- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 04, 2025 08:13

Back to list

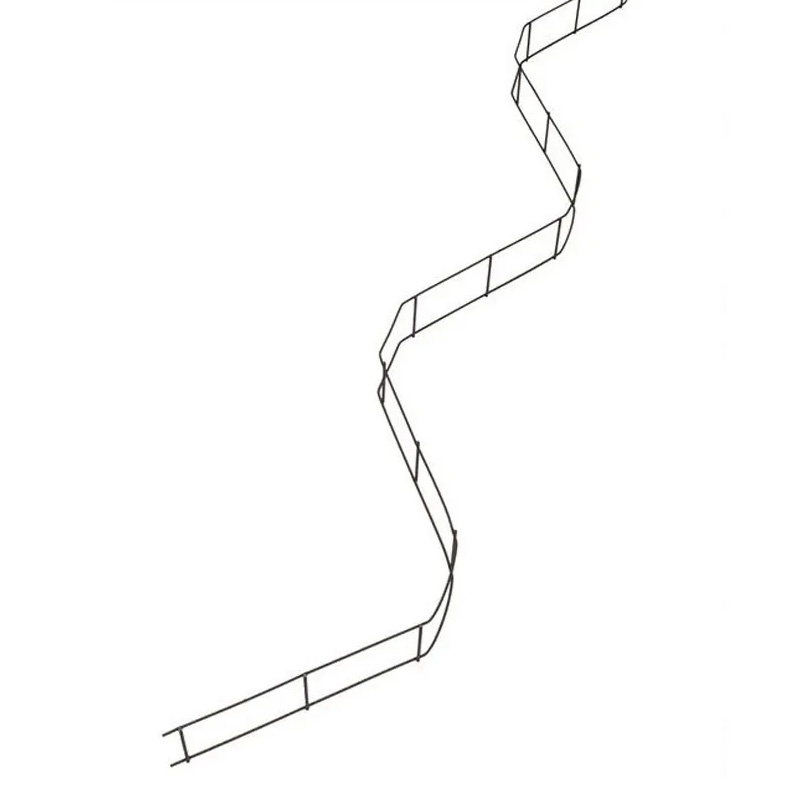

buy concrete mesh

Concrete iron mesh, an integral component in modern construction, is pivotal for enhancing the durability and strength of concrete structures. Recognized for its ability to reinforce concrete, this mesh, also known as reinforcing mesh or rebar mesh, has revolutionized the construction industry with its unparalleled efficacy and reliability.

Moreover, incorporating concrete iron mesh in construction projects benefits workflow efficiency. It streamlines the construction process by reducing the time needed for formwork setup and facilitating quicker concrete pouring. This not only accelerates project timelines but also translates into financial savings, an aspect that resonates well with industry stakeholders aiming to optimize resource allocation. An emerging trend in sustainable construction is the integration of recycled materials into iron mesh manufacturing. This innovation reduces waste and aligns with global efforts toward greener building methodologies. As professionals in this field, staying updated with such advancements is crucial to remain competitive and relevant. For those venturing into projects with unique structural demands, consulting with experts who specialize in concrete iron mesh can provide tailored solutions. Engaging with professionals ensures that the mesh specification aligns precisely with project requirements, achieving optimal performance. The discussion on concrete iron mesh cannot be complete without addressing its ergonomic features. Lightweight yet robust, its installation requires minimal labor-intensive handling, reducing workforce strain and potential onsite injuries. This feature is particularly advantageous on complex sites where maneuverability is restricted. In summation, the extensive advantages of concrete iron mesh stem from its exceptional strength, versatility, and compliance with safety standards. The array of benefits it offers helps streamline construction processes while safeguarding the structural guarantees of buildings. As an advocate for its application, I affirm the mesh’s crucial role in facilitating the construction of tomorrow’s resilient and sustainable infrastructures.

Moreover, incorporating concrete iron mesh in construction projects benefits workflow efficiency. It streamlines the construction process by reducing the time needed for formwork setup and facilitating quicker concrete pouring. This not only accelerates project timelines but also translates into financial savings, an aspect that resonates well with industry stakeholders aiming to optimize resource allocation. An emerging trend in sustainable construction is the integration of recycled materials into iron mesh manufacturing. This innovation reduces waste and aligns with global efforts toward greener building methodologies. As professionals in this field, staying updated with such advancements is crucial to remain competitive and relevant. For those venturing into projects with unique structural demands, consulting with experts who specialize in concrete iron mesh can provide tailored solutions. Engaging with professionals ensures that the mesh specification aligns precisely with project requirements, achieving optimal performance. The discussion on concrete iron mesh cannot be complete without addressing its ergonomic features. Lightweight yet robust, its installation requires minimal labor-intensive handling, reducing workforce strain and potential onsite injuries. This feature is particularly advantageous on complex sites where maneuverability is restricted. In summation, the extensive advantages of concrete iron mesh stem from its exceptional strength, versatility, and compliance with safety standards. The array of benefits it offers helps streamline construction processes while safeguarding the structural guarantees of buildings. As an advocate for its application, I affirm the mesh’s crucial role in facilitating the construction of tomorrow’s resilient and sustainable infrastructures.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025