- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 17, 2025 04:52

Back to list

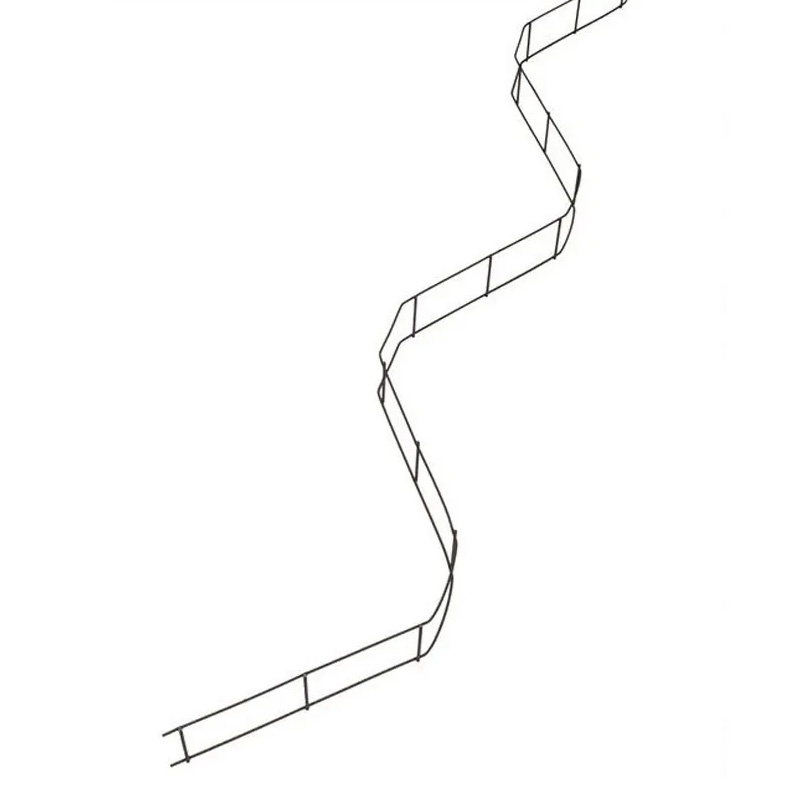

Galvanized iron wire

Galvanized steel wire, renowned for its durability and versatility, plays a pivotal role in a myriad of industries. This essential material, achieved through the process of coating steel wire with a layer of zinc, stands as a testament to both modern engineering and enduring reliability. In industries ranging from construction to agriculture, the adoption of galvanized steel wire is driven by its unique properties and adaptability to diverse needs.

Understanding these elemental processes is part of what makes our team at the forefront of galvanization innovation. With decades of expertise, our approach is guided by rigorous quality control at every stage—from assessing the raw steel for suitability to the precise control of zinc coating thickness. The result is a product that our clients trust implicitly—a statement to our commitment to quality and reliability. Furthermore, environmental stewardship remains a priority in our operations. The galvanization process is optimized to minimize emissions and waste. The sustainability of galvanized steel wire extends beyond its corrosion resistance; it is also recyclable. At the end of its lifecycle, the wire can be repurposed, affirming its role in resource conservation efforts. Our authority in the field is further solidified by accreditations and partnerships with leading engineering bodies. Collaborations with research institutions enable us to remain at the cutting edge of galvanization technology, ensuring our products are not just market-ready but future-ready. This collaboration fuels constant innovation, driving the development of new applications and efficiencies in both production and deployment. Trust is the cornerstone of our operations. Clients frequently note the predictable quality and exceptional service as reasons for continued partnership. We provide not just a product, but a promise of performance. This ethos guides every aspect of our business, whether interfacing with global corporations or individual customers seeking advice on specific applications. Galvanized steel wire symbolizes an intersection of tradition and innovation, embodying qualities that modern industries rely on while continuing to evolve in line with technological advancements. As our expertise, experience, and commitment to quality push forward, so too does the value galvanized steel wire brings to an interconnected world. Embracing this material is more than an operational choice—it's a strategic decision that influences success across countless applications.

Understanding these elemental processes is part of what makes our team at the forefront of galvanization innovation. With decades of expertise, our approach is guided by rigorous quality control at every stage—from assessing the raw steel for suitability to the precise control of zinc coating thickness. The result is a product that our clients trust implicitly—a statement to our commitment to quality and reliability. Furthermore, environmental stewardship remains a priority in our operations. The galvanization process is optimized to minimize emissions and waste. The sustainability of galvanized steel wire extends beyond its corrosion resistance; it is also recyclable. At the end of its lifecycle, the wire can be repurposed, affirming its role in resource conservation efforts. Our authority in the field is further solidified by accreditations and partnerships with leading engineering bodies. Collaborations with research institutions enable us to remain at the cutting edge of galvanization technology, ensuring our products are not just market-ready but future-ready. This collaboration fuels constant innovation, driving the development of new applications and efficiencies in both production and deployment. Trust is the cornerstone of our operations. Clients frequently note the predictable quality and exceptional service as reasons for continued partnership. We provide not just a product, but a promise of performance. This ethos guides every aspect of our business, whether interfacing with global corporations or individual customers seeking advice on specific applications. Galvanized steel wire symbolizes an intersection of tradition and innovation, embodying qualities that modern industries rely on while continuing to evolve in line with technological advancements. As our expertise, experience, and commitment to quality push forward, so too does the value galvanized steel wire brings to an interconnected world. Embracing this material is more than an operational choice—it's a strategic decision that influences success across countless applications.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025