- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mrz . 03, 2025 12:50

Back to list

weld mesh concrete reinforcement

Weld mesh concrete reinforcement has transformed the construction industry with its efficiency and resilience. As a versatile material, weld mesh provides a sturdy skeleton for concrete structures, enhancing their strength and durability. This exploration offers a detailed understanding of its benefits, applications, and best practices, drawing from real-world experiences and expert insights.

Weld mesh also exemplifies high manufacturability, enabling customization to meet specific project requirements. Manufacturers can tailor the mesh size, wire diameter, and overall dimensions to accommodate unique structural needs. This adaptability has proven crucial in large infrastructure projects where the demands vary significantly from standard building codes. Moreover, maintaining consistent quality during production enhances the credibility of the weld mesh as a dependable and trustworthy reinforcement material. From a sustainability perspective, the use of weld mesh in concrete reinforcement supports environmentally friendly construction practices. The material itself is recyclable and contributes to reduced waste on construction sites due to its pre-fabricated nature. Furthermore, the enhanced durability of structures reinforced with weld mesh leads to less frequent repairs and lower material consumption over the building's lifetime, aligning with sustainable development goals. For construction and architectural professionals aiming to optimize concrete structures, choosing weld mesh as a reinforcement method offers undeniable advantages. Engaging with qualified suppliers and understanding the intricacies of specific applications ensures that the benefits of weld mesh are fully realized. It is crucial for decision-makers in construction projects to collaborate with structural engineers and material specialists to determine the most effective use of weld mesh, taking into account local building regulations and environmental conditions. With its proven track record, weld mesh concrete reinforcement continues to define the standards of modern construction. As the industry advances, embracing innovative reinforcement methods like weld mesh not only enhances structural safety but also supports the evolution of sustainable building practices. Trust in weld mesh’s capability is founded on extensive expertise, authoritative evidence, and an unwavering promise of reliability and efficiency in concrete reinforcement.

Weld mesh also exemplifies high manufacturability, enabling customization to meet specific project requirements. Manufacturers can tailor the mesh size, wire diameter, and overall dimensions to accommodate unique structural needs. This adaptability has proven crucial in large infrastructure projects where the demands vary significantly from standard building codes. Moreover, maintaining consistent quality during production enhances the credibility of the weld mesh as a dependable and trustworthy reinforcement material. From a sustainability perspective, the use of weld mesh in concrete reinforcement supports environmentally friendly construction practices. The material itself is recyclable and contributes to reduced waste on construction sites due to its pre-fabricated nature. Furthermore, the enhanced durability of structures reinforced with weld mesh leads to less frequent repairs and lower material consumption over the building's lifetime, aligning with sustainable development goals. For construction and architectural professionals aiming to optimize concrete structures, choosing weld mesh as a reinforcement method offers undeniable advantages. Engaging with qualified suppliers and understanding the intricacies of specific applications ensures that the benefits of weld mesh are fully realized. It is crucial for decision-makers in construction projects to collaborate with structural engineers and material specialists to determine the most effective use of weld mesh, taking into account local building regulations and environmental conditions. With its proven track record, weld mesh concrete reinforcement continues to define the standards of modern construction. As the industry advances, embracing innovative reinforcement methods like weld mesh not only enhances structural safety but also supports the evolution of sustainable building practices. Trust in weld mesh’s capability is founded on extensive expertise, authoritative evidence, and an unwavering promise of reliability and efficiency in concrete reinforcement.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

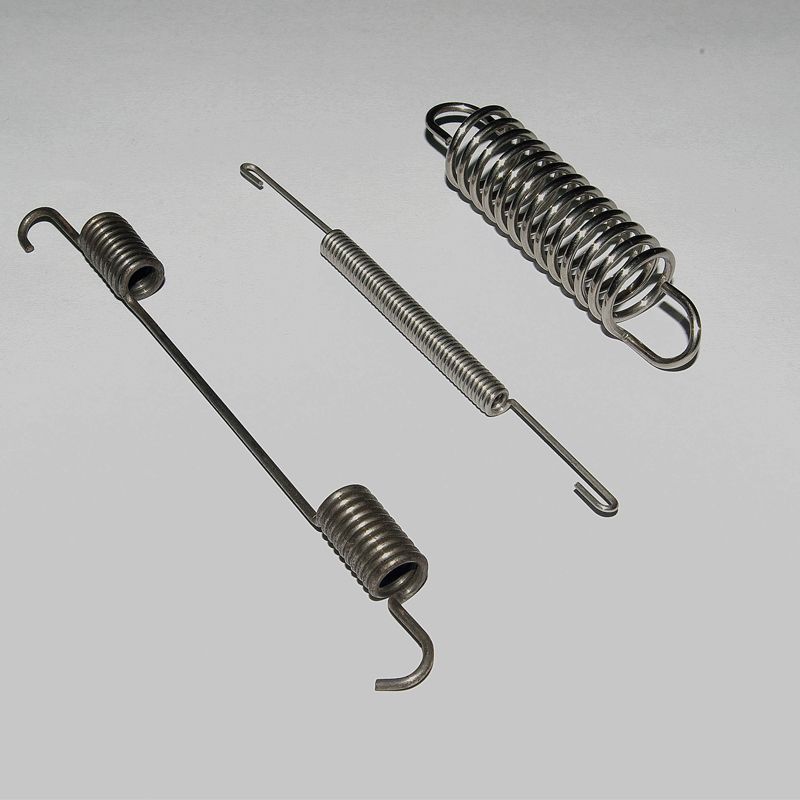

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025