- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 15, 2025 01:47

Back to list

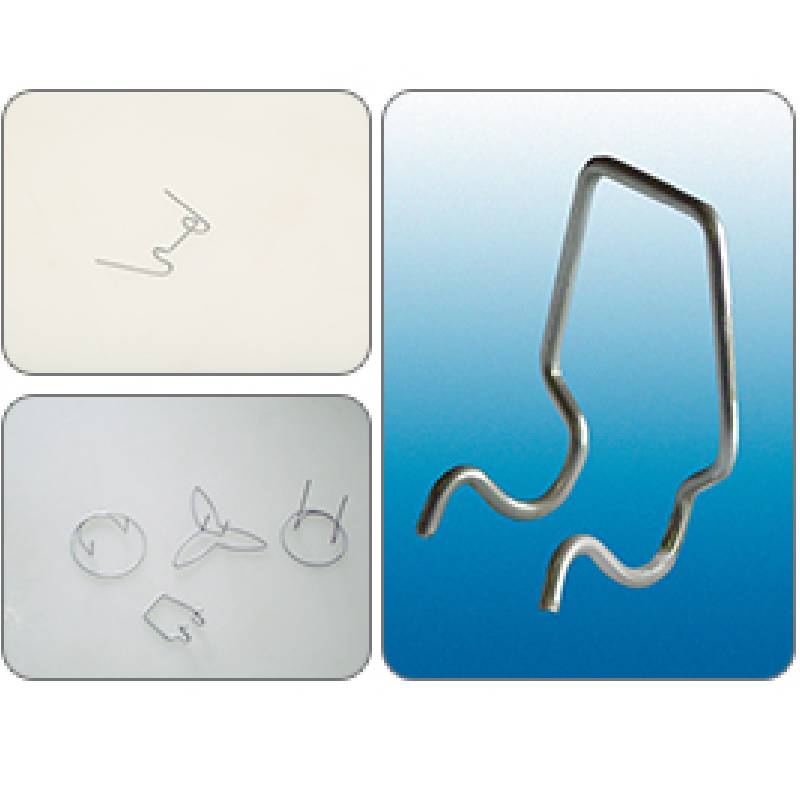

thin iron wire

Thin iron wire is a notable material leveraging its unique properties in various industries. This versatile component streams through multiple applications, signaling its importance in the production landscape. Understanding thin iron wire involves delving into its exhaustive uses, specialized characteristics, and its inherent advantages over other materials.

In a market where reliability is paramount, the authoritativeness of thin iron wire is substantiated by its historical application and trusted performance. For instance, its long-standing presence in the telecommunication industry, where it serves as binding for cables and connectors, highlights its sustained utility and dependability. Technical manuals and industrial standards frequently reference thin iron wire, reinforcing its position as a material of choice for specific applications, and thus solidifying its authoritative status. Building trust in thin iron wire within the consumer domain relies heavily on quality assurance and transparency. Manufacturers ensure that their products meet rigorous standards through certifications and batch testing, promoting consumer confidence. Collaborative feedback from users across different industries also plays an essential role in broadening trust. Users consistently report satisfaction with thin iron wire’s performance, noting its balance of strength and flexibility as key attributes that meet their application needs without premature failure or degradation. In conclusion, thin iron wire emerges as a critical material across various domains, thanks to its adaptable characteristics and impeccable performance. From enhancing structural integrity in construction to adding finesse in artistic creations, its applicability is vast and varied. Professionals and enthusiasts alike turn to thin iron wire as a reliable solution, drawn by its proven track record and continued adaptability to technological advancements and market demands. The insights drawn from extensive use and industry-specific expertise underscore its place as a material that not only meets but exceeds the expectations of reliability and innovation in contemporary applications.

In a market where reliability is paramount, the authoritativeness of thin iron wire is substantiated by its historical application and trusted performance. For instance, its long-standing presence in the telecommunication industry, where it serves as binding for cables and connectors, highlights its sustained utility and dependability. Technical manuals and industrial standards frequently reference thin iron wire, reinforcing its position as a material of choice for specific applications, and thus solidifying its authoritative status. Building trust in thin iron wire within the consumer domain relies heavily on quality assurance and transparency. Manufacturers ensure that their products meet rigorous standards through certifications and batch testing, promoting consumer confidence. Collaborative feedback from users across different industries also plays an essential role in broadening trust. Users consistently report satisfaction with thin iron wire’s performance, noting its balance of strength and flexibility as key attributes that meet their application needs without premature failure or degradation. In conclusion, thin iron wire emerges as a critical material across various domains, thanks to its adaptable characteristics and impeccable performance. From enhancing structural integrity in construction to adding finesse in artistic creations, its applicability is vast and varied. Professionals and enthusiasts alike turn to thin iron wire as a reliable solution, drawn by its proven track record and continued adaptability to technological advancements and market demands. The insights drawn from extensive use and industry-specific expertise underscore its place as a material that not only meets but exceeds the expectations of reliability and innovation in contemporary applications.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025