- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 17, 2025 02:12

Back to list

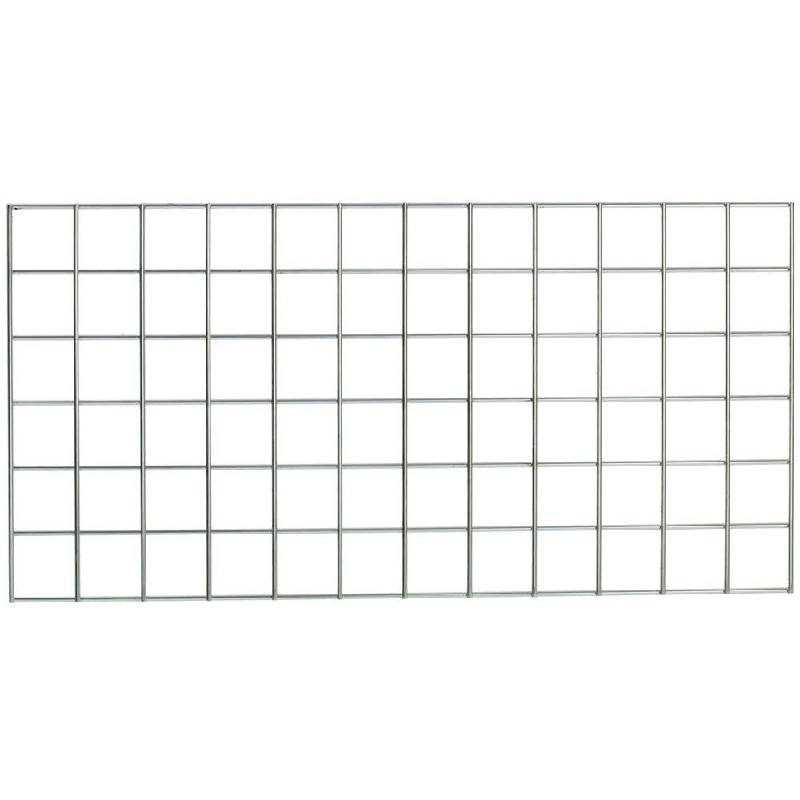

gi tie wire

Galvanized iron tie wire has long stood as an indispensable material in various industries due to its durability and versatility. It is essential for construction, agricultural, and industrial applications, serving as a binding solution that ensures safety and stability in numerous projects. Users from all these sectors recognize it for its ease of use and reliability.

Among the key attributes that elevate one brand’s product over another is the wire’s tensile strength. A higher tensile strength indicates that the wire can handle significant stress without snapping, which is vital in applications that demand stability. Professionals in the field value this characteristic, as it often differentiates a top-tier product from its competitors. It's crucial for companies selling these wires to establish authority by providing detailed technical specifications and usage guidelines. Through authoritative content and demonstrative videos, businesses can build trust with their customers. This approach not only highlights the brand’s expertise but also aids users in making informed purchasing decisions based on their specific needs. Renowned brands usually offer insights into optimal storage solutions to prevent any potential degradation of the wire’s protective zinc layer. Recommendations often include storing the wire in cool, dry environments away from direct sunlight and other potential sources of chemical exposure. Such authoritative advice enhances a customer’s trust, reinforcing the brand's credibility. Ultimately, the trustworthiness of a company offering galvanized iron tie wire is often reflected in customer reviews and industry certifications. Reviews offer real-world insights and experiences from other users, while certifications from industry regulating bodies attest to compliance with safety and quality standards. Together, these elements form a comprehensive picture of reliability and quality assurance. In conclusion, galvanized iron tie wire remains an essential component across multiple sectors, cherished for its durability, flexibility, and resistance to the elements. Its continued relevance speaks to its unmatched ability to evolve alongside technological improvements while maintaining its foundational characteristics. For businesses and users alike, the ability to leverage this material's benefits effectively hinges on an understanding of its properties and trust in the manufacturer's expertise.

Among the key attributes that elevate one brand’s product over another is the wire’s tensile strength. A higher tensile strength indicates that the wire can handle significant stress without snapping, which is vital in applications that demand stability. Professionals in the field value this characteristic, as it often differentiates a top-tier product from its competitors. It's crucial for companies selling these wires to establish authority by providing detailed technical specifications and usage guidelines. Through authoritative content and demonstrative videos, businesses can build trust with their customers. This approach not only highlights the brand’s expertise but also aids users in making informed purchasing decisions based on their specific needs. Renowned brands usually offer insights into optimal storage solutions to prevent any potential degradation of the wire’s protective zinc layer. Recommendations often include storing the wire in cool, dry environments away from direct sunlight and other potential sources of chemical exposure. Such authoritative advice enhances a customer’s trust, reinforcing the brand's credibility. Ultimately, the trustworthiness of a company offering galvanized iron tie wire is often reflected in customer reviews and industry certifications. Reviews offer real-world insights and experiences from other users, while certifications from industry regulating bodies attest to compliance with safety and quality standards. Together, these elements form a comprehensive picture of reliability and quality assurance. In conclusion, galvanized iron tie wire remains an essential component across multiple sectors, cherished for its durability, flexibility, and resistance to the elements. Its continued relevance speaks to its unmatched ability to evolve alongside technological improvements while maintaining its foundational characteristics. For businesses and users alike, the ability to leverage this material's benefits effectively hinges on an understanding of its properties and trust in the manufacturer's expertise.

share:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025