- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Exploring the Benefits and Applications of Tiny Compression Springs in Modern Engineering

Understanding Tiny Compression Springs Applications and Benefits

Tiny compression springs, though small in size, play a crucial role in various mechanical systems and everyday devices. These springs are designed to resist compression and return to their original shape when the compressive force is removed. Their unique characteristics make them indispensable in numerous applications across different industries.

What Are Tiny Compression Springs?

Compression springs are helical springs that are tightly wound and designed to compress under an external load. Tiny compression springs are specifically classified based on their size, usually having a smaller diameter and length compared to standard compression springs. Despite their diminutive stature, these springs are engineered to provide significant force exertion, making them suitable for applications where space is at a premium.

Applications of Tiny Compression Springs

1. Electronics In the electronics sector, tiny compression springs are commonly used in devices like switches, circuit breakers, and connectors. They help in maintaining contact pressure and ensuring that circuits operate effectively. The reliability of these springs in maintaining consistent force over time is critical, especially in sensitive electronic equipment.

2. Medical Devices Tiny compression springs are vital components in various medical devices. For instance, they are found in syringes, surgical instruments, and other equipment that requires precise mechanical movements. The ability of these springs to withstand repeated compressive forces without losing their mechanical integrity is essential for the accuracy and reliability of medical devices.

3. Automotive Applications Many automotive components, such as door latches and gear shifters, utilize tiny compression springs. They help in providing the needed return force, ensuring that parts function smoothly and efficiently. Their resilience and compact design make them perfect for fitting into the intricate mechanisms found in modern vehicles.

4. Consumer Products Numerous everyday products, from pens and toys to kitchen gadgets, incorporate tiny compression springs. These springs help in creating the push-button mechanisms that are ubiquitous in consumer electronics and toys, allowing for smooth and reliable operation.

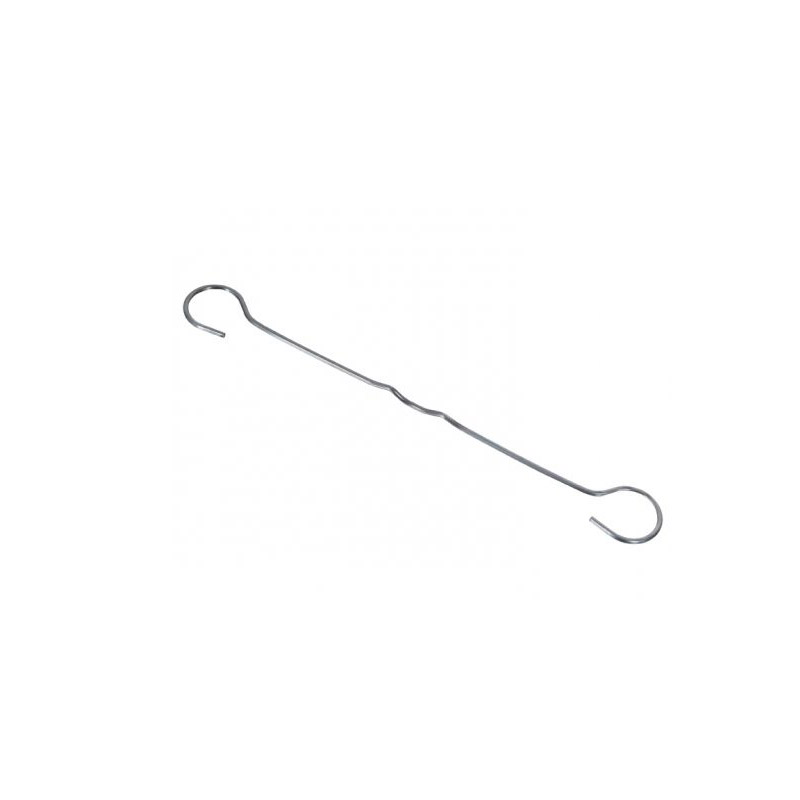

tiny compression spring

5. Aerospace In the aerospace industry, lightweight and compact components are critical. Tiny compression springs are used in various applications, including landing gear mechanisms and control surfaces. Their ability to perform in high-stress and variable environments makes them suitable for aerospace applications, where reliability is paramount.

Advantages of Tiny Compression Springs

1. Space Efficiency The most evident advantage of tiny compression springs is their size. Manufacturers are continuously searching for ways to optimize space within their products, and tiny compression springs contribute significantly to minimizing overall dimensions while still providing the necessary functionality.

2. High Load Capacity Despite their small size, these springs can bear substantial loads relative to their dimensions. This capability allows designers and engineers to use them in applications that require a high strength-to-weight ratio.

3. Durability Tiny compression springs are made from high-quality materials such as stainless steel and various alloys, ensuring they can withstand repeated compression cycles. This durability translates into extended lifespans for the devices they are incorporated into, reducing maintenance costs and improving reliability.

4. Versatility The applications for tiny compression springs are extensive, making them versatile components in countless designs. Their adaptability to different environments and conditions means they can be customized for specific needs across various industries.

Conclusion

Tiny compression springs, while often overlooked due to their size, are integral to the functionality of many devices we encounter in our daily lives. From high-tech electronics to simple household items, their presence is vital for efficient operation. Understanding their applications and advantages helps highlight the importance of these small but mighty components. As technology continues to advance and the demand for compact and efficient design grows, the role of tiny compression springs will undoubtedly become even more significant in the years to come.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025