- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 14, 2025 22:29

Back to list

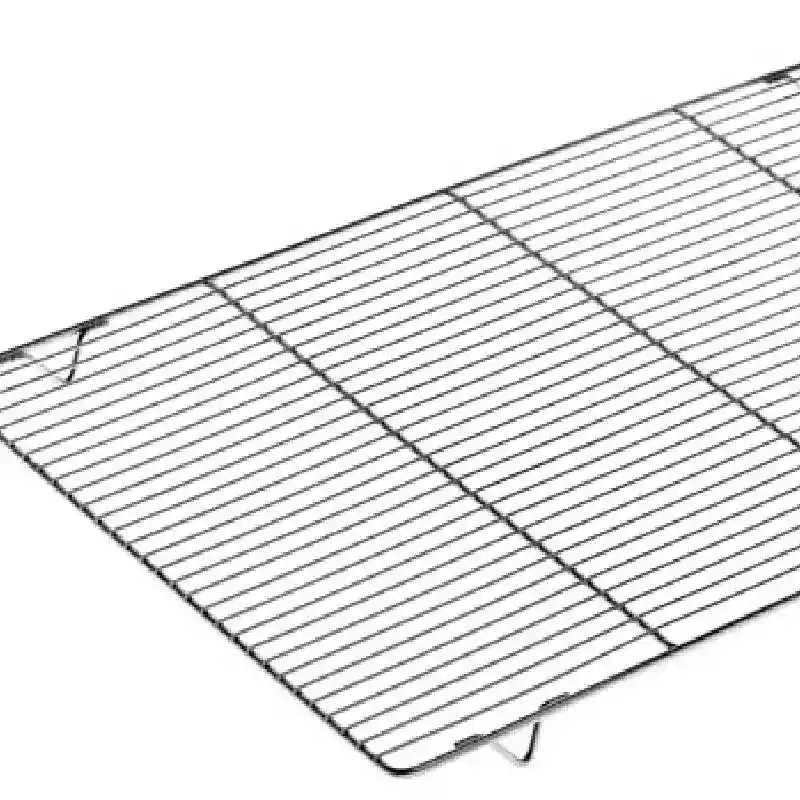

coated hardware mesh

Coated hardware mesh has become an essential component across various industries, known for its versatility, durability, and functionality. Incorporating coated hardware mesh into projects can lead to enhanced performance and longevity of applications. This article delves into the intricate benefits of coated hardware mesh and its impact on construction, agriculture, and manufacturing, providing substantial insights derived from real-life experiences and expert opinions.

From an environmental perspective, coated hardware mesh is esteemed for its sustainability contributions. The coating process often involves materials that are environmentally friendly, reducing the footprint traditionally associated with metallic products. Companies that adapt these eco-conscious practices in their mesh production not only align with global sustainability standards but also appeal to eco-aware consumers. Adoption of such practices promotes an elevated standard of environmental responsibility across industries demanding coated hardware mesh, ensuring that economic and ecological benefits go hand in hand. The trust placed in coated hardware mesh is founded on years of proven field experience and continuous advancements in material science. By adopting innovative coatings, manufacturers can offer products that meet the evolving demands of clients who prioritize long-lasting solutions, thereby enhancing the credibility of coated hardware mesh across professional domains. Clients who integrate coated hardware mesh into their projects vouch for its comprehensive utility, encompassing its anti-corrosive attributes, structural resilience, and design flexibility. In conclusion, coated hardware mesh not only signifies advanced material engineering but also stands as a testimony to its diverse applications across multiple sectors. It combines an ideal balance of strength, adaptability, and protection, offering unparalleled utility in challenging environments. By investing in coated hardware mesh, industries guarantee the reliability of their projects, a testament to its embedded expertise and authoritative reputation. This dedication to quality and innovation continues to drive the relevance and adoption of coated hardware mesh, ensuring its integral role in the future of industrial applications.

From an environmental perspective, coated hardware mesh is esteemed for its sustainability contributions. The coating process often involves materials that are environmentally friendly, reducing the footprint traditionally associated with metallic products. Companies that adapt these eco-conscious practices in their mesh production not only align with global sustainability standards but also appeal to eco-aware consumers. Adoption of such practices promotes an elevated standard of environmental responsibility across industries demanding coated hardware mesh, ensuring that economic and ecological benefits go hand in hand. The trust placed in coated hardware mesh is founded on years of proven field experience and continuous advancements in material science. By adopting innovative coatings, manufacturers can offer products that meet the evolving demands of clients who prioritize long-lasting solutions, thereby enhancing the credibility of coated hardware mesh across professional domains. Clients who integrate coated hardware mesh into their projects vouch for its comprehensive utility, encompassing its anti-corrosive attributes, structural resilience, and design flexibility. In conclusion, coated hardware mesh not only signifies advanced material engineering but also stands as a testimony to its diverse applications across multiple sectors. It combines an ideal balance of strength, adaptability, and protection, offering unparalleled utility in challenging environments. By investing in coated hardware mesh, industries guarantee the reliability of their projects, a testament to its embedded expertise and authoritative reputation. This dedication to quality and innovation continues to drive the relevance and adoption of coated hardware mesh, ensuring its integral role in the future of industrial applications.

share:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025