- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

conical spring design pdf

Designing Conical Springs Principles and Applications

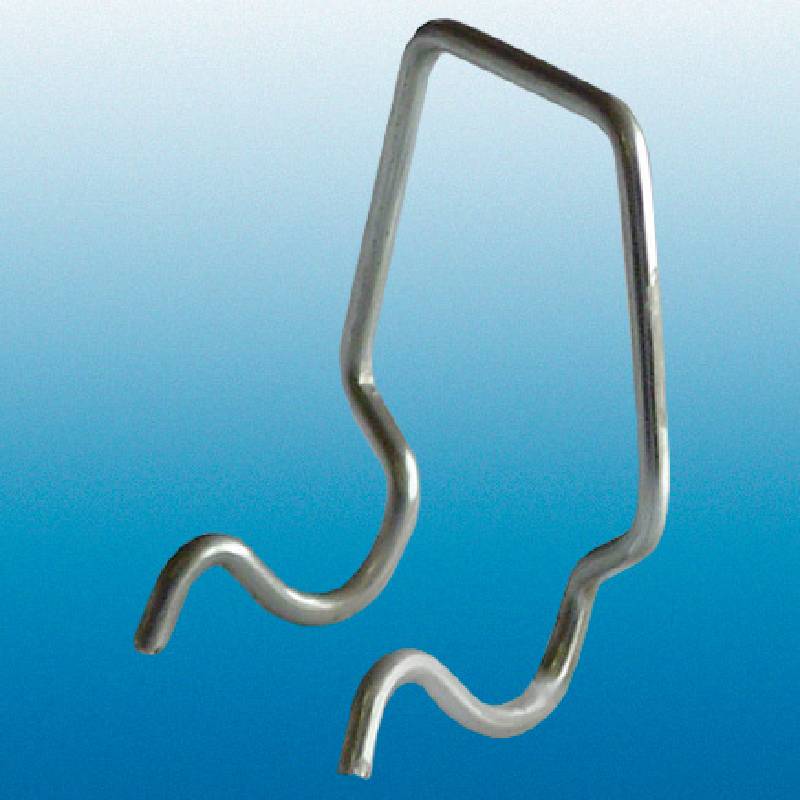

Conical springs are a specialized type of spring that offer unique advantages in various mechanical and structural applications. Unlike traditional cylindrical springs, conical springs have a tapered design that allows for greater flexibility and efficient force distribution. This article explores the principles behind conical spring design, their manufacturing processes, and their applications across different industries.

Principles of Conical Spring Design

The design of a conical spring revolves around several key principles. First and foremost, the geometry of the spring impacts its functional capabilities. Conical springs typically consist of a coil that tapers from a wider end to a narrower end, allowing for a linear or progressive spring action. This design means that the force exerted by the spring can vary depending on the amount of compression or extension, which is achieved by adjusting the coil dimensions.

The spring's material properties are equally crucial. Most conical springs are constructed from high-strength alloys or tempered steel, which provide the necessary resilience and fatigue resistance. The choice of material impacts not only the performance of the spring but also its longevity and reliability under varying operational conditions.

Another essential factor in the design is the spring's load capacity. Engineers must accurately calculate the expected loads the spring will encounter during its service life. This is typically measured in terms of tensile and compressive forces, and the design must accommodate these requirements without failure. Proper design also considers factors like stress concentration and deflection, ensuring that the spring performs within safe operational limits.

Manufacturing Process

The manufacturing process of conical springs involves several steps, starting from material selection to final inspection. The first stage is often raw material preparation, where wire is drawn to the required diameter. Following this, the wire is shaped into coils using specialized machines that can form conical geometries. This involves precise calculations to ensure that the taper is uniform and meets design specifications.

conical spring design pdf

Once the coils are formed, heat treatment may be necessary to enhance material properties. This process involves heating the springs to a high temperature and then quenching them in oil or water to increase strength and elasticity. Finally, surface treatments, such as shot peening or coating, may be applied to reduce wear and corrosion, further extending the lifespan of the spring.

Quality control is a vital aspect of the manufacturing process. Each batch of conical springs undergoes rigorous testing to ensure they meet dimensional and performance criteria. This includes checking for consistency in coil spacing, tolerances, and mechanical properties under load, which ensures reliability in end-use applications.

Applications Across Industries

Conical springs find their applications in diverse fields, including automotive, aerospace, and industrial machinery. In the automotive sector, they are used in suspension systems to provide stability and comfort by absorbing shocks and vibrations. Their unique design allows for a smoother ride while maintaining structural integrity under varying loads.

In aerospace applications, conical springs assist in mechanisms that require precise control and reliability, such as landing gear and control surfaces. The weight-saving properties of these springs are particularly beneficial in this industry, where every ounce counts.

In industrial machinery, conical springs are often employed in assembly lines, packaging equipment, and robotics, where they facilitate movement and provide necessary force without compromising efficiency. Their flexibility and adaptability make them ideal for processes that require variable load support.

Conclusion

The design of conical springs is a complex interplay of engineering principles, material science, and manufacturing precision. Their unique structural attributes offer numerous advantages, allowing them to excel in various applications where traditional springs may fall short. As technology advances, the demand for innovative spring designs like the conical spring continues to grow, making them a crucial component in the future of mechanical design and engineering. Understanding the fundamentals of conical spring design not only enhances their application but also drives further innovations in this vital field.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025