- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Factors Influencing the Cost of Welded Wire Fabric in Construction Applications

The Cost of Welded Wire Fabric An Overview

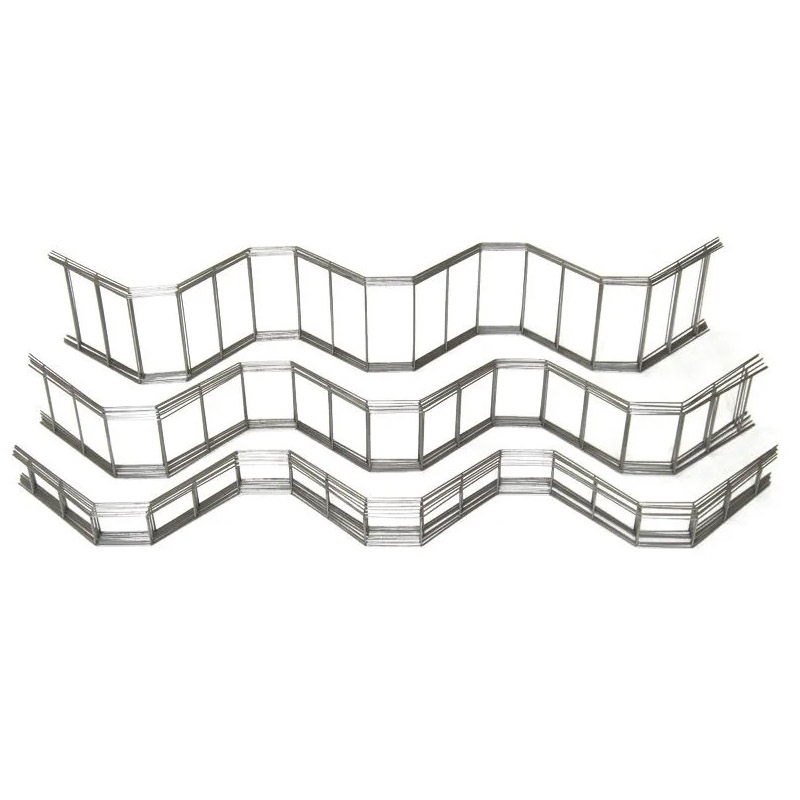

Welded wire fabric, also known as welded wire mesh, is an essential component in a wide range of construction and engineering applications. Its versatility, strength, and cost-effectiveness make it a preferred choice for reinforcing concrete structures, providing support in various construction projects. However, understanding the cost associated with welded wire fabric is crucial for project budgeting and material selection.

The cost of welded wire fabric can vary significantly based on several factors. Key considerations include the gauge of the wire, the spacing of the wires, and the overall size of the sheets or rolls. Thicker wires or closer spacing generally increase the material's strength and durability but also lead to higher costs. For instance, standard wire gauges, such as 6, 8, or 10 gauge, are commonly used, and as the gauge number decreases, the diameter of the wire increases, which again impacts pricing.

Material composition also plays a vital role in the cost structure. Most welded wire fabric is made from carbon steel, but specialty materials such as stainless steel or galvanized wire can significantly raise expenses due to their enhanced corrosion resistance and longevity. Galvanization, in particular, protects the mesh from rust, making it a suitable option for outdoor applications or environments with high moisture levels.

cost of welded wire fabric

Another significant factor affecting the cost is the manufacturing process. Welding the wires together creates a strong intersection point, providing consistent structural integrity. The complexity of this process, coupled with the scale of production, can influence pricing. High-volume production typically leads to lower per-unit costs, which makes bulk purchases a strategic choice for large-scale projects.

Additionally, market fluctuations impact prices. The cost of raw materials, especially steel, can vary due to economic conditions, tariffs, or changes in demand. Therefore, keeping an eye on market trends and sourcing materials when prices are favorable can result in significant savings.

Transportation and logistics also contribute to the overall expense. Since welded wire fabric can be bulky and heavy, shipping costs can add up, especially for projects located in remote areas. It is essential for construction managers to consider these factors when estimating the total cost of welded wire fabric for their projects.

In conclusion, while the initial cost of welded wire fabric might seem straightforward, multiple factors influence its pricing. Understanding these variables allows engineers, architects, and construction managers to make informed decisions that align with their project budgets and timelines. By considering material type, gauge, production volume, and market conditions, stakeholders can effectively manage the costs associated with welded wire fabric, ensuring the efficient allocation of resources in construction projects.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025