- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 11, 2025 12:41

Back to list

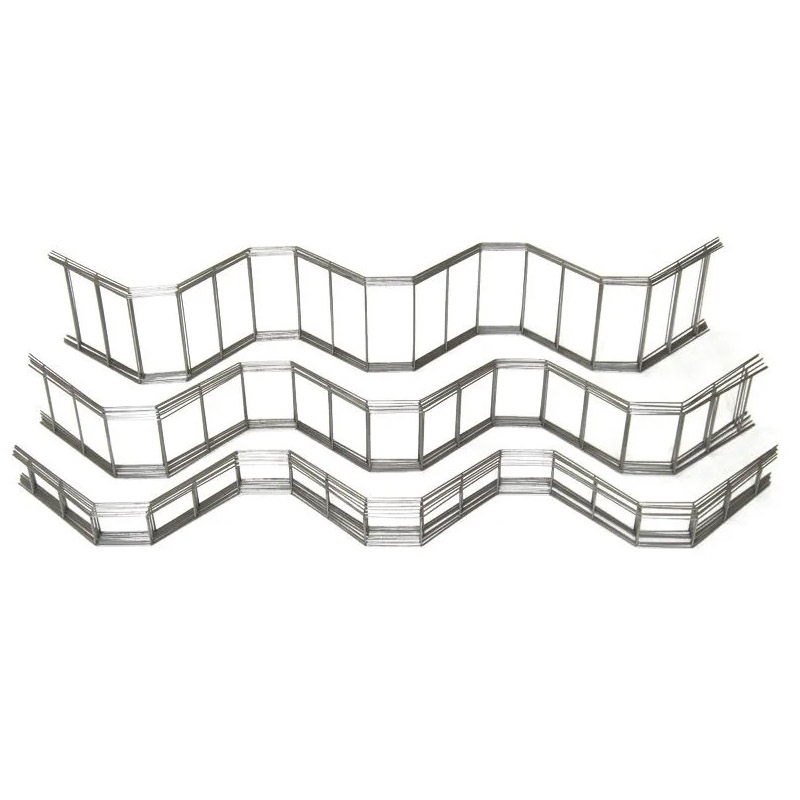

Continuous Wire

Cold rolled steel bars are a staple in various industries, renowned for their superior characteristics and diverse applications. As an expert with years of experience in the steel industry, I can attest to the transformative benefits that cold rolling brings to steel, enhancing its performance across multiple dimensions.

From the perspective of manufacturability, cold rolled steel bars simplify processes such as welding, machining, and fabrication. Their enhanced surface quality reduces the need for extensive surface preparation, streamlining production workflows and reducing costs. For manufacturers, these bars are a preferred raw material due to the consistency they bring, which is crucial for maintaining quality across large production runs. Quality control is of unprecedented importance in the realm of cold rolled steel bars. Manufacturers conduct rigorous testing to verify that the bars meet stringent industry standards, ensuring that they exhibit uniform hardness, tensile strength, and surface quality. These rigorous protocols establish a solid base of trust with industries relying on steel, affirming that every batch of cold rolled steel meets the necessary requirements for even the most demanding applications. For professionals seeking to maximize efficiency and performance in their projects, understanding the distinct benefits of cold rolled steel bars is essential. Their application ranges from providing structural integrity to delivering precision in complex mechanical systems, offering versatile solutions backed by robust material science. Innovation continues to drive the development of cold rolled steel technology, with research focusing on enhancing properties such as wear resistance and fatigue strength. These ongoing advancements not only extend the capabilities of the steel itself but also broaden the scope of industries that can benefit from its unique properties. As the landscape of material science evolves, cold rolled steel bars remain a pivotal component in the engineering and manufacturing sectors.

From the perspective of manufacturability, cold rolled steel bars simplify processes such as welding, machining, and fabrication. Their enhanced surface quality reduces the need for extensive surface preparation, streamlining production workflows and reducing costs. For manufacturers, these bars are a preferred raw material due to the consistency they bring, which is crucial for maintaining quality across large production runs. Quality control is of unprecedented importance in the realm of cold rolled steel bars. Manufacturers conduct rigorous testing to verify that the bars meet stringent industry standards, ensuring that they exhibit uniform hardness, tensile strength, and surface quality. These rigorous protocols establish a solid base of trust with industries relying on steel, affirming that every batch of cold rolled steel meets the necessary requirements for even the most demanding applications. For professionals seeking to maximize efficiency and performance in their projects, understanding the distinct benefits of cold rolled steel bars is essential. Their application ranges from providing structural integrity to delivering precision in complex mechanical systems, offering versatile solutions backed by robust material science. Innovation continues to drive the development of cold rolled steel technology, with research focusing on enhancing properties such as wear resistance and fatigue strength. These ongoing advancements not only extend the capabilities of the steel itself but also broaden the scope of industries that can benefit from its unique properties. As the landscape of material science evolves, cold rolled steel bars remain a pivotal component in the engineering and manufacturing sectors.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025