- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

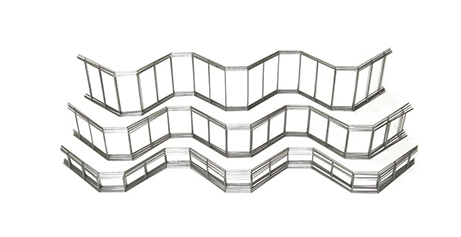

double coil spring

Understanding Double Coil Springs Basics and Applications

Double coil springs are vital mechanical components widely used in various applications, from automotive to industrial machinery. These springs, characterized by their two intertwined coils, provide enhanced performance and durability compared to single coil springs. This article delves into the fundamental aspects of double coil springs, their design, advantages, and applications.

Design and Construction

Double coil springs are formed by coiling wire into two spirals that run parallel to each other. This design allows for greater elasticity and load-bearing capacity. The coils are usually made from high-carbon steel or stainless steel to enhance their strength and fatigue resistance. The double coil configuration means that the spring can handle larger loads and return to its original shape more effectively after being compressed or stretched.

One of the key features of double coil springs is their ability to distribute load evenly across both coils. This not only contributes to their longevity but also reduces the risk of deformation under heavy loads. The spring's dimensions, including coil diameter, wire thickness, and overall length, can be customized based on the specific requirements of an application.

Advantages of Double Coil Springs

The primary advantage of double coil springs lies in their improved resilience. They can withstand larger compressive and tensile forces without suffering from permanent deformation. Additionally, the dual coils can absorb shocks and vibrations more effectively than single springs, making them ideal for applications requiring stability and dampening.

double coil spring

Another significant benefit is the increased surface area provided by the two coils. This larger surface area enhances heat dissipation during operation, preventing overheating and prolonging the life of the spring. Double coil springs also offer better fatigue resistance, meaning they can endure repeated loading cycles over extended periods without breaking down.

Applications of Double Coil Springs

Due to their robust design and reliable performance, double coil springs find applications in numerous industries. In the automotive sector, they are commonly used in suspension systems, where they help absorb shocks from the road, ensuring a smoother ride. They also play a crucial role in the operation of engines, pumps, and various mechanical devices where consistent force and resistance are required.

In the industrial realm, double coil springs are utilized in equipment such as conveyor belts, machinery, and even in electronic devices where precise movement and stability are critical. Their ability to handle large loads and resist wear makes them invaluable in environments that demand durability and reliability.

Conclusion

In summary, double coil springs are essential components in modern engineering and manufacturing, offering superior strength, flexibility, and longevity. Their unique design allows for enhanced performance in a variety of applications, making them an indispensable part of many mechanical systems. As industries continue to evolve, the demand for such resilient springs will undoubtedly grow, paving the way for innovations that further optimize their design and functionality. Whether in automotive, industrial, or consumer products, understanding the significance of double coil springs is crucial for harnessing their full potential.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025