- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

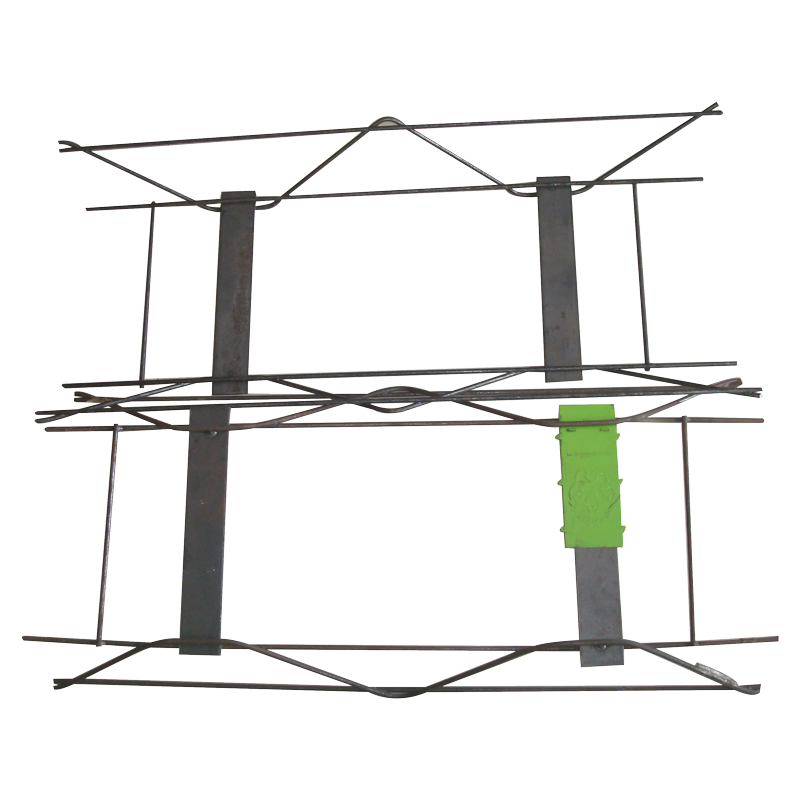

types of cavity wall ties

Types of Cavity Wall Ties

Cavity walls are a popular choice in modern construction due to their thermal efficiency, moisture resistance, and structural stability. A crucial component of these walls is the wall tie, which connects the two leaves (inner and outer) of the cavity wall, helping to maintain the overall integrity and stability of the structure. This article explores the various types of cavity wall ties, their materials, and applications.

1. Stainless Steel Wall Ties

Stainless steel wall ties are commonly used due to their durability and resistance to corrosion. Available in various grades, such as 304 and 316, these ties can withstand harsh environmental conditions. They are ideal for coastal areas where salt spray could lead to corrosion in other materials. The durability of stainless steel ensures a long lifespan, making it a preferred choice for many builders.

Galvanized steel ties are coated with zinc to enhance resistance to rust and corrosion. Although they are less expensive than stainless steel, their longevity is generally lower, especially in aggressive environments. Galvanized ties are suitable for many general-purpose applications in cavity walls, particularly where the conditions are not excessively harsh. They provide good strength and are commonly used in residential construction.

3. Plastic Wall Ties

Plastic wall ties are an innovative alternative that provides excellent moisture resistance, making them suitable for structures exposed to damp conditions. They are lightweight and easy to handle, but their strength is often less than that of metal ties. These ties are ideal for certain applications where moisture control is critical, such as in homes with significant insulation requirements. Many plastic wall ties are also designed to meet specific building standards and are often employed in energy-efficient designs.

types of cavity wall ties

4. Composite Wall Ties

Composite wall ties are made from a combination of materials, often incorporating both metal and plastic. They are designed to deliver the advantages of both materials, such as corrosion resistance paired with lightweight properties. Composite ties can minimize thermal bridging, which can help improve the overall energy efficiency of the building envelope. These ties are especially suitable for modern constructions that emphasize insulation and sustainability.

5. Restraint Wall Ties

Restraint wall ties are a specific type of tie designed to resist lateral movements. These ties are used primarily in situations where the stability of the cavity wall needs to be enhanced, such as in taller structures or in areas prone to high wind loads. They provide additional support and are crucial in ensuring that the inner leaf remains securely attached to the outer leaf, thereby maintaining the wall's structural integrity.

6. Adjustable Wall Ties

Adjustable wall ties are designed with flexibility in length and positioning, allowing for easy installation in varying wall thicknesses. They are especially useful in retrofitting projects where existing dimensions may not conform to standard tie lengths. Adjustable ties help accommodate structural changes and ensure that builders can meet specific design requirements without compromising structural integrity.

Conclusion

Choosing the right type of cavity wall tie is essential for ensuring the structural soundness and longevity of cavity walls. Factors such as environmental conditions, moisture exposure, and the specific demands of the construction project must be considered when selecting wall ties. Understanding the various types available—ranging from stainless steel and galvanized steel to plastic, composite, restraint, and adjustable wall ties—enables builders and contractors to make informed decisions that contribute to the overall performance and sustainability of their buildings. As construction practices evolve, the development of new materials and technologies will continue to enhance the effectiveness of cavity wall ties, making them an essential component of modern architecture.

share:

-

creative-ways-to-decorate-your-tomato-cageNewsAug.22,2025

-

common-mistakes-when-installing-brick-wall-tiesNewsAug.22,2025

-

customizing-conical-springs-for-aerospace-applicationsNewsAug.22,2025

-

galvanized-tie-wire-for-binding-pipesNewsAug.22,2025

-

environmental-impact-of-using-snake-spacers-in-plumbingNewsAug.22,2025

-

sacrificial-formwork-systems-for-complex-structuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025