- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Design and Applications of Long Coil Springs in Mechanical Systems

Understanding Long Coil Springs Applications, Benefits, and Design

Long coil springs are a vital component in various mechanical systems, offering flexibility, strength, and durability. These springs are characterized by their elongated shape, which allows them to store and release energy efficiently. In this article, we will explore the applications, benefits, and design considerations surrounding long coil springs.

Applications of Long Coil Springs

Long coil springs are utilized across multiple industries due to their versatility. In the automotive sector, they are commonly found in suspension systems. These springs help absorb shocks and maintain vehicle stability, contributing to a smoother ride for passengers. In machinery, long coil springs provide tension and support in conveyors and other equipment, ensuring operational efficiency.

In the realm of aerospace, long coil springs play a crucial role in various applications, including landing gear systems and control surfaces. Their ability to withstand cyclic stresses makes them ideal for high-performance environments. Furthermore, these springs have found applications in consumer electronics, industrial equipment, and even medical devices, providing necessary force and resilience.

Benefits of Long Coil Springs

One of the primary advantages of long coil springs is their ability to absorb and store energy effectively

. This characteristic is essential for applications where shock absorption is critical. By compressing and expanding, these springs help mitigate impacts and vibrations, ultimately prolonging the lifespan of other components in the system.Long coil springs also exhibit excellent fatigue resistance. This quality makes them suitable for applications subjected to repeated cyclic loading. Their design allows for a high degree of flexibility while maintaining structural integrity, ensuring reliable performance over time.

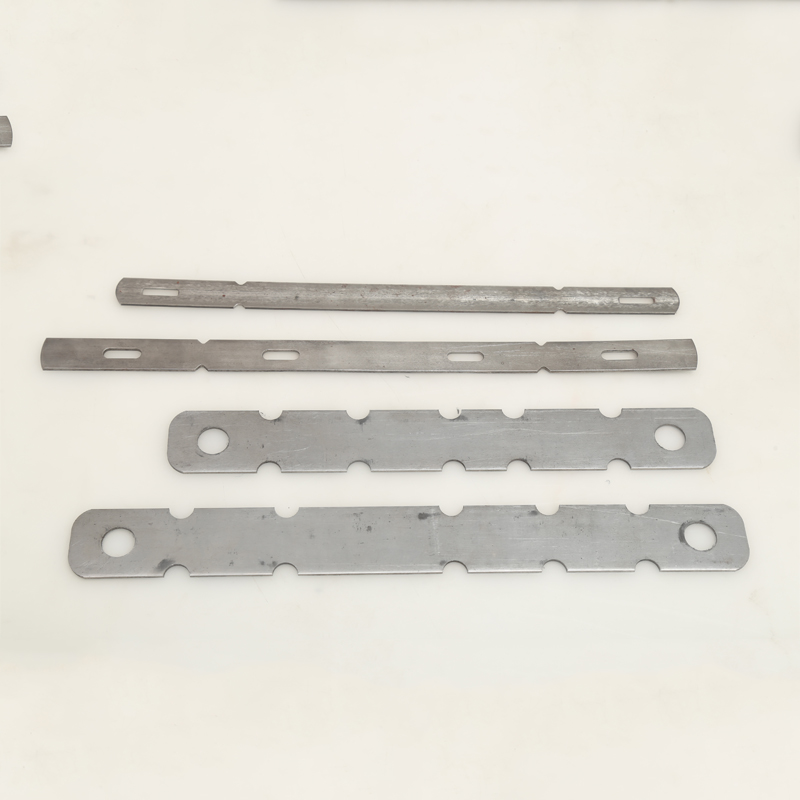

long coil spring

Additionally, long coil springs require minimal maintenance, which is a significant advantage for industries aiming to reduce operational costs. Once properly installed, these springs can function effectively without frequent interventions, providing peace of mind to engineers and operators.

Design Considerations

When designing long coil springs, several factors need to be taken into account to ensure optimal performance. The material selection is crucial; steel alloys are commonly used for their high tensile strength and fatigue resistance. However, for specific applications, materials like stainless steel or composite materials may be preferred for their corrosion resistance and lightweight properties.

The spring's diameter, free length, and number of active coils must also be considered. These dimensions directly affect the spring's load capacity and its ability to compress or extend under applied forces. Engineers often use spring design software to calculate the required specifications based on the expected loads and intended functionality.

Moreover, surface treatments and coatings can enhance the performance and longevity of long coil springs. Processes such as shot peening, coating with anti-corrosive materials, or heat treatment can significantly improve fatigue life and wear resistance.

Conclusion

Long coil springs are indispensable components in a wide array of applications, providing solutions that range from automotive suspensions to aerospace engineering. Their ability to absorb shocks, deliver consistent force, and resist fatigue makes them a preferred choice for many engineers.

As industries continue to evolve, the demand for reliable and efficient components like long coil springs will only grow. Understanding their applications, benefits, and design considerations is essential for anyone involved in mechanical design or engineering. By leveraging the unique properties of long coil springs, engineers can create more robust and efficient systems that meet the demands of modern technology.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025