- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

high tensile springs

High Tensile Springs The Backbone of Modern Engineering

High tensile springs play a crucial role in various industries, serving as essential components in a wide array of applications, from automotive systems to industrial machinery. Their strength and resilience make them indispensable in scenarios where maximum load-bearing capacity is required. This article explores the significance, types, and applications of high tensile springs, along with their manufacturing processes and factors influencing their performance.

Understanding High Tensile Springs

High tensile springs are made from materials that possess high tensile strength, which enables them to withstand significant forces and deformations without failing. These springs are typically crafted from specialized steel alloys, such as stainless steel, music wire, and high-carbon steel. The selection of the material is crucial, as it impacts the spring's durability, flexibility, and ability to return to its original shape after loading.

There are various types of high tensile springs, including compression springs, extension springs, and torsion springs. Compression springs are designed to resist compressive forces and are often found in applications such as automotive suspensions and industrial machinery. Extension springs, on the other hand, are used to absorb and store energy when stretched, making them vital in applications ranging from door closing mechanisms to trampoline springs. Torsion springs work by applying torque and can be found in devices such as clothespins and seatbelt retractors.

Applications Across Industries

The versatility of high tensile springs allows them to be used across numerous sectors. In the automotive industry, they contribute to vehicle safety and comfort systems, enabling features like shock absorption and suspension support. In the aerospace sector, high tensile springs are employed to ensure the integrity of various systems, including landing gear mechanisms and control surfaces. Additionally, they are crucial in the manufacturing of appliances, electronics, and medical equipment.

high tensile springs

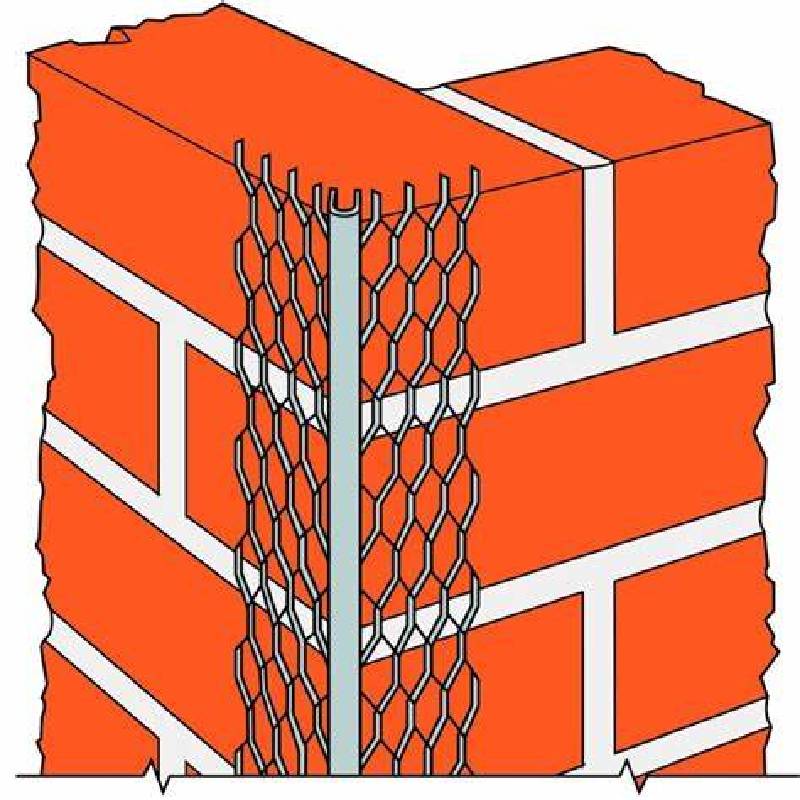

High tensile springs also find their place in the construction field. They are often utilized in heavy machinery and structures, supporting loads and enhancing structural integrity. Moreover, industries such as telecommunications and robotics rely on these springs for precision and reliability in their operations.

Manufacturing and Quality Control

The manufacturing of high tensile springs involves several key processes, including wire drawing, coiling, heat treatment, and surface finishing. Wire drawing shapes raw materials into the desired wire diameter, which is then coiled into a spring form. Heat treatment is often applied to enhance the mechanical properties of the spring, allowing it to endure higher stress levels. Surface finishing processes, such as coating or plating, may also be implemented to protect the springs from corrosion and wear.

Quality control is paramount in the production of high tensile springs, as even minor defects can compromise their performance. Various tests, including tensile strength tests, fatigue tests, and dimensional inspections, are conducted to ensure that the springs meet the stringent requirements of their intended applications.

Factors Influencing Performance

Several factors influence the performance and longevity of high tensile springs. Material selection, environmental conditions, and manufacturing techniques all play a role in how well a spring performs under load. For instance, exposure to extreme temperatures or corrosive environments can deteriorate spring materials, leading to premature failure. Therefore, it's essential to choose the right type of spring for the specific application and operating conditions.

In conclusion, high tensile springs are vital components that support various industries by providing strength, flexibility, and reliability. Their extensive applications and the advanced technology used in their manufacturing underscore their importance in modern engineering. As industries continue to evolve, the demand for high-performance springs will likely grow, pushing manufacturers to innovate and enhance the properties of high tensile springs even further.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025