- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

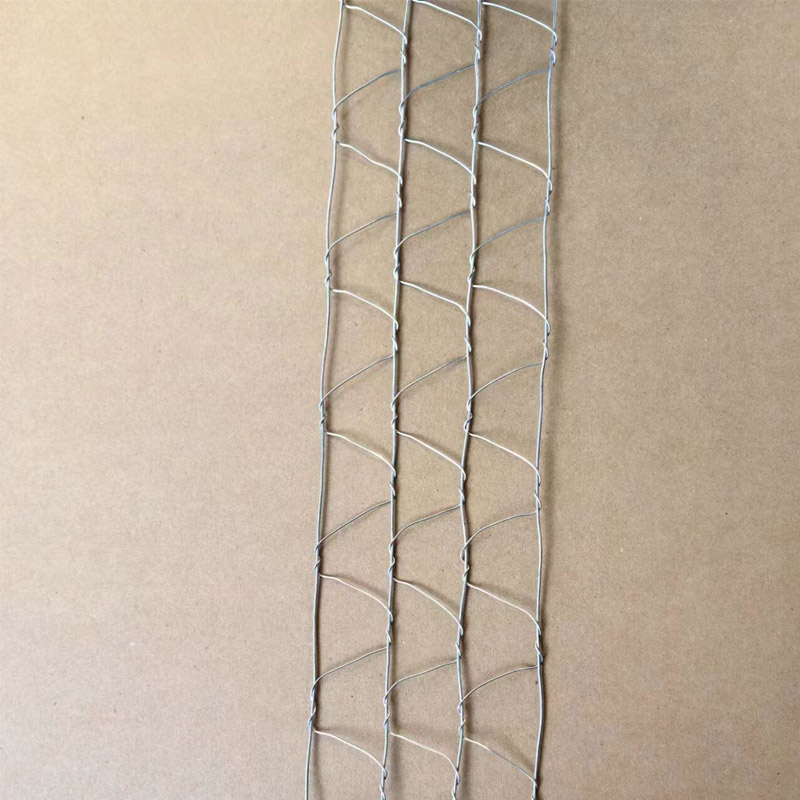

Different Types of Concrete Mesh Used in Construction Applications

Understanding Concrete Mesh Types and Their Applications

Concrete mesh, also known as reinforcement mesh or welded wire mesh, plays a crucial role in the construction industry. It is primarily used to provide structural integrity to concrete structures, ensuring they can withstand various stresses and strains from loads and environmental factors. Understanding the different types of concrete mesh and their applications can greatly enhance the effectiveness of construction projects.

Types of Concrete Mesh

1. Welded Wire Mesh Welded wire mesh is one of the most common types of concrete mesh used in construction. It consists of longitudinal and transverse wires that are welded together at their intersections. This mesh is available in various diameters and spacing patterns, catering to different requirements. Welded wire mesh is particularly known for its tensile strength and rigidity, making it an ideal choice for slabs, pavements, and precast concrete products.

2. Fiberglass Reinforcement Mesh This type of mesh is made from fiberglass, which provides superior resistance to corrosion, making it ideal for use in environments exposed to moisture or chemicals. Fiberglass reinforcement mesh is lightweight, yet strong, making it easier to handle on construction sites. Its application is often seen in pool decks, bridge decks, and in areas where traditional steel mesh would succumb to rust or corrosion.

3. Polypropylene Fiber Mesh Polypropylene fiber mesh incorporates synthetic fibers into concrete, enhancing its resistance to cracking. Unlike welded steel mesh, fiber mesh integrates directly into the concrete mix, offering uniform distribution throughout the structure. This type of mesh is commonly used in slab foundations, pavements, and thin toppings, where it addresses shrinkage cracks and enhances durability without adding significant weight.

4. Bar Mats Bar mats are another form of concrete mesh, where rebar bars are arranged in a grid pattern and are tied together. These mats provide significant tensile strength and stability, making them suitable for heavy-duty applications, such as foundations, large commercial structures, and roads. Bar mats come in various configurations and sizes, tailored to fit the specific load requirements of a project.

5. Expanded Metal Mesh This type of mesh is made by flattening and stretching a metal sheet, creating a grid of openings that can provide additional surface area for bonding with concrete. Expanded metal mesh is often used in exterior applications, including facades and reinforced edges, due to its aesthetic appeal combined with functionality.

Applications of Concrete Mesh

concrete mesh types

Concrete meshes have a wide range of applications in construction, enhancing the structural performance of various concrete elements, such as

- Slabs Concrete slabs benefit significantly from mesh reinforcement

. The mesh provides additional support, reducing the risk of cracking and increasing load-bearing capacity.- Pavements In road construction, concrete mesh is used to improve the durability and longevity of pavement structures, helping them withstand the pressures of traffic and environmental conditions.

- Retaining Walls The use of concrete mesh in retaining walls enhances stability and reduces the likelihood of failure due to soil pressure.

- Precast Concrete Components Many precast elements incorporate wire mesh to ensure uniform strength across panels and elements, improving their performance during installation and throughout their lifespan.

- Structural Repairs When repairing or retrofitting existing structures, concrete mesh can be essential in providing supplemental strength and stability, helping to extend the lifespan of aging buildings and infrastructure.

Conclusion

In summary, concrete mesh is an integral component of modern construction practices, contributing to the strength, durability, and longevity of various concrete elements. With the variety of mesh types available, construction professionals can choose the appropriate reinforcement solution tailored to their specific project requirements. Whether it’s welded wire mesh for slabs or fiberglass mesh for corrosion-prone environments, understanding the implications of each mesh type can lead to better decision-making, ultimately enhancing the overall quality and safety of construction projects. As innovations in material science continue to evolve, we can anticipate new mesh technologies that further improve the resilience and efficiency of concrete structures in the years to come.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025