- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 04, 2025 01:38

Back to list

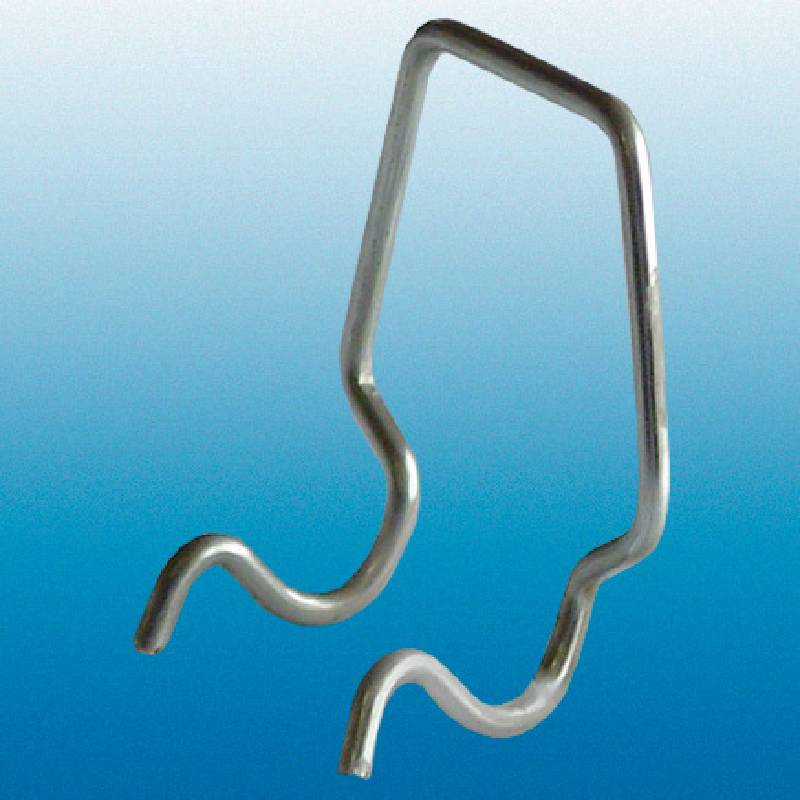

metal mesh concrete reinforcement

The integrity of construction is deeply anchored in its foundations, and metal mesh concrete reinforcement has emerged as an indispensable component for modern-day building projects. Esteemed within the construction industry for its strength and adaptability, metal mesh reinforcement contributes significantly to the durability, safety, and efficiency of concrete structures. This article delves into the intricacies of metal mesh concrete reinforcement, offering insights into its practical applications, benefits, and its crucial role in the construction domain, all backed by decades of industry expertise.

In the realm of sustainability, metal mesh concrete reinforcement also presents considerable benefits. Steel, the primary material used, is recyclable and does not degrade in quality through the recycling process. This recyclability aligns with the growing demand for sustainable construction practices, reducing the environmental footprint of building projects. Additionally, steel reinforced concrete structures have longer lifespans, reducing the need for frequent repairs or replacements which, in turn, conserves resources and energy over time. Furthermore, the use of high-quality standards in the production of metal mesh fortifies its trustworthiness in structural applications. Certifications and compliance with international building codes ensure that the metal mesh meets rigorous safety and durability criteria, boosting confidence among engineers, architects, and end-users. A testament to metal mesh's authority in the construction industry is its role in pioneering architectural designs. Modern architects exploit the flexibility and strength of metal mesh reinforcement to push the boundaries of traditional design, creating innovative structures that blend aesthetics with functionality. From ultra-thin facades to expansive open-plan spaces unsupported by columns, the possibilities opened up by metal mesh are vast and continue to grow. In conclusion, metal mesh concrete reinforcement stands as a pillar of modern construction, merging the artistic vision with engineering precision. It embodies the core values of longevity, strength, and adaptability, all vital for today's construction demands. Whether viewed through the lens of cost-efficiency, environmental responsibility, or architectural creativity, metal mesh is imbued with qualities that make it indispensable for the next generation of builders and architects. As construction challenges grow more complex, the role of metal mesh as a reliable and versatile reinforcement solution is poised to become even more pronounced, embedding itself as a cornerstone in the future of building technology.

In the realm of sustainability, metal mesh concrete reinforcement also presents considerable benefits. Steel, the primary material used, is recyclable and does not degrade in quality through the recycling process. This recyclability aligns with the growing demand for sustainable construction practices, reducing the environmental footprint of building projects. Additionally, steel reinforced concrete structures have longer lifespans, reducing the need for frequent repairs or replacements which, in turn, conserves resources and energy over time. Furthermore, the use of high-quality standards in the production of metal mesh fortifies its trustworthiness in structural applications. Certifications and compliance with international building codes ensure that the metal mesh meets rigorous safety and durability criteria, boosting confidence among engineers, architects, and end-users. A testament to metal mesh's authority in the construction industry is its role in pioneering architectural designs. Modern architects exploit the flexibility and strength of metal mesh reinforcement to push the boundaries of traditional design, creating innovative structures that blend aesthetics with functionality. From ultra-thin facades to expansive open-plan spaces unsupported by columns, the possibilities opened up by metal mesh are vast and continue to grow. In conclusion, metal mesh concrete reinforcement stands as a pillar of modern construction, merging the artistic vision with engineering precision. It embodies the core values of longevity, strength, and adaptability, all vital for today's construction demands. Whether viewed through the lens of cost-efficiency, environmental responsibility, or architectural creativity, metal mesh is imbued with qualities that make it indispensable for the next generation of builders and architects. As construction challenges grow more complex, the role of metal mesh as a reliable and versatile reinforcement solution is poised to become even more pronounced, embedding itself as a cornerstone in the future of building technology.

share:

Next:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025