- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Optimizing Performance of Steel Extension Springs for Enhanced Durability and Functionality

Understanding Steel Extension Springs Their Design and Applications

Steel extension springs are a type of mechanical spring that exerts an outward force when stretched. They are commonly made of steel, which is prized for its strength, durability, and ability to withstand substantial amounts of tension without deforming. Extension springs are found in a multitude of applications, ranging from everyday household items to complex machinery, highlighting their versatility and importance in engineering.

Design and Features

The design of a steel extension spring is defined by several key characteristics wire diameter, coil diameter, total length, and the number of active coils. The wire diameter affects the spring's strength and flexibility; a thicker wire will provide more resistance to deformation, while a thinner wire allows for greater stretch. Coil diameter is also critical, as it impacts the spring's ability to fit within a designated space while maintaining effectiveness.

Another essential feature of extension springs is their end hooks, which allow them to be anchored to other components. These hooks can be designed in various styles depending on the specific application, enabling a secure connection that optimizes the spring's tension.

Manufacturing Process

The production of steel extension springs begins with the selection of high-quality steel wire. Typical materials include stainless steel, music wire, and oil-tempered wire, each offering unique properties such as corrosion resistance or enhanced elasticity. The manufacturing process usually includes several steps

1. Wire Drawing This involves reducing the diameter of the wire through a series of dies to achieve the desired thickness. 2. Coiling The wire is then shaped into coils using spring coiling machines, which create the desired coil diameter and number of coils.

3. Heat Treatment To enhance the spring's mechanical properties, it undergoes heat treatment, which increases its strength by altering the microstructure of the steel.

4. Finishing The final steps often include shot peening, surface cleaning, and, in some cases, coating to improve corrosion resistance and aesthetics.

Applications

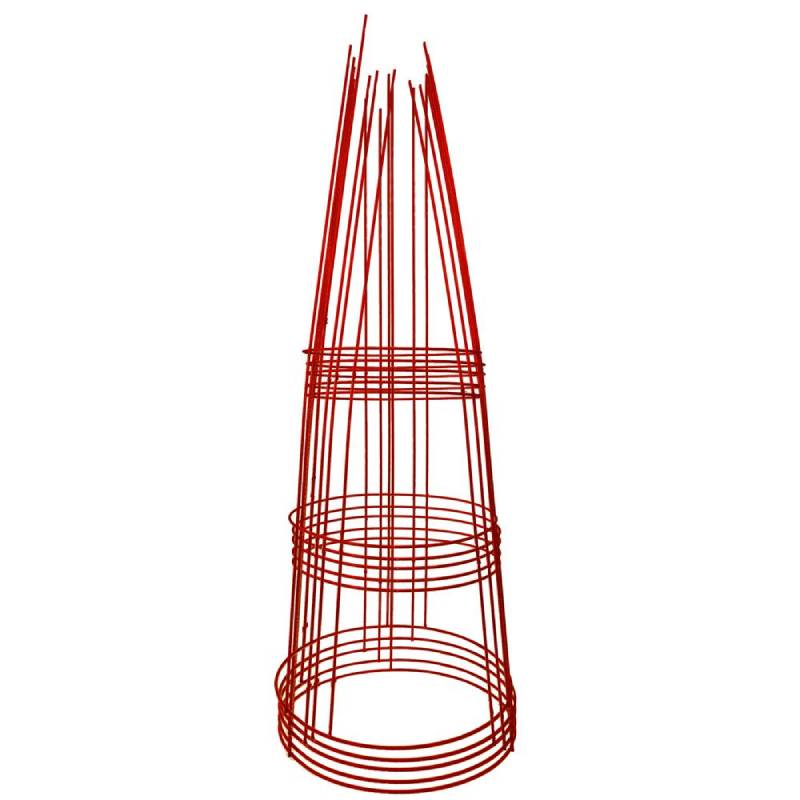

steel extension spring

The applications of steel extension springs are vast and varied

. They are extensively used in- Automotive Industry Extension springs can be found in various automotive components, such as door latches, hoods, and trunk release mechanisms, where reliable tension is necessary for operation.

- Industrial Machinery In manufacturing equipment, extension springs are vital in maintaining tension for moving parts, ensuring smooth and safe operation.

- Household Products Common items like window blinds, toys, and various kitchen gadgets utilize extension springs due to their reliability and compact nature.

- Aerospace In the aviation industry, these springs are critical in landing gear and various control mechanisms, where they must perform under extreme conditions.

Advantages of Steel Extension Springs

Steel extension springs offer numerous advantages, making them a popular choice in various engineering applications. Their strength-to-weight ratio allows them to provide significant force while remaining lightweight. Additionally, they can withstand considerable cyclic loading, making them ideal for repetitive use in machinery.

Moreover, their adaptability means that manufacturers can tailor them to specific requirements, optimizing performance across different applications. Features like custom lengths, finishes, and coil designs enable the production of springs that meet unique demands.

Conclusion

In summary, steel extension springs are essential components in numerous applications, providing reliable and lasting tension in mechanical systems. Their thoughtful design, extensive manufacturing process, and versatility make them a staple in diverse industries. As technology continues to evolve, the role of extension springs may expand, incorporating advanced materials and manufacturing techniques that further enhance their functionality and application scope. Understanding the fundamentals of steel extension springs highlights their critical place in engineering and everyday life.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025