- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

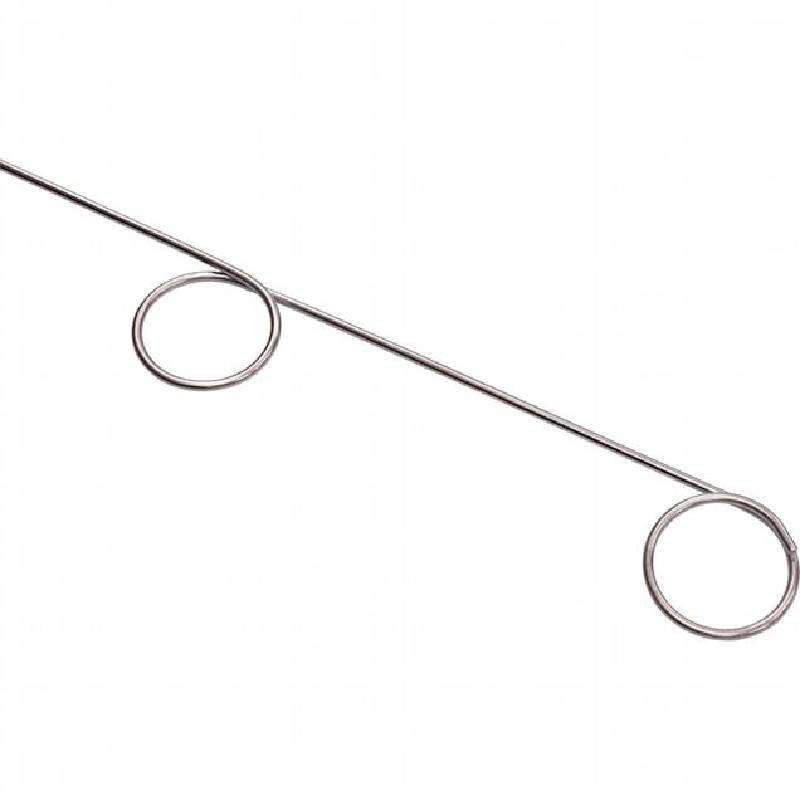

round wire springs

Understanding Round Wire Springs Design, Applications, and Manufacturing

Round wire springs are one of the most fundamental types of springs used in various applications across multiple industries. Their design, functionality, and versatility make them a critical component in mechanical systems, from everyday household items to complex industrial machinery. This article delves into the characteristics, applications, and manufacturing processes associated with round wire springs.

What are Round Wire Springs?

A round wire spring is crafted from wire that is uniformly cylindrical in shape. The wire's diameter can vary based on the spring's design and intended use. These springs are often coiled into various shapes to serve specific functions, such as compression, tension, or torsion, reflecting the nature of the forces they will encounter during operation.

The simplest form of a round wire spring is the helical spring. Helical springs are created by winding the wire into a coil shape. When force is applied, the spring either compresses or stretches, storing mechanical energy in the process. The material and diameter of the wire, as well as the number of coils, determine the spring's properties, such as its stiffness and load-bearing capacity.

Materials Used in Round Wire Springs

Round wire springs can be manufactured from a variety of materials, each selected for its unique properties. Common materials include

1. Steel Carbon steel and stainless steel are frequently used due to their excellent tensile strength and fatigue resistance. Stainless steel is particularly valuable in environments that are susceptible to corrosion.

2. Alloys Certain alloys, such as music wire, offer enhanced elasticity and fatigue resistance, making them ideal for high-performance applications.

3. Plastic In specialized conditions where metal springs may corrode or weigh too much, plastic springs provide a lightweight and non-corrosive alternative.

Applications of Round Wire Springs

Round wire springs find extensive applications across numerous fields

round wire springs

1. Automotive Used in suspensions, clutch mechanisms, and various other components, round wire springs play a vital role in enhancing vehicle performance and safety.

2. Electronics These springs serve in various electronic devices such as keyboards, remote controls, and circuit boards, where they help in maintaining contact integrity and providing tactile feedback.

3. Manufacturing In automation and assembly processes, round wire springs are used in fixtures, tools, and machinery to provide reliable force and positioning.

4. Consumer Products From ballpoint pens to kitchen appliances, these springs are omnipresent in many household items, showcasing their versatility and importance in product design.

Manufacturing Processes

The manufacturing of round wire springs involves a series of precise steps aimed at achieving the desired specifications. The general process includes

1. Wire Drawing The initial step is the production of wire by drawing it through progressively smaller dies to reach the required diameter.

2. Coiling The drawn wire is then coiled into the desired shape using specialized machines. This step often requires advanced techniques to ensure accuracy in coil tension and spacing.

3. Heat Treatment To improve mechanical properties, most springs undergo heat treatment. This process can relieve stresses and enhance the spring's overall strength and elasticity.

4. Finishing Finally, springs may receive a variety of surface treatments, such as plating or coating, to enhance corrosion resistance and aesthetic appeal.

Conclusion

Round wire springs are an essential element in various industries, defined by their simple yet effective design. Their adaptability to different materials, configurations, and applications underscores their value in modern engineering and manufacturing. Understanding the nature of round wire springs not only helps in selecting the right spring for a given application but also emphasizes their role in enhancing the functionality and reliability of countless products and systems. As technology continues to evolve, the design and application of round wire springs are likely to adapt, opening new avenues for innovation in the future.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025