- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 16, 2025 05:01

Back to list

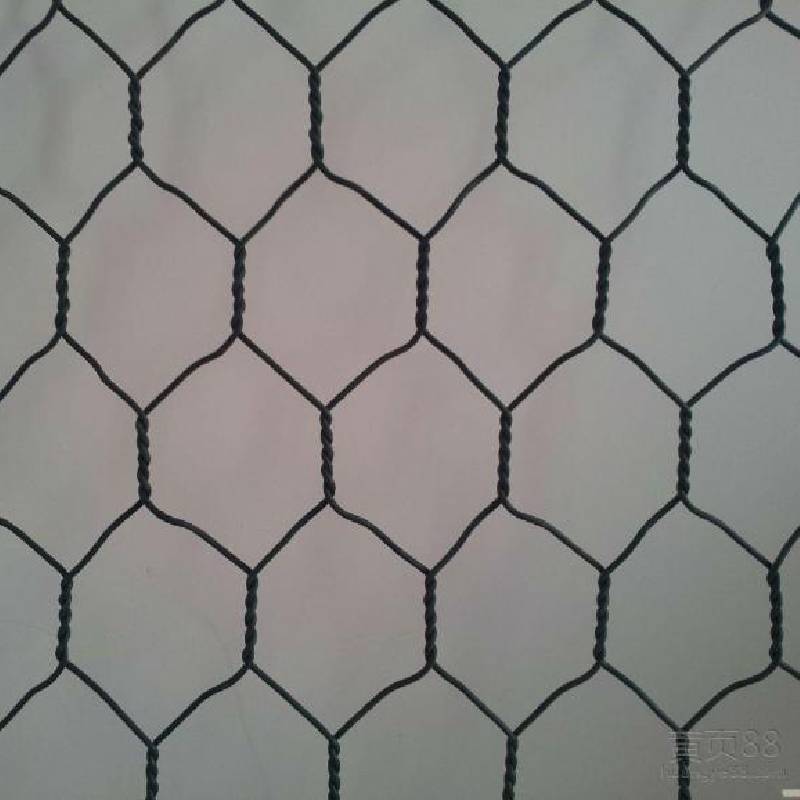

Galvanized iron wire

Hot dipped galvanized wire, a robust and long-lasting product, stands as a crucial component in various industrial and construction applications. Its production involves coating steel wire with a layer of zinc, which offers superior corrosion resistance compared to untreated steel. This process ensures enhanced durability, making it ideal for outdoor uses where exposure to environmental elements is a concern.

One of the most significant innovations in hot dipped galvanized wire is the integration of advanced galvanizing techniques, ensuring better adhesion and a more uniform zinc coating. This advancement has led to improved protection against chipping and peeling, common issues that plagued earlier versions of galvanized products. Consequently, this progress has enhanced the wire’s appeal to sectors requiring high reliability under challenging conditions. The sustainable aspect of hot dipped galvanized wire further underscores its suitability. The zinc coating is entirely recyclable, and the overall product has a longer lifecycle compared to alternatives. This attribute not only reduces the carbon footprint of its applications but also aligns with global sustainability goals by minimizing material wastage. Investing in hot dipped galvanized wire is strategically sound for businesses aiming to uphold both quality and sustainability. With reliable suppliers offering comprehensive quality assurance documentation, customers can confidently integrate this material into their projects, knowing they are supported by a robust supply chain and expert advice. Such trust-based relationships are paramount in large-scale projects where timely delivery and product integrity are non-negotiable. In summary, hot dipped galvanized wire is a testament to enduring engineering solutions, combining traditional metallurgical practices with modern innovations to meet contemporary demands. Its unmatched resilience, backed by authoritative standards and extensive usage experiences, affords it a place of high trust and reliability within numerous industries. This makes it an irreplaceable asset in both current applications and future infrastructure developments.

One of the most significant innovations in hot dipped galvanized wire is the integration of advanced galvanizing techniques, ensuring better adhesion and a more uniform zinc coating. This advancement has led to improved protection against chipping and peeling, common issues that plagued earlier versions of galvanized products. Consequently, this progress has enhanced the wire’s appeal to sectors requiring high reliability under challenging conditions. The sustainable aspect of hot dipped galvanized wire further underscores its suitability. The zinc coating is entirely recyclable, and the overall product has a longer lifecycle compared to alternatives. This attribute not only reduces the carbon footprint of its applications but also aligns with global sustainability goals by minimizing material wastage. Investing in hot dipped galvanized wire is strategically sound for businesses aiming to uphold both quality and sustainability. With reliable suppliers offering comprehensive quality assurance documentation, customers can confidently integrate this material into their projects, knowing they are supported by a robust supply chain and expert advice. Such trust-based relationships are paramount in large-scale projects where timely delivery and product integrity are non-negotiable. In summary, hot dipped galvanized wire is a testament to enduring engineering solutions, combining traditional metallurgical practices with modern innovations to meet contemporary demands. Its unmatched resilience, backed by authoritative standards and extensive usage experiences, affords it a place of high trust and reliability within numerous industries. This makes it an irreplaceable asset in both current applications and future infrastructure developments.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025