- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Ene . 31, 2025 05:58

Back to list

PVC Coated Welded Mesh

Navigating the world of stainless steel wire mesh specifications can be daunting. As an integral component in a myriad of industrial applications, the clarity and reliability of its specifications are paramount to ensuring efficacy and safety. Here, we delve into key considerations when evaluating stainless steel wire mesh and emphasize the crucial aspects that contribute to its robustness and performance.

Additionally, the weave type plays a significant role in the wire mesh's performance capabilities. The most common types are plain weave and twilled weave. Plain weave is the simplest and most cost-effective, suitable for applications where high strength is not the primary requirement. Twilled weave, however, offers better stability and strength, necessary for heavy-duty applications or when the mesh must accommodate higher mechanical loads. For enhanced credibility and trust, ensuring that the wire mesh specifications align with industry standards is indispensable. Professional organizations such as ASTM International and the International Organization for Standardization (ISO) publish guidelines for mesh specifications. Complying with these standards not only guarantees product reliability but also affirms the manufacturer's commitment to quality and safety. Additionally, obtaining certifications from reputable third-party bodies further enhances confidence, offering assurance that the stainless steel wire mesh products meet stringent quality checks and performance benchmarks. Customers, especially from high-stakes industries, value these certifications as they significantly reduce the risks associated with component failure. In conclusion, understanding and specifying the right stainless steel wire mesh requires a balanced consideration of material grades, mesh count, wire diameter, weave type, and adherence to industry standards. By applying these criteria with expertise and authority, businesses can ensure that their selections meet the demands of their applications effectively, enhancing product performance while safeguarding operational integrity.

Additionally, the weave type plays a significant role in the wire mesh's performance capabilities. The most common types are plain weave and twilled weave. Plain weave is the simplest and most cost-effective, suitable for applications where high strength is not the primary requirement. Twilled weave, however, offers better stability and strength, necessary for heavy-duty applications or when the mesh must accommodate higher mechanical loads. For enhanced credibility and trust, ensuring that the wire mesh specifications align with industry standards is indispensable. Professional organizations such as ASTM International and the International Organization for Standardization (ISO) publish guidelines for mesh specifications. Complying with these standards not only guarantees product reliability but also affirms the manufacturer's commitment to quality and safety. Additionally, obtaining certifications from reputable third-party bodies further enhances confidence, offering assurance that the stainless steel wire mesh products meet stringent quality checks and performance benchmarks. Customers, especially from high-stakes industries, value these certifications as they significantly reduce the risks associated with component failure. In conclusion, understanding and specifying the right stainless steel wire mesh requires a balanced consideration of material grades, mesh count, wire diameter, weave type, and adherence to industry standards. By applying these criteria with expertise and authority, businesses can ensure that their selections meet the demands of their applications effectively, enhancing product performance while safeguarding operational integrity.

share:

Next:

Latest news

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

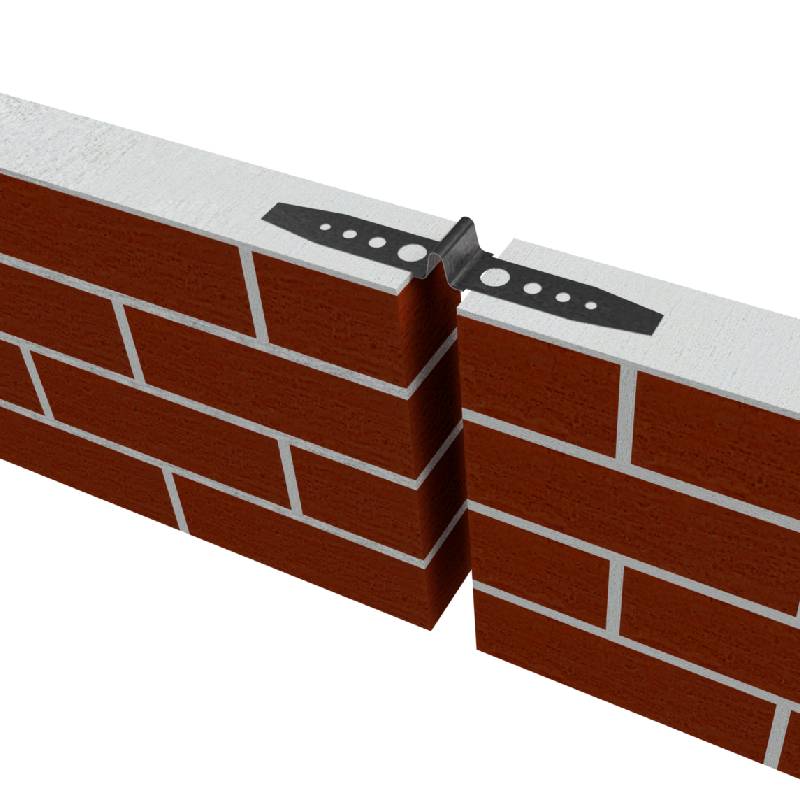

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025