- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

black annealed wire suppliers

Understanding Black Annealed Wire and Its Suppliers

Black annealed wire is a versatile material widely utilized across various industries, particularly in construction, manufacturing, and agriculture. This wire, characterized by its dark, matte finish and superior ductility, is made from low-carbon steel that undergoes a specific annealing process. The process involves heating the wire to a high temperature and then allowing it to cool slowly, which enhances its workability and overall performance. Due to its unique properties, black annealed wire is an essential component in numerous applications, and its suppliers play a crucial role in ensuring that businesses have access to high-quality materials.

What is Black Annealed Wire?

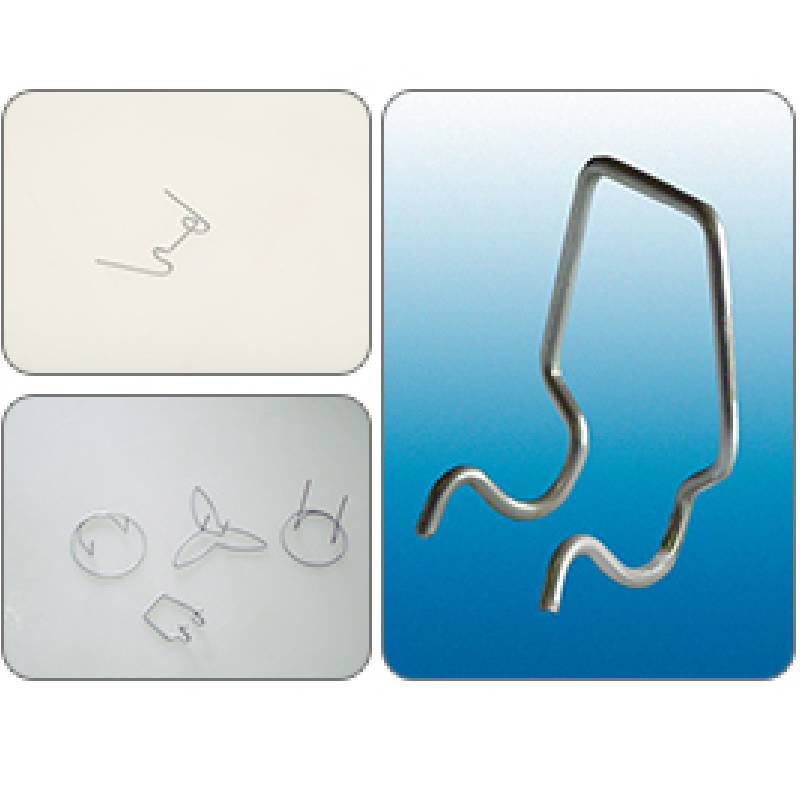

Black annealed wire is primarily used for binding and tying materials together. Its softened structure allows it to be easily bent and twisted, making it an excellent choice for securing items in place. Common uses include constructing fences, tying rebar in concrete projects, and creating wire mesh for various construction applications. Its corrosion-resistant finish also makes it suitable for outdoor use, where it is exposed to the elements.

The wire's manufacturing process involves several steps, beginning with the production of low-carbon steel. Once the wire is drawn to the desired diameter, it is subjected to an annealing process. After annealing, the wire is often coated with a rust-preventing agent to enhance its longevity. The end product is a flexible wire that can withstand tension without breaking, making it ideal for a range of industrial applications.

The Importance of Quality Suppliers

When seeking black annealed wire, choosing the right supplier is critical. Quality suppliers not only provide high-grade materials, but they also offer consistent delivery and customer service that can influence project outcomes. A reliable supplier should ideally be able to furnish the wire in various specifications to meet different project needs, including various diameters and tensile strengths.

Factors to Consider When Choosing a Supplier

black annealed wire suppliers

1. Quality Assurance It is imperative to select suppliers that adhere to strict quality control measures. Certification from relevant bodies, such as ISO certification, can indicate that a supplier follows industry standards and produces reliable products.

2. Reputation Research the supplier's market reputation. Customer reviews and feedback can provide insights into their reliability, product quality, and service level.

3. Pricing While competitive pricing is essential, the cheapest option is not always the best. Evaluate the cost relative to the quality of the product and the services provided. A good supplier should offer a balance between cost and quality.

4. Range of Products A supplier that offers a diverse range of black annealed wire products can provide flexibility for different project needs. This may also include customization options for specific applications.

5. Customer Service A responsive and knowledgeable customer service team is crucial. They should be able to provide technical support, assist in placing orders, and handle any potential issues promptly.

6. Delivery Times Consider the supplier's ability to meet deadlines, particularly if the wire is needed for ongoing projects. Timely delivery is essential to keep construction schedules on track.

Conclusion

In summary, black annealed wire serves as a fundamental component in various industries, making it essential to source it from reliable suppliers. By focusing on quality, reputation, pricing, product range, customer service, and delivery times, businesses can establish strong relationships with suppliers that enhance their operational efficiency. In a world that increasingly values quality and reliability, cultivating relationships with trustworthy black annealed wire suppliers can lead to long-term success and growth for any enterprise involved in construction, manufacturing, or agriculture.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025