- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 14, 2025 12:28

Back to list

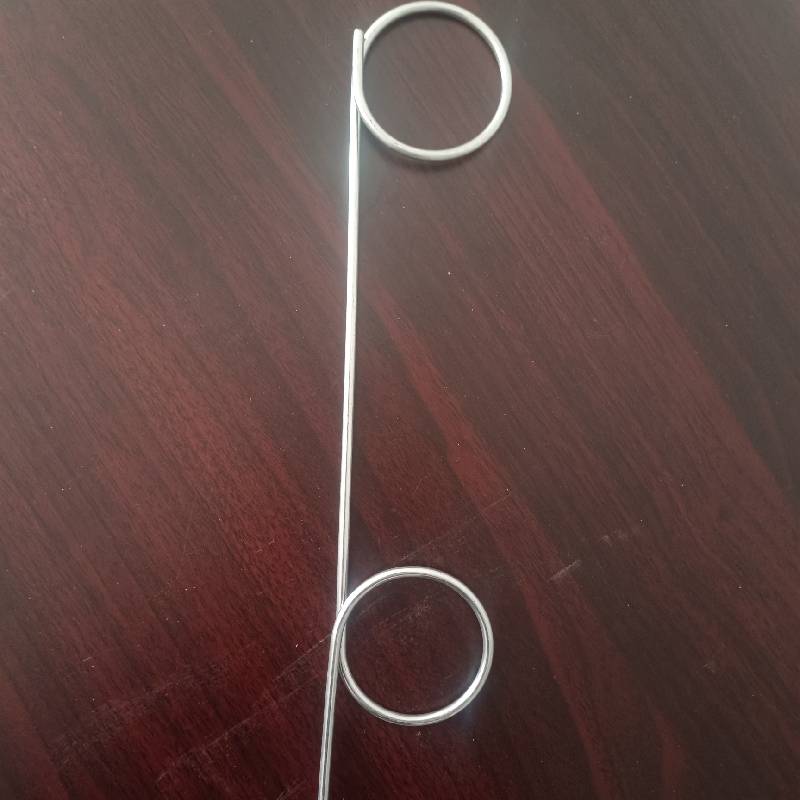

iron binding wire

Iron binding wire, an essential component in both industrial and residential construction, plays a vital role in ensuring the integrity and stability of various structures. Made typically from mild steel and designed for high flexibility and durability, iron binding wire is indispensable for tasks such as securing reinforcing bars, bundling rods, and of course, for general binding purposes across a plethora of projects.

In terms of authoritativeness and trustworthiness, leading construction firms and consultants often collaborate with reputable manufacturers known for their rigorous quality standards. Reliable producers of iron binding wire provide detailed documentation on their products, including tensile strength ratings, elongation percentages, and coating thickness, which are critical for meeting safety standards and project specifications. Engaging with these high-caliber suppliers ensures not only the performance of the material but also provides peace of mind that the wire will uphold its promise under duress. Efficient utilization of iron binding wire can be a game-changer on-site. By ensuring proper storage—where humidity and exposure to direct sunlight are minimized—users can maintain the wire’s quality over prolonged periods. Furthermore, using tools like wire twisters can facilitate the binding process, reducing labor time and improving safety by ensuring the wire is applied with consistent tension. For professionals aiming to reinforce their knowledge and application of binding wire, continuous education on the latest technologies and standards is advisable. Attending industry workshops, engaging with expert discussions, and subscribing to construction journals are all valuable practices to stay at the forefront of innovations within the field. Ultimately, mastering the use of iron binding wire can significantly bolster the success of construction endeavors, ensuring that projects are completed with an unwavering emphasis on durability and safety.

In terms of authoritativeness and trustworthiness, leading construction firms and consultants often collaborate with reputable manufacturers known for their rigorous quality standards. Reliable producers of iron binding wire provide detailed documentation on their products, including tensile strength ratings, elongation percentages, and coating thickness, which are critical for meeting safety standards and project specifications. Engaging with these high-caliber suppliers ensures not only the performance of the material but also provides peace of mind that the wire will uphold its promise under duress. Efficient utilization of iron binding wire can be a game-changer on-site. By ensuring proper storage—where humidity and exposure to direct sunlight are minimized—users can maintain the wire’s quality over prolonged periods. Furthermore, using tools like wire twisters can facilitate the binding process, reducing labor time and improving safety by ensuring the wire is applied with consistent tension. For professionals aiming to reinforce their knowledge and application of binding wire, continuous education on the latest technologies and standards is advisable. Attending industry workshops, engaging with expert discussions, and subscribing to construction journals are all valuable practices to stay at the forefront of innovations within the field. Ultimately, mastering the use of iron binding wire can significantly bolster the success of construction endeavors, ensuring that projects are completed with an unwavering emphasis on durability and safety.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025