- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Properties and Applications of Beryllium Copper Compression Springs in Engineering Solutions

Beryllium Copper Compression Springs An Overview

Beryllium copper, an alloy of copper with a small percentage of beryllium (typically between 0.5% to 3%), is known for its impressive mechanical properties, exceptional conductivity, and resistance to corrosion. One of the most significant applications of this alloy is in the manufacturing of compression springs. These springs are highly valued in various industries due to their unique combination of strength, elasticity, and thermal stability.

Properties of Beryllium Copper

Beryllium copper is recognized for its high tensile strength and hardness, which makes it an ideal material for producing compression springs. The alloy can achieve tensile strengths of up to 200,000 psi, making it one of the toughest copper alloys available. In addition to physical strength, beryllium copper has excellent fatigue resistance, which is crucial for compression springs that experience repeated cycles of compression and release. Furthermore, this alloy also possesses good electrical and thermal conductivity, allowing it to be used in applications where electrical connections are essential.

One of the unique aspects of beryllium copper is its ability to retain its mechanical properties at elevated temperatures. This quality is particularly beneficial in settings where springs may be exposed to varying thermal environments. Moreover, beryllium copper is inherently resistant to corrosion, enabling its use in hostile environments where moisture or chemicals would typically cause degradation.

Applications of Beryllium Copper Compression Springs

Beryllium copper compression springs have a wide range of applications across different sectors. In the electronics industry, these springs are utilized in various components, including switches, relays, and connectors, where reliable performance and conductivity are crucial. Their ability to withstand mechanical stress while maintaining conductivity makes them ideal for high-performance electrical applications.

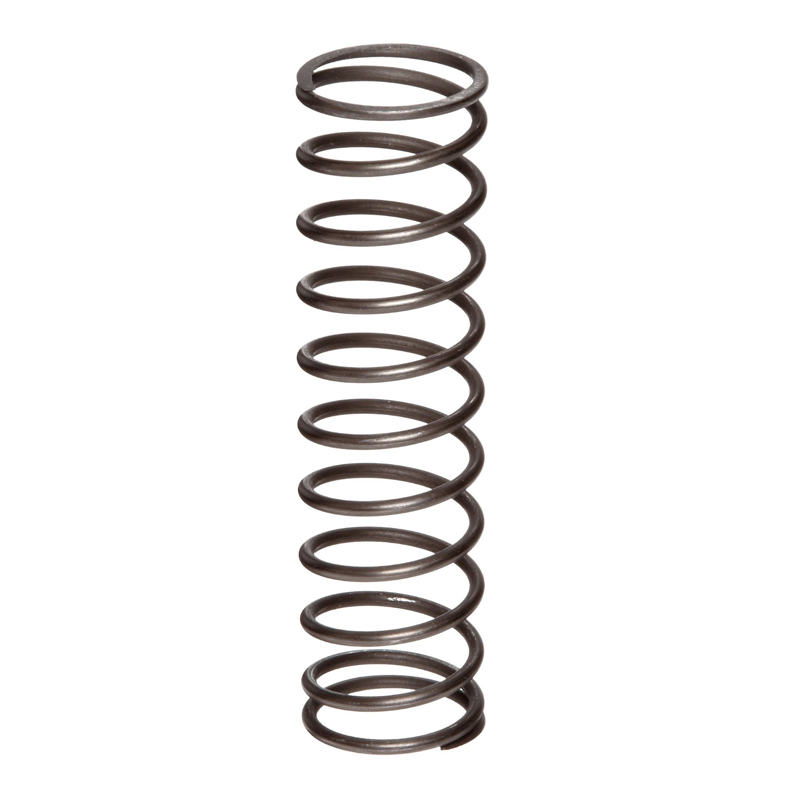

beryllium copper compression springs

In the automotive industry, beryllium copper compression springs are used in critical components such as suspension systems and engine parts. These springs provide the necessary support and stability while ensuring longevity and reliability under demanding conditions. The aerospace sector also benefits from this alloy, where weight reduction and strength are paramount. Compression springs made from beryllium copper are used in landing gear, control systems, and a host of other critical applications.

The medical field also sees the use of beryllium copper compression springs. Medical devices, such as surgical instruments and diagnostic equipment, require precision and reliability, making this alloy a suitable choice. The biocompatibility of beryllium copper also plays a role in its application within medical instrumentation.

Advantages of Beryllium Copper Compression Springs

The primary advantages of using beryllium copper for compression springs include its strength-to-weight ratio, the ability to withstand harsh environmental conditions, and excellent fatigue resistance. These properties allow for the design of springs that are not only strong but also lightweight, which is particularly beneficial in applications where minimizing weight is crucial.

Another advantage is the alloy's ability to be manufactured into intricate designs, allowing for custom spring solutions to meet specific requirements. This versatility in design, combined with the ability to produce springs in various sizes and configurations, makes beryllium copper compression springs highly sought after in both standard and bespoke applications.

Conclusion

Beryllium copper compression springs represent a fusion of strength, resilience, and versatility. Their wide-ranging applications across various industries underscore their importance in modern engineering and manufacturing. As industries continue to seek materials that provide enhanced performance under challenging conditions, beryllium copper remains a top choice for compression spring manufacturing. Whether in electronics, automotive, aerospace, or medical devices, the benefits of beryllium copper compression springs facilitate the advancement of technology and design. With their unique combination of properties, these springs are set to play a vital role in innovative solutions for years to come.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025