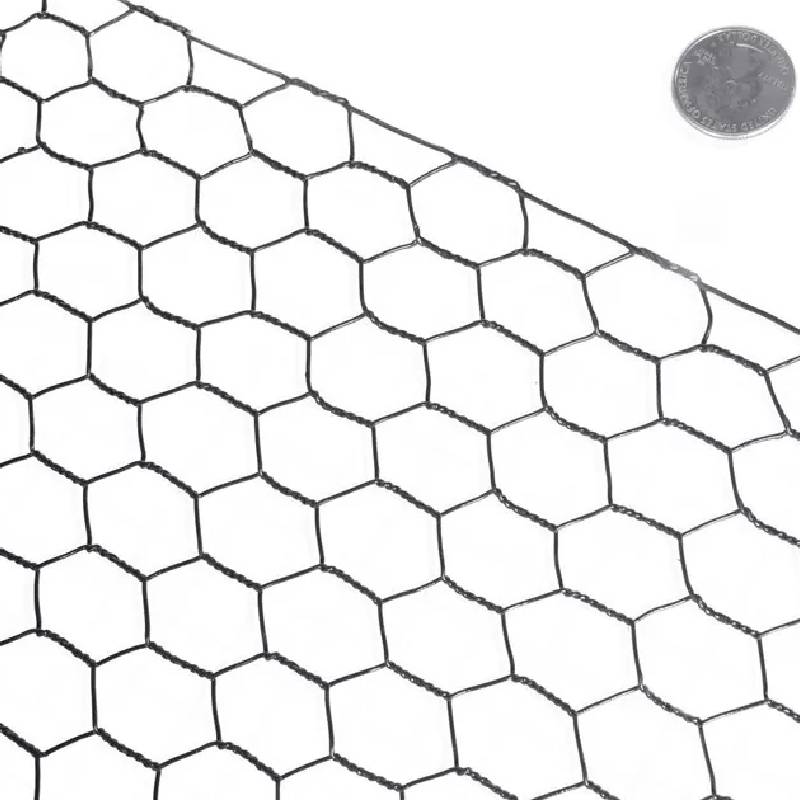

Utilizing chicken mesh in construction has gained notable attention in the industry for its versatility and cost-effectiveness. This lightweight, durable material, commonly known as chicken wire, serves a plethora of functions in building projects, driving innovation and efficiency across various applications. So, what makes chicken mesh a superior choice, and how can it enhance construction projects?

For inexperienced builders or DIY enthusiasts, chicken mesh offers a hassle-free installation process. The simplicity of measuring, cutting, and securing the mesh enables users to adopt it across various small-scale projects without the need for specialized tools or training. It is suitable for securing insulation materials, creating garden boundaries, or crafting lightweight formworks. The versatile application of chicken mesh empowers novice builders to achieve professional-grade results, expanding the possibilities for residential and hobbyist construction projects. Critically, the affordability of chicken mesh is unmatched. Compared to traditional reinforcement materials like steel bars or fiber-reinforced polymers, chicken mesh boasts a competitive price point, making it an attractive option for both large-scale commercial builders and small-time renovators. Its cost-effectiveness does not compromise its quality or performance—testing and manufacturing standards ensure that chicken mesh meets rigorous industry benchmarks for durability and safety. To emphasize the expertise and reliability that chicken mesh brings to construction, many industry experts and manufacturers endorse its use. The simplicity and effectiveness with which chicken mesh can be applied affirm its status as a trusted material among contractors worldwide. Renowned building materials manufacturers have consistently vouched for its reliability, reinforcing its position as a leading choice for modern construction needs. In summary, the use of chicken mesh in construction transcends traditional applications, providing builders with a blend of efficiency, cost-effectiveness, and sustainability. It offers an indispensable tool for diverse construction tasks—from reinforcing clay and plaster to enabling earthquake-resistant designs and supporting eco-friendly construction techniques. As a staple in the builder’s toolkit, chicken mesh represents a confluence of innovation and practicality, enhancing both the structural integrity and economic viability of construction projects. Through careful selection and application, it empowers builders to meet—and exceed—the challenges of modern architecture, delivering outcomes that stand the test of time.

For inexperienced builders or DIY enthusiasts, chicken mesh offers a hassle-free installation process. The simplicity of measuring, cutting, and securing the mesh enables users to adopt it across various small-scale projects without the need for specialized tools or training. It is suitable for securing insulation materials, creating garden boundaries, or crafting lightweight formworks. The versatile application of chicken mesh empowers novice builders to achieve professional-grade results, expanding the possibilities for residential and hobbyist construction projects. Critically, the affordability of chicken mesh is unmatched. Compared to traditional reinforcement materials like steel bars or fiber-reinforced polymers, chicken mesh boasts a competitive price point, making it an attractive option for both large-scale commercial builders and small-time renovators. Its cost-effectiveness does not compromise its quality or performance—testing and manufacturing standards ensure that chicken mesh meets rigorous industry benchmarks for durability and safety. To emphasize the expertise and reliability that chicken mesh brings to construction, many industry experts and manufacturers endorse its use. The simplicity and effectiveness with which chicken mesh can be applied affirm its status as a trusted material among contractors worldwide. Renowned building materials manufacturers have consistently vouched for its reliability, reinforcing its position as a leading choice for modern construction needs. In summary, the use of chicken mesh in construction transcends traditional applications, providing builders with a blend of efficiency, cost-effectiveness, and sustainability. It offers an indispensable tool for diverse construction tasks—from reinforcing clay and plaster to enabling earthquake-resistant designs and supporting eco-friendly construction techniques. As a staple in the builder’s toolkit, chicken mesh represents a confluence of innovation and practicality, enhancing both the structural integrity and economic viability of construction projects. Through careful selection and application, it empowers builders to meet—and exceed—the challenges of modern architecture, delivering outcomes that stand the test of time.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025