- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

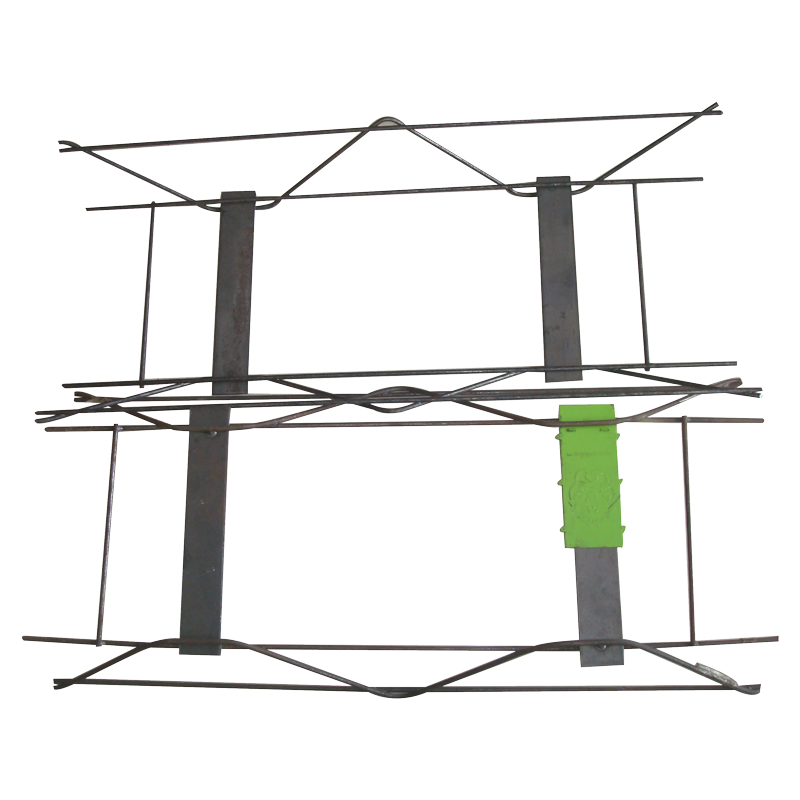

coil spring compression

Understanding Coil Spring Compression Principles and Applications

Coil springs are essential components used in various mechanical systems, playing a critical role in maintaining stability and facilitating movement. A coil spring is an elastic object that can compress or extend under the influence of a load. Its ability to absorb and release energy makes it an indispensable part of automotive suspensions, industrial machinery, and numerous consumer products.

Principles of Coil Spring Compression

The fundamental principle behind coil spring compression lies in Hooke's Law, which states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. Mathematically, this is expressed as

\[ F = k \times x \]

Here, \( F \) represents the force applied to the spring, \( k \) denotes the spring constant (a measure of the spring's stiffness), and \( x \) is the compression or extension from the original length. The spring constant varies depending on the material, diameter, coil thickness, and the number of active coils. A higher spring constant indicates a stiffer spring, requiring more force to achieve the same amount of compression.

When a load is applied to a coil spring, the coils compress, allowing for the potential energy to be stored within the spring. This energy can be released when the force is removed, causing the spring to return to its original shape. This cyclical process of compression and decompression is critical in applications where energy absorption and release play a significant role.

Applications of Coil Springs

coil spring compression

Coil springs are widely used across various industries due to their versatility and effectiveness. One of the most common applications is in automotive vehicles, where they are integral to the suspension system. The coil springs in a car help to absorb shocks from uneven surfaces, ensuring a smooth ride for passengers. When the vehicle goes over a bump, the coil spring compresses, absorbing shock energy and preventing the chassis from hitting the ground.

In industrial settings, coil springs are utilized in machinery to provide support and stability. They are often found in clamping devices, ensuring that parts are held securely during operation. Additionally, they are used in elevators to counterbalance weight, allowing for smoother and more efficient vertical movement.

Consumer products also benefit from coil springs. For example, they are essential components in mattresses, providing comfort and support while allowing for basic movements. Similarly, coil springs are found in pens, helping retract the ink cartridge when not in use.

Design Considerations

When designing coil springs for specific applications, engineers must consider several factors, including the required load capacity, space constraints, and the desired motion characteristics. The material used for the coil spring also plays a crucial role in determining its performance. Common materials include steel, stainless steel, and specialized alloys, each offering varying degrees of elasticity and fatigue resistance.

Conclusion

Coil spring compression is a fundamental concept that underlies the functionality of numerous mechanical devices. Understanding the mechanics of coil springs helps engineers design safer, more efficient systems across industries. As technology evolves, the importance of these springs continues to grow, further emphasizing their crucial role in modern engineering practices. With continuous advancements in materials and design techniques, coil springs will undoubtedly remain a vital component in various applications for years to come.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025