- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 14, 2025 13:00

Back to list

binding iron wire

Iron wire is an essential component in various industries, offering a perfect blend of durability, flexibility, and cost-effectiveness. Its multifaceted applications range from construction to art, making it an invaluable resource across different sectors. Understanding the nuances of iron wire, from its manufacturing process to its diverse uses, can help businesses and consumers make informed decisions when selecting the right product for their needs.

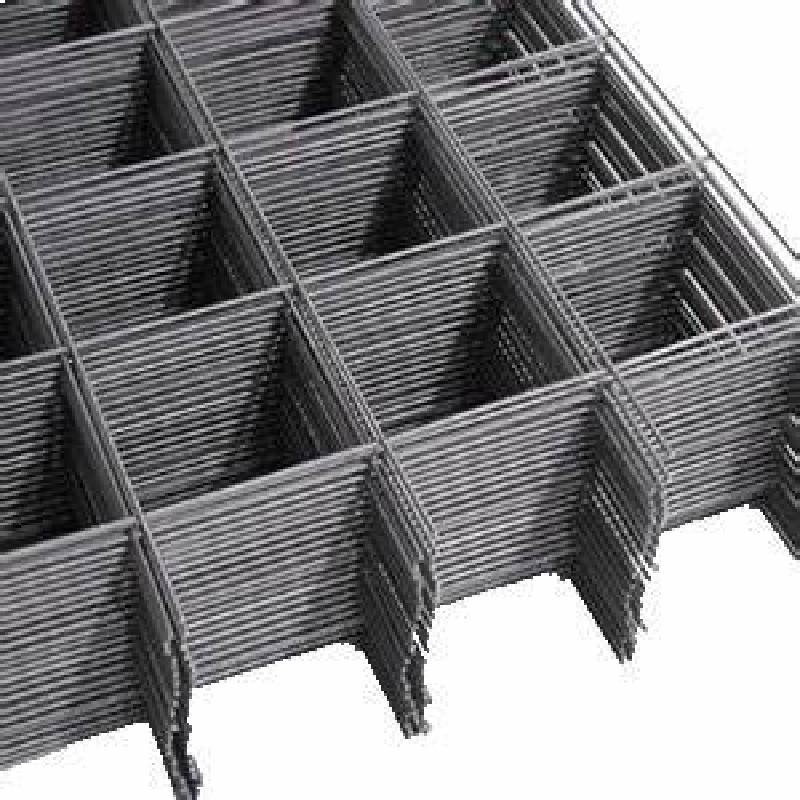

Beyond these applications, iron wire serves essential functions in the manufacturing sector. It is used in the production of wire mesh, nails, and springs, among other products. Its utility in everyday items underscores its importance in our daily lives, demonstrating its essential role in both industrial and domestic settings. When selecting iron wire, it is crucial to consider factors like gauge, coating, and application-specific requirements. The gauge of the wire determines its thickness, directly affecting its strength and flexibility. Depending on the use, iron wire can be coated with various materials like zinc or plastic to enhance its resistance to corrosion and environmental factors. For businesses involved in the sale and distribution of iron wire, establishing credibility and authority in the market is essential. Offering high-quality products backed by certifications and adhering to industry standards builds trust with consumers. Providing comprehensive product information and expert advice helps customers make informed purchasing decisions, fostering long-term relationships. In conclusion, the right choice of iron wire depends on understanding its properties and aligning them with specific needs. Its wide range of applications, coupled with its inherent qualities, make it an indispensable material in numerous fields. By focusing on expertise in production and application, and maintaining trust through quality assurance, businesses can effectively leverage the potential of iron wire in their offerings.

Beyond these applications, iron wire serves essential functions in the manufacturing sector. It is used in the production of wire mesh, nails, and springs, among other products. Its utility in everyday items underscores its importance in our daily lives, demonstrating its essential role in both industrial and domestic settings. When selecting iron wire, it is crucial to consider factors like gauge, coating, and application-specific requirements. The gauge of the wire determines its thickness, directly affecting its strength and flexibility. Depending on the use, iron wire can be coated with various materials like zinc or plastic to enhance its resistance to corrosion and environmental factors. For businesses involved in the sale and distribution of iron wire, establishing credibility and authority in the market is essential. Offering high-quality products backed by certifications and adhering to industry standards builds trust with consumers. Providing comprehensive product information and expert advice helps customers make informed purchasing decisions, fostering long-term relationships. In conclusion, the right choice of iron wire depends on understanding its properties and aligning them with specific needs. Its wide range of applications, coupled with its inherent qualities, make it an indispensable material in numerous fields. By focusing on expertise in production and application, and maintaining trust through quality assurance, businesses can effectively leverage the potential of iron wire in their offerings.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025