- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

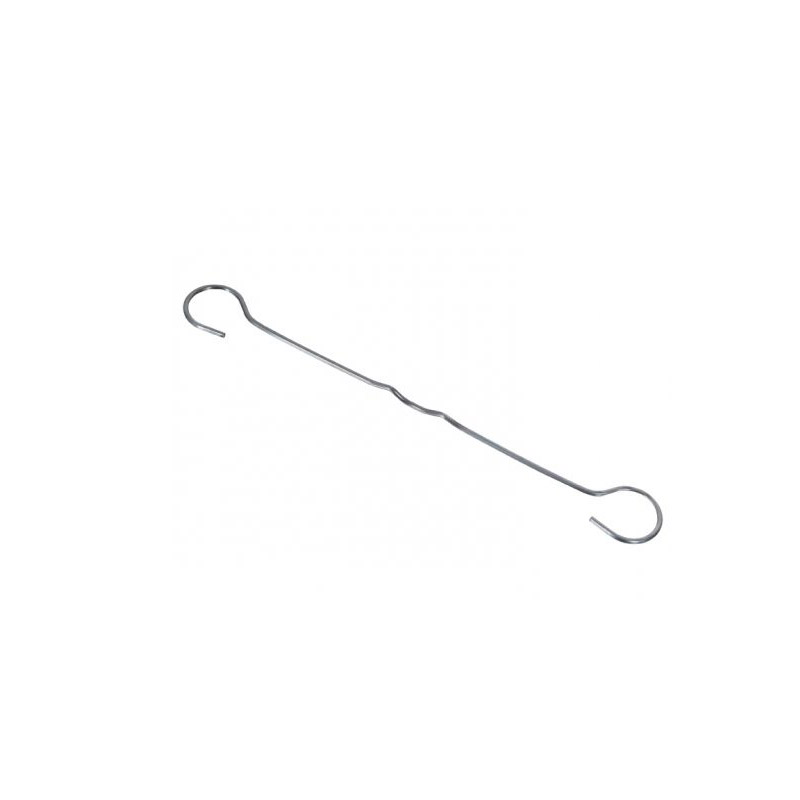

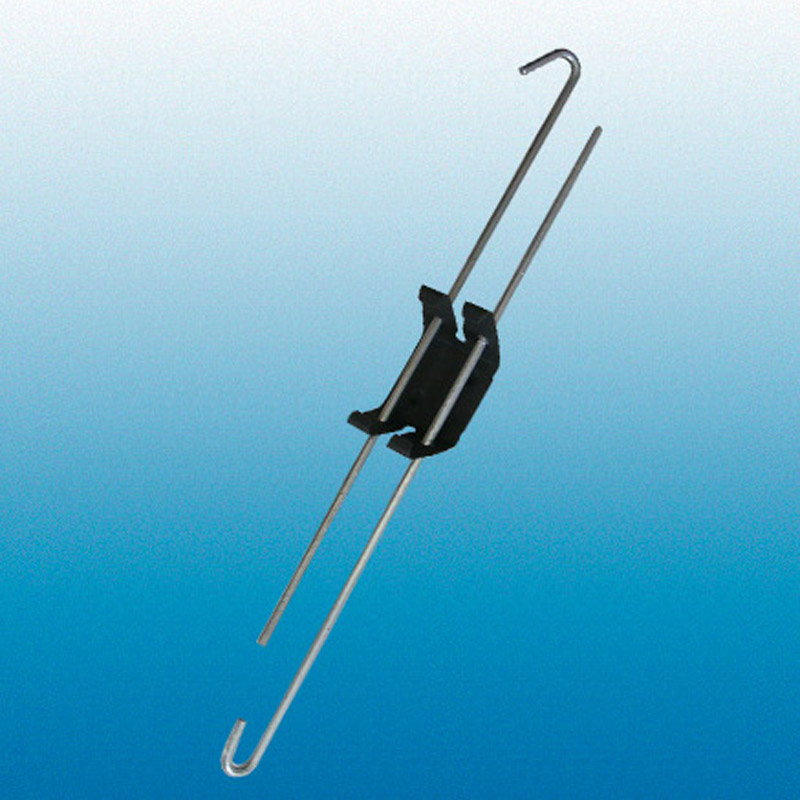

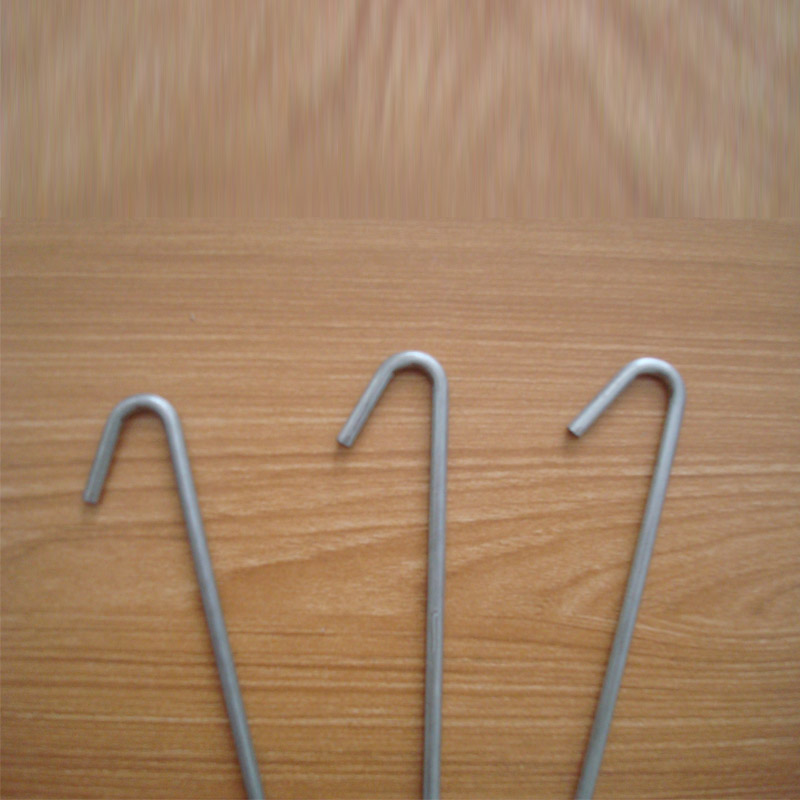

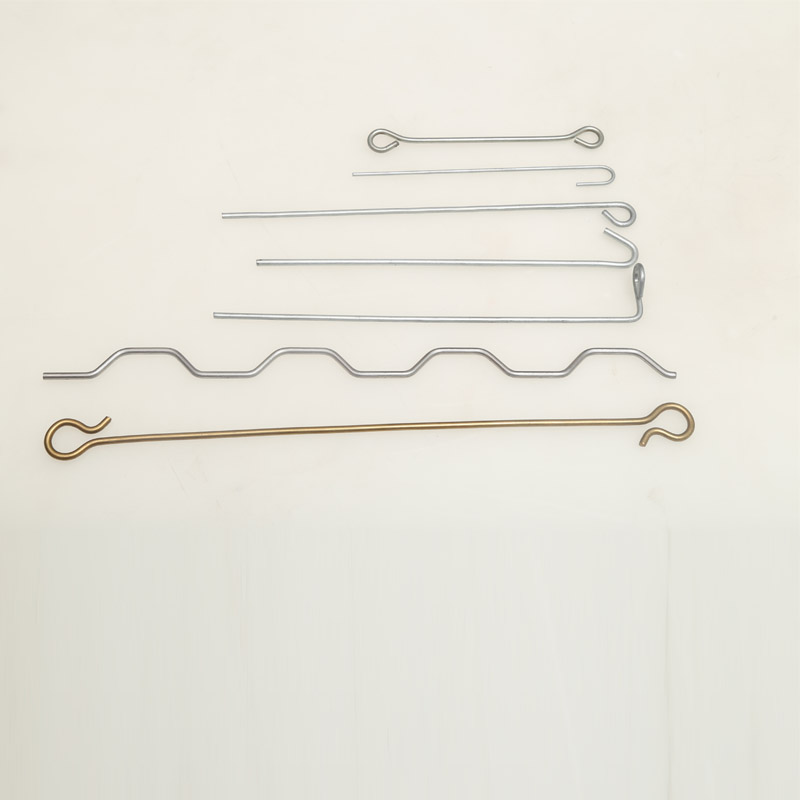

Adjustable & Heavy-Duty Ceiling Suspended Wire Hanger

In the complex world of industrial infrastructure, the integrity of piping systems is paramount. A critical, yet often overlooked, component ensuring this integrity is the Celling Suspended Wire Hanger. This guide provides an in-depth exploration of these essential supports, covering everything from industry trends and technical specifications to manufacturing processes and real-world applications. We will demonstrate why choosing a high-quality, precision-engineered hanger is a long-term investment in safety, efficiency, and operational reliability.

Industry Trends & Market Dynamics for Pipe Hanger Systems

The global market for pipe hangers and supports is witnessing significant growth, projected to expand at a CAGR of 5.2% from 2023 to 2030. This expansion is driven by several key factors: massive investments in infrastructure projects worldwide (especially in the energy and water treatment sectors), increasingly stringent industrial safety regulations, and a growing demand for durable, corrosion-resistant materials. The trend is shifting from basic, generic supports to sophisticated, engineered solutions like the Celling Suspended Wire Hanger, which are designed to handle complex load calculations, thermal expansion, and seismic activity. Modern projects demand components that comply with international standards such as ANSI/MSS SP-58 and ISO 9001, pushing manufacturers towards higher quality control and material traceability.

Furthermore, the focus on preventative maintenance and extending the lifespan of industrial plants has amplified the need for high-performance hangers. Materials like Grade 316 Stainless Steel and specialized alloys are becoming standard in corrosive environments like petrochemical plants and offshore platforms. The integration of digital tools for design and stress analysis, such as BIM (Building Information Modeling) and FEA (Finite Element Analysis), is also transforming how Celling Suspended Wire Hanger systems are specified and installed, ensuring optimal placement and performance from day one.

Core Technical Parameters: Understanding the Specifications

Selecting the correct Celling Suspended Wire Hanger requires a thorough understanding of its technical parameters. These specifications are not just numbers; they are critical indicators of the hanger's performance, safety, and suitability for a specific application. Below is a comprehensive table detailing the key specifications for our range of hangers.

| Parameter | Specification / Range | Technical Significance |

|---|---|---|

| Product Name | Celling Suspended Wire Hanger | Official designation for identification and ordering. |

| Applicable Pipe Size (NPS) | 1/2" to 36" (DN15 to DN900) | Defines the nominal pipe size the hanger is designed to support. Critical for proper fit and load distribution. |

| Material Grades | Carbon Steel (A36, Q235B), Stainless Steel (SS304, SS316, SS316L), Alloy Steel (ASTM A387) | Determines corrosion resistance, temperature range, and strength. SS316 is ideal for marine/chemical environments; Carbon Steel is for general use. |

| Maximum Load Capacity | Up to 25,000 lbs (11,340 kg) - Varies by size and material | The maximum vertical load the hanger can safely support. A critical safety factor, typically calculated with a 3:1 or 5:1 safety margin. |

| Temperature Range | -50°F to 1200°F (-45°C to 650°C) | The operational temperature range. High-temperature applications require specific alloy steels to prevent creep and strength loss. |

| Finish / Coating | Hot-Dip Galvanized (HDG), Electro-Galvanized, Epoxy Coated, Unfinished (for SS) | Provides corrosion protection. HDG offers robust protection for outdoor/corrosive environments. |

| Design Standard Compliance | ANSI/MSS SP-58, MSS SP-69, ASME B31.1, ASME B31.3 | Ensures the hanger is designed, manufactured, and tested according to recognized international engineering standards. |

| Rod Diameter | 3/8" to 2-1/2" | The diameter of the threaded suspension rod, directly related to the hanger's load-bearing capacity. |

| Estimated Service Life | 20-40 years (dependent on material and environment) | A projection of operational lifespan under specified conditions, reflecting material quality and manufacturing excellence. |

Manufacturing Excellence: A Transparent Process

The reliability of a Celling Suspended Wire Hanger is a direct result of a meticulous and controlled manufacturing process. We believe in complete transparency, ensuring our clients understand the quality embedded in every component we produce. Our process is certified under ISO 9001:2015, guaranteeing consistency and adherence to the highest quality management standards.

Step 1: Raw Material Selection & Inspection

Sourcing premium-grade steel (Carbon, Stainless, Alloy) from certified mills. Each batch undergoes Spectro analysis and ultrasonic testing to verify chemical composition and internal integrity.

Step 2: Precision Forging / CNC Machining

Components like clevises and eye nuts are hot-forged to align the material's grain structure, enhancing strength and fatigue resistance. Critical dimensions are then finished using multi-axis CNC machines for tolerances within ±0.005 inches.

Step 3: Wire Forming and Threading

The hanger wire/rod is precisely bent to shape using automated equipment. Threads are roll-threaded, not cut, which work-hardens the surface for increased strength and resistance to stripping.

Step 4: Heat Treatment & Surface Finishing

Components may undergo quenching and tempering to achieve the desired hardness and ductility. Subsequently, they are finished with Hot-Dip Galvanization (per ASTM A153) or other specified coatings for corrosion protection.

Step 5: Rigorous Quality Control & Testing

Final products undergo a battery of tests: Load Testing (to 2.5x rated capacity), Magnetic Particle Inspection (MPI) for surface defects, and dimensional verification. Each hanger is stamped with a heat number for full traceability.

Step 6: Assembly & Secure Packaging

Components are assembled, quality-checked one last time, and securely packaged with protective materials to prevent damage during shipping and handling. Each package includes a test certificate and installation guide.

Technical Advantages & Performance Visualization

Our Celling Suspended Wire Hanger is not just a piece of hardware; it's an engineered solution providing tangible benefits. These advantages translate directly into enhanced safety, reduced maintenance costs, and improved plant longevity.

- Superior Load Bearing Capacity: Engineered with a 5:1 safety factor, our hangers exceed industry standards, providing a robust safety margin for dynamic loads and unforeseen stresses.

- Exceptional Corrosion Resistance: With options like SS316L and Hot-Dip Galvanization exceeding 85 microns thickness, our hangers are built to withstand the most aggressive chemical and saline environments, ensuring decades of service life.

- Accommodation of Thermal Movement: The design inherently allows for axial and transverse pipe movement due to thermal expansion and contraction, preventing stress build-up in the piping system and at connection points.

- Vibration Dampening: The inherent flexibility of the wire form, combined with optional vibration-dampening pads, effectively reduces the transmission of mechanical vibration, protecting both the pipe and the support structure.

- Full Traceability and Compliance: Every hanger is marked with a unique heat number and material grade, providing full traceability back to the raw material certificate, ensuring 100% compliance with project specifications and standards like ASME B31.3.

- Simplified Installation and Adjustment: Featuring precision-rolled threads and robust hex nuts, our hangers allow for easy vertical adjustment post-installation, saving significant time and labor during commissioning.

Application Industry Distribution

Legend: ■ 40% Petrochemical, ■ 30% Metallurgy, ■ 20% Water Treatment, ■ 10% Other.

This chart reflects the primary industries relying on high-performance Celling Suspended Wire Hanger systems, underscoring their importance in critical infrastructure.

Load Capacity vs. Temperature

Illustrates the de-rating of a standard carbon steel hanger's load capacity at elevated temperatures, highlighting the need for alloy materials in high-heat applications.

Manufacturer Comparison: Why Choose Us?

In a market with numerous suppliers, discerning quality can be challenging. A direct comparison reveals the substantial differences between a standard, off-the-shelf product and our precision-engineered Celling Suspended Wire Hanger.

| Feature / Attribute | CNTC Metal (Our Brand) | Generic Competitor |

|---|---|---|

| Material Certification | EN 10204 3.1 Certificate for every batch | Often unavailable or only basic compliance certificate |

| Load Testing | 100% of batches proof-tested to 2.5x WLL | Spot testing or testing by request only |

| Standard Compliance | Guaranteed compliance with MSS SP-58 & ASME B31.1 | May claim compliance without rigorous verification |

| Thread Manufacturing | Rolled threads for superior strength | Cut threads, which are weaker and prone to stripping |

| Corrosion Protection (HDG) | Average thickness >85 µm (ASTM A153) | Thinner, less consistent coating (~45-60 µm) |

| Traceability | Full traceability via heat number stamping | Limited or no traceability |

| Customization Capability | ✔ | ✖ |

| Technical Support | Expert engineering support for selection & design | Basic sales support |

Customization and Engineered Solutions

Standard sizes don't always fit unique challenges. We specialize in providing bespoke Celling Suspended Wire Hanger solutions tailored to your project's specific requirements. Our engineering team collaborates with you to develop hangers for non-standard pipe sizes, extreme temperature or load conditions, unusual structural attachments, or unique material requirements.

Our Customization Process:

- Consultation: We begin with a detailed discussion of your application, including P&IDs, isometric drawings, and environmental conditions.

- Design & Analysis: Using advanced CAD and FEA software, we model a custom hanger design, performing stress analysis to validate its performance under your specified loads.

- Material Selection: We recommend the optimal material, from Duplex Stainless Steel for high-chloride environments to Chrome-Moly alloys for high-temperature service.

- Prototype & Testing: For critical applications, we can produce and rigorously test a prototype to confirm all performance criteria are met before full production.

- Manufacturing & Delivery: Upon approval, we manufacture your custom hangers under our stringent ISO 9001 quality system, ensuring they meet your exact specifications.

Whether you need modified dimensions, special coatings, or a completely new design, our team has the expertise to deliver a reliable and cost-effective solution.

Request a Custom Solution QuoteApplication Cases & Real-World Experience

The true measure of a product's value is its performance in the field. Our Celling Suspended Wire Hanger systems are trusted by leading companies across various demanding industries. This experience demonstrates our deep understanding of real-world operational challenges.

Case Study 1: Petrochemical Refinery Expansion

Client: Major Middle East Oil & Gas Company

Challenge: Supporting high-temperature (550°C) process piping in a highly corrosive, saline coastal environment. The existing supports were failing prematurely due to creep and corrosion.

Solution: We provided custom Celling Suspended Wire Hanger systems fabricated from ASTM A387 Grade 11 Alloy Steel (Chrome-Moly) for high-temperature strength, with a specialized multi-layer epoxy coating over galvanization for dual-barrier corrosion protection.

Result: Achieved a 300% increase in support lifespan, significantly reduced maintenance cycles, and ensured the integrity of critical process lines, preventing costly unplanned shutdowns. The project was completed ahead of schedule due to the ease of installation and adjustment.

Case Study 2: Integrated Steel Mill Modernization

Client: European Steel Manufacturing Leader

Challenge: Supporting large-diameter (24") cooling water pipelines subject to heavy vibration from adjacent rolling mills.

Solution: We supplied heavy-duty Celling Suspended Wire Hanger units made from high-strength carbon steel, integrated with custom-designed neoprene vibration isolation pads.

Result: Vibration transmission to the support structure was reduced by over 85%, mitigating fatigue risk to both the pipeline and the building's steel frame. The client reported a quieter and safer operating environment.

"The technical support from CNTC Metal was exceptional. They didn't just sell us a product; they provided an engineered solution. The quality and traceability of their Celling Suspended Wire Hanger gave our safety and inspection teams complete confidence. We've now specified them as the standard for all future projects."

- Lead Piping Engineer, Global EPC Contractor

Frequently Asked Questions (FAQ)

Our experts answer your most common technical questions about the Celling Suspended Wire Hanger.

1. What is the difference between SS304 and SS316 stainless steel, and which should I choose?

The primary difference is the addition of molybdenum (about 2-3%) in SS316. This gives it significantly enhanced resistance to corrosion, especially from chlorides and other industrial acids. Rule of thumb: Use SS304 for general atmospheric and mild corrosive environments (e.g., food processing, freshwater systems). Use SS316 for marine environments, coastal areas, chemical processing plants, and wastewater treatment facilities where chloride exposure is high.

2. How do I determine the correct load capacity for my Celling Suspended Wire Hanger?

The load calculation must account for several factors: the weight of the pipe, the weight of the fluid or medium it carries, the weight of insulation, the weight of any inline components (valves, flanges), and potential snow/ice loads for outdoor pipes. The total weight is then divided by the number of hangers on a span. Always consult engineering standards like ASME B31.1 and apply a safety factor (typically 3:1 to 5:1) to the calculated load to select the appropriate hanger.

3. What does "compliance with MSS SP-58" actually mean?

MSS SP-58, published by the Manufacturers Standardization Society, is the industry's cornerstone standard for "Pipe Hangers and Supports - Materials, Design, Manufacture, Selection, Application, and Installation." Compliance means the Celling Suspended Wire Hanger is designed and built according to the minimum material requirements, dimensional standards, and load ratings specified in this document, ensuring a baseline of quality and interoperability.

4. Can I use a standard carbon steel hanger for a high-temperature steam line?

It depends on the temperature. Standard carbon steel (like ASTM A36) begins to lose significant strength (a process called "creep") at temperatures above 400°C (750°F). For high-temperature steam, process fluids, or exhaust, you must use a chrome-molybdenum (Chrome-Moly) alloy steel hanger (e.g., ASTM A387) designed specifically for elevated temperatures to ensure long-term safety and reliability.

5. What is the advantage of Hot-Dip Galvanization (HDG) over Electro-Galvanization?

HDG involves immersing the steel parts in a bath of molten zinc, creating a thick, metallurgically bonded alloy coating that is highly durable and abrasion-resistant. It provides superior, long-lasting corrosion protection for outdoor and harsh environments. Electro-galvanization provides a very thin, cosmetic layer of zinc that offers only minimal protection and is suitable only for dry, indoor environments.

6. What is the typical delivery cycle for standard and custom orders?

For standard, in-stock Celling Suspended Wire Hanger models, our typical delivery time is within 5-7 business days. For custom-engineered solutions, the cycle depends on complexity. A typical timeline is 1-2 weeks for design and approval, followed by 3-5 weeks for manufacturing and testing. We provide a detailed project timeline upon quotation.

7. What is your warranty and quality assurance promise?

We stand behind our products with a comprehensive 5-year manufacturer's warranty against defects in materials and workmanship. Our quality assurance is built on our ISO 9001:2015 certified process, which includes 100% material traceability, certified material test reports (MTRs), and proof load testing documentation for every batch of Celling Suspended Wire Hanger we ship.

Your Partner in Industrial Piping Integrity

Choosing the right Celling Suspended Wire Hanger is a critical decision that impacts the safety, efficiency, and longevity of your entire piping infrastructure. By prioritizing certified materials, precision manufacturing, and adherence to stringent international standards, we provide more than just a component; we deliver peace of mind. Our commitment to expertise, demonstrated experience, and unwavering trustworthiness makes us the ideal partner for your most demanding projects.

Ready to elevate the standard of your piping support systems? Contact our engineering team today to discuss your specific needs or to request a detailed quote.

References and Further Reading:

1. ASME B31.1 - Power Piping: An essential code for the design, material, fabrication, erection, test, and inspection of power piping systems. Provides context for hanger selection and spacing. View Standard.

2. Eng-Tips Forums - Pipe Hanger Design & Issues: A professional forum where engineers discuss real-world challenges and solutions related to pipe supports, including material selection in corrosive environments. Visit Forum.

3. Manufacturers Standardization Society (MSS) SP-58: The definitive standard for pipe hanger materials, design, and manufacturing, referenced throughout this guide. Learn more at MSS HQ.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025