- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Galvanized Iron Binding Wire - Durable and Versatile Solutions

Understanding Galvanized Iron Binding Wire A Versatile Solution for Modern Needs

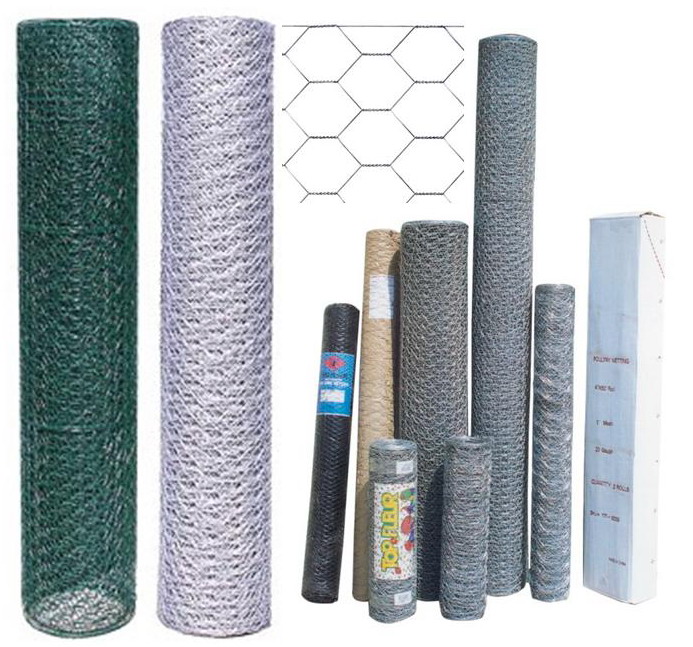

Galvanized iron binding wire has become a staple in various industries due to its strength, corrosion resistance, and versatility. Made from mild steel wire that has been coated with zinc through a process called galvanization, this material offers a host of benefits that make it suitable for multiple applications, from construction to agriculture.

One of the primary advantages of galvanized iron binding wire is its excellent resistance to rust and corrosion. The zinc coating serves as a protective barrier, preventing moisture and air from reaching the underlying steel. This feature is particularly valuable in outdoor settings or areas with high humidity, where traditional iron wire would quickly deteriorate. In fact, galvanized wire can withstand the elements for years, making it a preferred choice for long-term use in various projects.

In the construction industry, galvanized iron binding wire is extensively used for securing and tying rebar and wire mesh. The strength and durability of the wire ensure that concrete structures are reinforced adequately, providing stability and support. Moreover, the ease of use of this binding wire allows construction workers to quickly and efficiently tie up materials, reducing labor time and increasing productivity on-site.

In addition to construction, galvanized iron binding wire finds an essential role in the agricultural sector. Farmers utilize this wire for fencing, trellising, and securing plants. The strong yet flexible nature of the wire allows for sturdy plant support, ensuring that crops grow upright and are less susceptible to damage from wind or rain. Furthermore, its rust-resistant properties make it ideal for outdoor use in various climate conditions, safeguarding investments in crops and livestock fencing.

galvanized iron binding wire

The versatility of galvanized iron binding wire extends beyond construction and agriculture. It is also widely used in crafting and DIY projects. Hobbyists and craftsmen appreciate the wire's flexibility, as it can be bent and twisted to create intricate designs, sculptures, or functional items such as hanging planters and garden structures. The wire can easily be cut to length and manipulated without breaking, allowing for endless creative possibilities.

Another advantage of galvanized iron binding wire is its cost-effectiveness. Compared to other materials like stainless steel or plastic, galvanized wire offers similar benefits at a fraction of the price. This affordability makes it accessible for various applications, enabling more people to utilize it for their needs without compromising on quality.

It is essential, however, to choose the right gauge and strength of galvanized iron binding wire for specific applications. Different projects may require different strengths, and using the appropriate wire ensures that it performs well under pressure. Manufacturers often provide guidance on selecting the ideal wire, educating consumers on the best practices for installation and use.

In conclusion, galvanized iron binding wire is a highly beneficial material that accommodates a wide range of applications in construction, agriculture, crafting, and more. Its rust resistance, strength, flexibility, and cost-effectiveness make it a valuable resource in today's world. As industries continue to innovate and seek reliable materials, galvanized iron binding wire will undoubtedly remain a favored choice for professionals and hobbyists alike.

share:

-

Wire Tension Springs for Diverse ApplicationsNewsMay.27,2025

-

Snake SpacersNewsMay.27,2025

-

Sacrificial Formwork Solutions for ConstructionNewsMay.27,2025

-

Iron Binding Wire for Your Construction NeedsNewsMay.27,2025

-

Enhance Your Construction Projects with Wire SpacerNewsMay.27,2025

-

Black Annealed Wires for Diverse ApplicationsNewsMay.27,2025

-

Strong Wall Support ChoicesNewsMay.23,2025