- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mrz . 06, 2025 11:29

Back to list

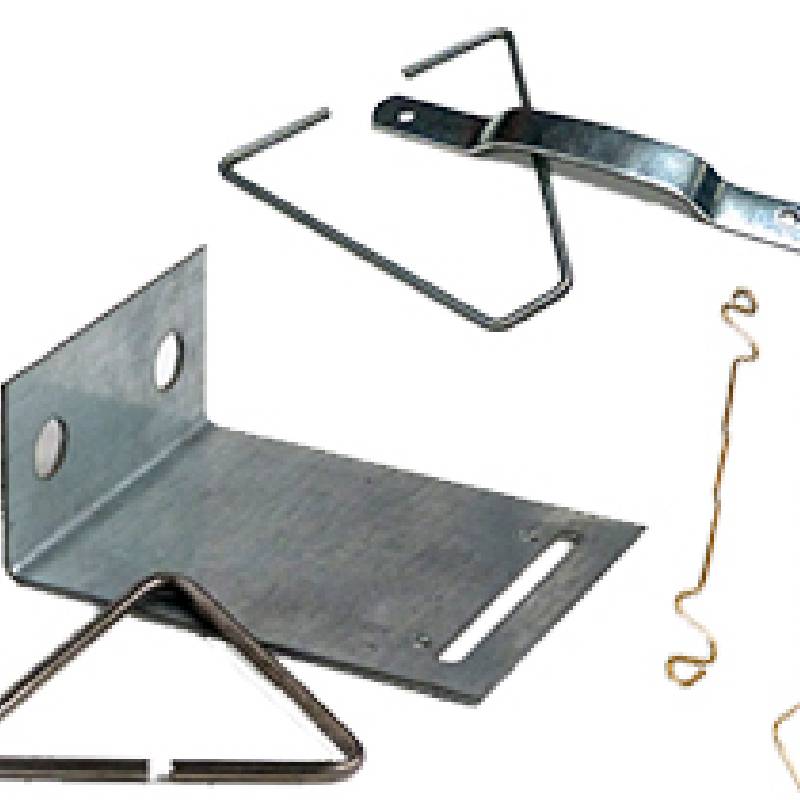

utility springs

Unlocking the Potential of Utility Springs Elevating Product Performance and Innovation

Authoritativeness Industry Standards and Best Practices Utility springs adhere to rigorous industry standards to ensure safety and performance. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) provide guidelines that govern the manufacturing and testing processes for springs. Adhering to these standards is critical for manufacturers to maintain quality and build trust with clients. Companies leading in the production of utility springs often participate in collaborative research initiatives, contributing to the advancement of industry knowledge and best practices. Trustworthiness Building Reliability and Confidence The reliability of utility springs is paramount, particularly in mission-critical applications where failure could lead to severe consequences. Manufacturers are increasingly prioritizing quality assurance processes, employing state-of-the-art testing equipment to simulate various operational stresses and predict the lifespan of their products. This commitment to quality fosters trust among consumers and industry partners alike. In addition, transparent supply chain practices and ethical sourcing of materials further enhance the trustworthiness of utility spring manufacturers. Utility Springs in Future Innovations The future of utility springs lies in their integration into smart technologies and environmentally sustainable designs. As industries push towards greater efficiency and reduced environmental impact, utility springs are poised to evolve in tandem. Developments in smart materials and mechatronics are set to revolutionize spring functions, enabling responsive and adaptive behaviors in the face of changing operational demands. Moreover, the drive towards recyclability and sustainable production practices will likely shape the next generation of utility springs. In conclusion, utility springs, though often overlooked, are foundational to myriad products that enhance our daily lives. Through a blend of real-world experience, engineering expertise, authoritative standards, and a commitment to reliability, utility springs continue to drive innovation and performance in various sectors. As industries evolve, so too will the humble utility spring, cementing its role as a critical component of technological advancement and sustainability.

Authoritativeness Industry Standards and Best Practices Utility springs adhere to rigorous industry standards to ensure safety and performance. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) provide guidelines that govern the manufacturing and testing processes for springs. Adhering to these standards is critical for manufacturers to maintain quality and build trust with clients. Companies leading in the production of utility springs often participate in collaborative research initiatives, contributing to the advancement of industry knowledge and best practices. Trustworthiness Building Reliability and Confidence The reliability of utility springs is paramount, particularly in mission-critical applications where failure could lead to severe consequences. Manufacturers are increasingly prioritizing quality assurance processes, employing state-of-the-art testing equipment to simulate various operational stresses and predict the lifespan of their products. This commitment to quality fosters trust among consumers and industry partners alike. In addition, transparent supply chain practices and ethical sourcing of materials further enhance the trustworthiness of utility spring manufacturers. Utility Springs in Future Innovations The future of utility springs lies in their integration into smart technologies and environmentally sustainable designs. As industries push towards greater efficiency and reduced environmental impact, utility springs are poised to evolve in tandem. Developments in smart materials and mechatronics are set to revolutionize spring functions, enabling responsive and adaptive behaviors in the face of changing operational demands. Moreover, the drive towards recyclability and sustainable production practices will likely shape the next generation of utility springs. In conclusion, utility springs, though often overlooked, are foundational to myriad products that enhance our daily lives. Through a blend of real-world experience, engineering expertise, authoritative standards, and a commitment to reliability, utility springs continue to drive innovation and performance in various sectors. As industries evolve, so too will the humble utility spring, cementing its role as a critical component of technological advancement and sustainability.

share:

Next:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025