- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

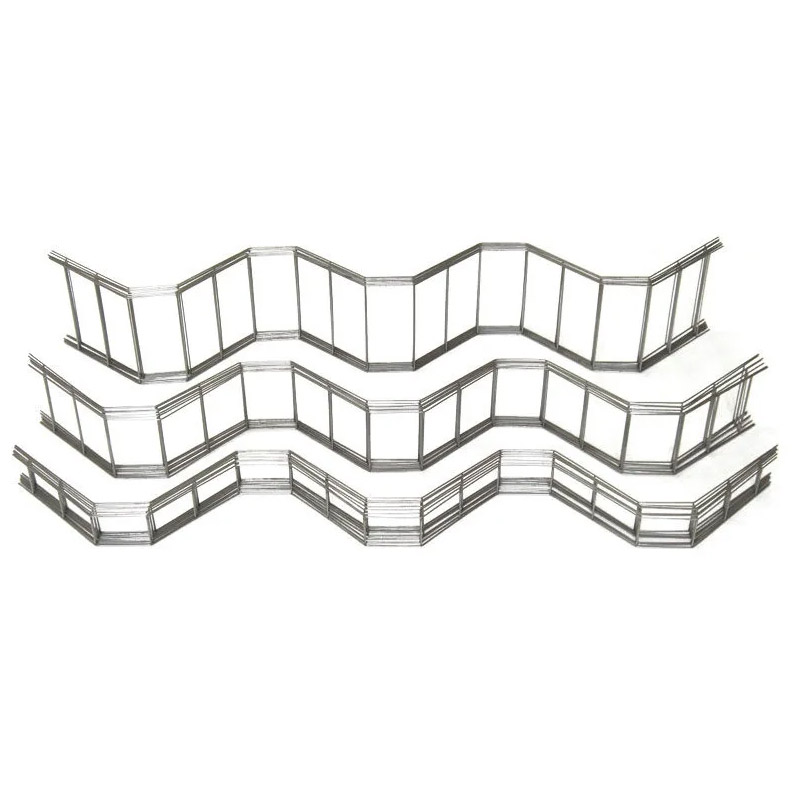

Concrete Wire Snake Spacer: Optimal Wire Separation & Cover

The Indispensable Role of Concrete Wire Snake Spacers in Modern Construction

In the intricate world of reinforced concrete construction, precision and structural integrity are paramount. Among the critical components ensuring the longevity and performance of concrete structures, the Concrete wire snake spacer stands out as an indispensable element. These innovative spacers are meticulously designed to maintain the precise distance between reinforcing steel (rebar) layers and the formwork, thereby guaranteeing the correct concrete cover. This critical function directly impacts the structural durability, fire resistance, and corrosion protection of the finished concrete element. Without accurate rebar placement, the structural capacity can be compromised, leading to premature deterioration, spalling, and costly repairs. This comprehensive guide delves into the technical aspects, application scenarios, and profound advantages of these vital construction aids.

Industry Trends and Market Dynamics

The global construction industry is experiencing dynamic shifts, driven by increasing demands for sustainable infrastructure, resilient buildings, and accelerated project timelines. This paradigm shift directly impacts the demand for high-performance construction materials and accessories, including advanced rebar spacers. Key trends influencing the market for Concrete wire snake spacer solutions include:

- Increased Focus on Durability and Longevity: With infrastructure projects designed for multi-decade lifespans, there's a heightened emphasis on materials that prevent early degradation, such as those that ensure optimal concrete cover for corrosion protection of rebar.

- Efficiency and Labor Optimization: Construction sites are constantly seeking ways to reduce labor costs and project durations. Spacers that are easy to install, provide stable support, and minimize rebar movement during concrete pouring contribute significantly to operational efficiency.

- Stringent Quality Standards: Regulatory bodies and project specifications are becoming more rigorous, demanding precise concrete cover as per standards like ACI 318, Eurocode 2, and BS 8500. This drives the adoption of reliable and uniformly produced spacers.

- Rise of Precast Concrete: The growing precast concrete market, known for its precision and off-site manufacturing, heavily relies on consistent rebar placement, making specialized spacers like the Concrete wire snake spacer essential for maintaining quality control during fabrication.

- Sustainable Construction Practices: While wire spacers are not inherently "green" in the same way as recycled plastic, their role in extending the service life of concrete structures reduces the need for premature repairs and replacements, thereby contributing to sustainability.

The market for rebar accessories is projected to grow steadily, driven by urbanization, population growth, and investments in both residential and commercial infrastructure. Specialized solutions like wire snake spacers, which offer superior stability and conformability to various rebar configurations, are poised for significant expansion within this evolving landscape.

Technical Specifications and Design Principles

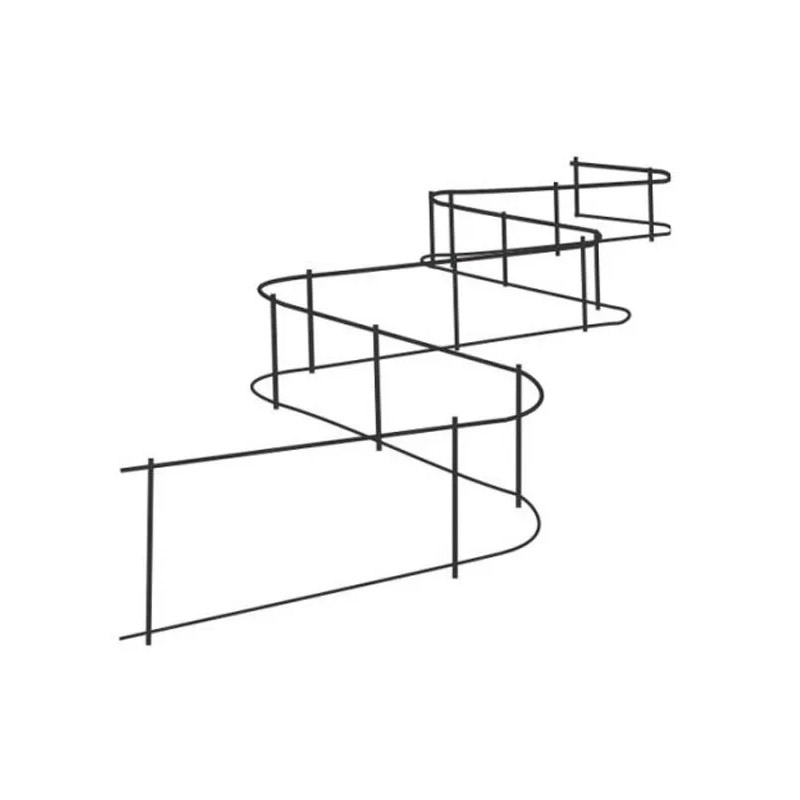

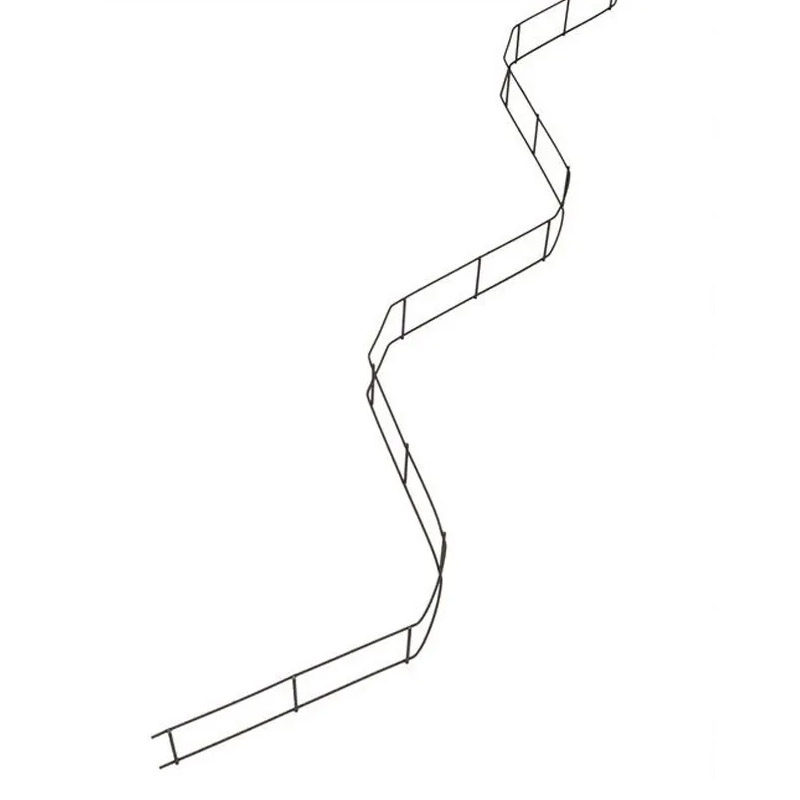

A Concrete wire snake spacer is characterized by its elongated, serpentine design, providing continuous support along the rebar length. This design mitigates localized stress points and ensures uniform cover. The core material is typically high-tensile steel wire, selected for its strength and minimal footprint within the concrete matrix.

Key Design Parameters:

- Wire Gauge: Ranging typically from 3mm to 6mm, determining the spacer's rigidity and load-bearing capacity. Thicker gauges are used for heavier rebar mats or greater cover heights.

- Cover Height: The critical dimension, dictating the distance between the rebar and the formwork. Standard heights range from 20mm to 100mm, or more for specialized applications, ensuring adequate concrete protection.

- Length: Typically supplied in lengths of 2 meters or customized as per project requirements, allowing for efficient placement across large areas.

- Leg Spacing/Pitch: The distance between the individual support points (legs) of the snake design, which influences stability and concrete flow. Optimized spacing prevents rebar sag while allowing concrete to fully encapsulate the rebar.

- Material Finish:

- Plain Steel: Suitable for internal, non-corrosive environments.

- Galvanized Steel: Offers enhanced corrosion resistance due to a zinc coating, ideal for humid or mildly corrosive conditions.

- Epoxy Coated Steel: Provides superior corrosion protection, essential for marine environments, chemical exposure, or critical infrastructure where durability is paramount. This coating also prevents rust staining on exposed concrete surfaces.

Product Specification Table: Concrete Wire Snake Spacer

| Parameter | Typical Range/Value | Relevant Standard/Note |

|---|---|---|

| Wire Diameter | 3.0 mm - 6.0 mm | Based on load and cover requirements |

| Concrete Cover Height | 20 mm - 100 mm (customizable) | Designed to ACI 318, Eurocode 2, BS 8500 |

| Standard Length | 2.0 meters (customizable) | Optimized for handling and placement |

| Material Grade | High-tensile steel wire (e.g., ASTM A82/A1064) | Ensures structural integrity and durability |

| Surface Finish Options | Plain, Galvanized (ASTM A641), Epoxy Coated (ASTM A775) | Corrosion protection for various environments |

| Load Bearing Capacity | Up to 200 kg/meter (depending on gauge and design) | Tested for deflection under load |

| Temperature Resistance | -40°C to +80°C | Maintains structural properties in varying climates |

Manufacturing Process of Concrete Wire Snake Spacers

The production of a high-quality Concrete wire snake spacer is a sophisticated industrial process involving precision engineering and stringent quality control. This ensures each spacer meets the demanding specifications required for critical structural applications. The typical manufacturing flow encompasses several key stages:

Process Flow:

- 1. Material Selection & Procurement: High-grade steel wire rods are sourced, typically complying with international standards like ASTM A82/A1064 for plain wire or ASTM A641 for galvanized, ensuring optimal tensile strength and ductility. For epoxy-coated variants, specific pre-treatment capabilities are required.

- 2. Wire Drawing & Straightening: The steel wire rods are drawn through dies to achieve the precise diameter (gauge) required. This process also enhances tensile strength. Subsequently, the wire undergoes mechanical straightening to eliminate any curvature, ensuring dimensional accuracy for the subsequent forming stages.

- 3. Automated Bending & Forming: Specialized CNC wire-forming machines are employed to precisely bend the straightened wire into the characteristic "snake" or continuous support shape. These machines are programmed to achieve exact cover heights, leg spacing, and overall length, ensuring consistency across batches.

- 4. Resistance Welding: At critical intersections of the formed wire, such as where legs meet the main support bar, resistance welding is performed. This process uses high current to generate heat and fuse the wires together, creating robust and durable joints that can withstand significant loads during concrete pouring and curing.

-

5. Surface Treatment (if applicable):

- Hot-Dip Galvanization: For galvanized spacers, the formed and welded units are immersed in molten zinc. This creates a metallurgical bond, providing a sacrificial layer for superior corrosion protection as per ASTM A641.

- Epoxy Coating: For premium corrosion resistance, spacers undergo thorough cleaning, phosphating, and then are electrostatically sprayed with fusion-bonded epoxy powder, which is subsequently cured in an oven. This process adheres to standards like ASTM A775.

-

6. Quality Control & Testing: Throughout the process, rigorous quality checks are implemented. This includes:

- Dimensional Verification: Using calipers and gauges to confirm cover height, length, and wire diameter.

- Weld Integrity Testing: Destructive and non-destructive tests (e.g., pull tests) to ensure weld strength meets internal standards and potentially ISO 17659 (welding standards).

- Coating Thickness & Adhesion Testing: For galvanized and epoxy-coated products, measurements ensure uniform coating thickness and strong adhesion to the base metal, often adhering to ISO 2063 (thermal spraying) or ASTM D3359 (adhesion test).

- Load Bearing Capacity Tests: Spacers are tested under simulated load conditions to confirm they can support rebar weight without excessive deflection, crucial for maintaining concrete cover.

- 7. Packaging & Dispatch: Finished and inspected Concrete wire snake spacer units are bundled, often with protective wrapping, and packaged for safe transport to construction sites.

The meticulous attention to detail at each stage ensures that the final product not only meets but often exceeds industry standards, providing reliable support for critical concrete structures.

Precision manufacturing ensures the structural integrity of every Concrete wire snake spacer.

Application Scenarios and Usage Benefits

The versatility and robust design of the Concrete wire snake spacer make it suitable for a wide array of concrete construction applications, particularly where maintaining a consistent concrete cover over large areas is crucial. Its continuous support prevents rebar sag, a common issue that can compromise structural performance.

Typical Application Scenarios:

- Large Slab-on-Grade Foundations: Ideal for industrial floors, warehouse slabs, and commercial building foundations where extensive rebar mats require continuous and stable support across vast areas.

- Bridge Decks and Infrastructure: In critical infrastructure projects, precise concrete cover is non-negotiable for ensuring long-term durability against environmental factors and heavy loads. Concrete wire snake spacer units provide reliable support for complex rebar configurations.

- Parking Structures: Multi-story parking garages benefit from the uniform cover provided, which helps prevent premature corrosion of rebar due to de-icing salts and vehicular fluids.

- Precast Concrete Elements: In a factory setting, consistency is key. These spacers facilitate accurate rebar placement during the casting of beams, columns, wall panels, and hollow-core slabs, leading to high-quality, repeatable components.

- Retaining Walls and Water Retaining Structures: Essential for maintaining cover in structures exposed to moisture, preventing water ingress and subsequent rebar corrosion.

- Basement Slabs and Raft Foundations: Ensures uniform cover in subterranean structures where moisture exposure can be significant, extending the service life of the foundation.

Demonstrated Advantages in Use:

- Superior Load Distribution: Unlike individual chairs, the continuous "snake" design distributes the rebar load more effectively, minimizing local deformation and ensuring the entire rebar cage remains at the specified height.

- Enhanced Corrosion Resistance: Especially with galvanized or epoxy-coated variants, these spacers contribute directly to the longevity of the structure by ensuring the rebar maintains adequate concrete cover, which is the primary defense against corrosive agents like chlorides and carbonation.

- Optimized Concrete Flow: The open wire design minimizes obstruction to concrete flow during pouring, preventing honeycombing and ensuring full encapsulation of the rebar and the spacer itself, leading to a denser, more uniform concrete matrix.

- Reduced Installation Time: Their elongated form allows for rapid placement over large areas compared to individual chairs, significantly reducing labor hours for rebar setup.

- Prevents Punching Shear and Spalling: By ensuring uniform concrete cover, the risk of punching shear failure and surface spalling due to exposed or inadequately covered rebar is drastically reduced, enhancing safety and aesthetic appeal.

- Cost-Effectiveness over Service Life: While the initial cost might be slightly higher than basic plastic spacers, the long-term benefits in terms of structural integrity, reduced maintenance, and extended service life translate into significant cost savings over the project's lifecycle.

These multifaceted advantages underscore why Concrete wire snake spacer solutions are increasingly the preferred choice for engineers and contractors prioritizing structural excellence and long-term performance.

Technical Advantages and Performance Metrics

The superior design and robust construction of the Concrete wire snake spacer translate into several distinct technical advantages that set it apart from other rebar spacing solutions. These advantages are crucial for meeting the stringent performance requirements of modern construction.

Key Technical Advantages:

- Exceptional Stability and Rigidity: Constructed from high-tensile steel wire, these spacers offer superior rigidity. Their continuous support structure effectively prevents rebar movement, bowing, or sagging during the concrete pouring process, even under dynamic conditions.

- Minimal Surface Contact Area: The wire design ensures minimal contact points with the formwork. This is particularly advantageous for exposed concrete surfaces where aesthetics are important, as it significantly reduces the likelihood of "show-through" marks or rust stains when using coated variants.

- High Compressive Strength: Engineered to withstand significant vertical loads from rebar, foot traffic, and the weight of wet concrete, they maintain their form and specified cover height without crushing or deforming.

- Thermal Compatibility with Concrete: Steel has a coefficient of thermal expansion similar to that of concrete. This compatibility minimizes internal stresses due to temperature fluctuations, reducing the risk of cracking around the spacer and ensuring long-term bond integrity.

- Durability in Harsh Environments: Galvanized and epoxy-coated versions offer excellent resistance to aggressive chemicals, chlorides, and moisture, making them suitable for marine environments, wastewater treatment plants, and industrial facilities where corrosion is a major concern.

- Fire Resistance: Unlike plastic spacers which can melt or deform at high temperatures, steel wire spacers maintain their structural integrity during a fire, contributing to the overall fire resistance rating of the concrete element by ensuring rebar remains in its protective cover.

The robust design of Concrete wire snake spacer ensures precise rebar positioning and optimal concrete cover.

Performance Metrics:

Performance of Concrete wire snake spacer is often evaluated against several key metrics:

- Deflection Under Load: Measured to ensure the spacer maintains its specified height under maximum expected rebar and concrete weight. High-quality spacers exhibit minimal deflection, typically less than 2-3mm under significant load.

- Bond Strength: The interaction between the steel wire and concrete is critical. The design ensures proper encapsulation by concrete, promoting excellent bond strength and preventing internal voids.

- Corrosion Resistance (for coated types): Tested via salt spray chambers (ASTM B117) or electrochemical impedance spectroscopy to quantify the effectiveness of galvanization or epoxy coatings in inhibiting rust over extended periods.

- Durability in Freeze-Thaw Cycles: For external applications, spacers are tested for their ability to withstand repeated freezing and thawing without material degradation or loss of structural integrity.

Vendor Comparison: Concrete Wire Snake Spacers vs. Alternatives

The choice of rebar spacer profoundly impacts project efficiency, structural integrity, and long-term costs. While various types of spacers are available, understanding the comparative advantages of the Concrete wire snake spacer against common alternatives is essential for informed decision-making in B2B procurement.

Product Comparison Table: Rebar Spacers

| Feature | Concrete Wire Snake Spacer | Individual Plastic Chairs | Concrete Block Spacers |

|---|---|---|---|

| Material | High-tensile steel wire (plain, galvanized, epoxy-coated) | Recycled or virgin plastic (e.g., Polypropylene) | Precast concrete, often fiber-reinforced |

| Rebar Support | Continuous, line-contact support for rebar mats | Point-contact support, typically one per bar intersection | Area-contact support, individual blocks placed |

| Load Bearing | Excellent; distributes load efficiently, minimal deflection | Good for light loads; risk of crushing/deformation under heavy loads | Excellent; very high compressive strength |

| Installation Speed | Fast for large areas due to elongated form | Slower for large areas, requires more units and individual placement | Moderate; heavier, requires more careful placement |

| Concrete Flow | Minimal obstruction; excellent for concrete encapsulation | Can create minor voids if design is not open enough | Can create significant voids/cold joints if not properly placed and vibrated |

| Corrosion Resistance (in concrete) | Excellent (especially galvanized/epoxy-coated) | Excellent (plastic is inert) | Excellent (same material as concrete, if properly mixed) |

| Formwork Markings | Minimal (small contact points); negligible with coated types | Can leave distinct marks on exposed concrete | Minimal, blends well with concrete surface |

| Cost (Unit/Linear) | Moderate to high (initial), high value over lifetime | Low (initial), can be higher if many units are needed | Moderate (initial) |

| Suitability | High-rise, industrial slabs, infrastructure, precast; critical applications | Light residential, non-structural elements, vertical rebar (clip-on types) | Heavy civil, thick slabs, where blending with concrete is crucial |

While individual plastic chairs offer a cost-effective solution for less demanding applications, and concrete blocks excel in very heavy-duty scenarios, the Concrete wire snake spacer strikes an optimal balance of stability, ease of installation, and long-term performance for a broad range of critical concrete structures. Its continuous support and robust material make it a superior choice for ensuring accurate cover and structural longevity, especially in projects where quality and durability cannot be compromised.

Customized Solutions and Project-Specific Offerings

Recognizing that no two construction projects are identical, leading manufacturers of Concrete wire snake spacer solutions offer extensive customization capabilities. This flexibility ensures that the spacers perfectly align with specific design requirements, structural loads, and environmental conditions of a particular project.

Areas of Customization:

- Variable Cover Heights: Beyond standard dimensions, manufacturers can produce spacers for highly specific concrete cover requirements, crucial for specialized architectural concrete or structures exposed to extreme environmental conditions.

- Wire Gauge and Material Strength: The wire diameter can be adjusted to match varying rebar weights or to achieve higher load-bearing capacities for heavily reinforced slabs or bridge decks.

- Length Modifications: While 2-meter lengths are standard, custom lengths can optimize installation efficiency for unique formwork dimensions, minimizing cuts and waste on-site.

- Specialized Coatings: In addition to standard galvanization or epoxy, specific coating types can be applied for unique chemical resistance needs or aesthetic considerations.

- Design Modifications: For complex rebar geometries or multi-layer reinforcement, the "snake" pattern itself can be adapted to provide optimal support and concrete flow without compromising structural integrity.

- Material Traceability: For critical projects, manufacturers can provide detailed material certifications and traceability documentation, ensuring full compliance with project specifications and regulatory standards.

Collaborating with experienced technical teams from the supplier can facilitate the design and production of tailor-made Concrete wire snake spacer solutions, ensuring optimal performance and cost-effectiveness for even the most challenging construction endeavors.

Real-World Application Case Studies

The practical benefits of the Concrete wire snake spacer are best illustrated through its application in diverse, high-stakes construction projects where precision, durability, and efficiency were paramount.

Case Study 1: High-Rise Commercial Tower Foundation

Project: "Metropolis Tower" – a 60-story mixed-use commercial and residential building in a major urban center.

- Challenge: Constructing a raft foundation with multiple layers of heavy rebar (up to 40mm diameter) over an area of 5,000 sq meters. The project demanded extremely precise concrete cover (75mm bottom cover) to ensure structural integrity and a 100-year design life. Traditional point-support chairs were prone to crushing under the rebar weight and extensive foot traffic during installation.

- Solution: The contractor opted for 5mm gauge, galvanized Concrete wire snake spacer units, custom-fabricated to 75mm cover height and supplied in 2.5-meter lengths.

- Outcome: The continuous support provided by the snake spacers maintained the rebar elevation uniformly across the entire foundation. Installation time for spacer placement was reduced by an estimated 20% compared to using individual chairs. Post-pour inspections confirmed consistent concrete cover, contributing significantly to the foundation's expected durability. The galvanization provided an added layer of protection against potential moisture ingress from the surrounding soil.

Case Study 2: Coastal Bridge Deck Rehabilitation

Project: Rehabilitation of a 2km long concrete bridge deck exposed to a harsh marine environment with high chloride attack risk.

- Challenge: Achieving a highly uniform 50mm concrete cover for new epoxy-coated rebar to prevent chloride-induced corrosion, which was the primary cause of original deck deterioration. The deck's curvature also posed challenges for rigid spacing solutions.

- Solution: Epoxy-coated Concrete wire snake spacer units (4mm gauge, 50mm cover) were specified. Their flexible yet robust design allowed them to conform slightly to the deck's minor curvatures while providing continuous support. The epoxy coating on the spacers matched the rebar, ensuring no dissimilar material interaction or potential rust points.

- Outcome: The epoxy-coated wire snake spacers provided an inert, corrosion-resistant interface within the concrete, crucial for the aggressive coastal environment. The continuous support significantly improved the consistency of the rebar mat, leading to an optimal concrete cover. The project's post-completion report highlighted the spacers as a key factor in achieving the required durability and service life extension for the bridge.

Customer Feedback & Experience:

"For our industrial slab projects, the stability of the rebar mat is critical. The Concrete wire snake spacer has consistently delivered on this. We've seen a noticeable reduction in rebar sag and movement during pours, which directly translates to fewer quality control issues and a more robust final product. The installation speed is also a major advantage, especially on large, repetitive areas." – Project Manager, Industrial Concrete Contractor.

Ensuring consistent cover for rebar with Concrete wire snake spacers in a real-world application.

Quality Assurance, Certifications, and Trustworthiness

Trust in B2B supply chains is built on consistent quality, adherence to standards, and reliable support. For specialized components like the Concrete wire snake spacer, demonstrating adherence to robust quality assurance protocols and offering comprehensive customer support is paramount.

Commitment to Quality & Certifications:

- ISO 9001:2015 Certification: Adherence to an internationally recognized Quality Management System ensures consistent product quality, from raw material sourcing to final dispatch. This includes documented procedures for design, production, inspection, and customer service.

- Material Compliance: All steel wire used complies with relevant ASTM or equivalent international standards (e.g., ASTM A82 for plain wire, ASTM A641 for galvanized, ASTM A775 for epoxy-coated), guaranteeing specified tensile strength and material composition.

- Regular Internal & Third-Party Audits: Manufacturing facilities undergo regular internal and independent third-party audits to verify compliance with quality standards and production specifications.

- Test Reports: Comprehensive test reports covering dimensional accuracy, weld strength, load-bearing capacity, and coating performance (where applicable) are available upon request for each batch.

FAQ Module:

- Q: What is the recommended spacing for Concrete wire snake spacers?

- A: The ideal spacing depends on the rebar diameter, weight, and desired stiffness. Generally, spacers are placed at intervals of 0.8 to 1.5 meters along the rebar to prevent sag. For heavier rebar mats, closer spacing is recommended.

- Q: Can these spacers be used with all types of formwork?

- A: Yes, Concrete wire snake spacer units are compatible with most formwork types, including timber, steel, and plastic. Their minimal contact points reduce the risk of damage or marking to the formwork surface, especially beneficial for architectural concrete.

- Q: How do these spacers handle different rebar sizes?

- A: The open design of wire snake spacers accommodates a range of rebar diameters by resting them on the continuous top bar. The critical factor is selecting the correct spacer height for the desired concrete cover, irrespective of minor variations in rebar size.

- Q: Are epoxy-coated wire spacers necessary for all projects?

- A: Epoxy-coated spacers are highly recommended for structures in aggressive environments (e.g., marine, chemical plants, bridge decks exposed to de-icing salts) where superior corrosion protection is critical for long-term durability. For internal or less corrosive environments, galvanized or plain wire spacers may suffice.

Lead Time & Fulfillment Details:

- Standard Products: Typical lead times for standard Concrete wire snake spacer configurations are 2-4 weeks, depending on order volume and current production schedules.

- Customized Orders: Lead times for custom solutions will be quoted individually, typically requiring an additional 1-2 weeks for design and tooling adjustments.

- Logistics & Shipping: We partner with reputable logistics providers to ensure timely and secure delivery worldwide. Expedited shipping options are available upon request for urgent project timelines.

Warranty Commitments:

Our Concrete wire snake spacer products come with a standard 1-year warranty against manufacturing defects in material and workmanship, provided they are stored, handled, and installed according to recommended guidelines and industry best practices. Extended warranties for specific project requirements can be negotiated.

Customer Support & After-Sales Service:

We are committed to providing exceptional customer support. Our dedicated technical team is available to assist with product selection, application advice, custom design consultations, and problem resolution. We offer:

- Direct access to product specialists and engineers.

- Prompt response to inquiries and technical queries.

- Assistance with order tracking and logistics.

- Post-delivery support and feedback mechanisms.

Conclusion

The Concrete wire snake spacer is far more than a simple accessory; it is a fundamental component in achieving precision and longevity in reinforced concrete structures. Its robust design, superior load distribution, and material versatility make it an invaluable asset for engineers and contractors aiming for optimal concrete cover, enhanced structural integrity, and reduced long-term maintenance costs. As the construction industry continues to push the boundaries of design and durability, the role of high-quality, reliable spacing solutions like the wire snake spacer will only grow in importance, underpinning the safety and resilience of our built environment.

References

- American Concrete Institute (ACI). "Building Code Requirements for Structural Concrete (ACI 318) and Commentary."

- ASTM International. "Standard Specification for Steel Wire, Plain, for Concrete Reinforcement" (ASTM A82/A82M).

- ASTM International. "Standard Specification for Zinc-Coated (Galvanized) Steel Wire" (ASTM A641/A641M).

- ASTM International. "Standard Specification for Epoxy-Coated Steel Reinforcing Bars" (ASTM A775/A775M).

- Eurocode 2: Design of concrete structures – Part 1-1: General rules and rules for buildings. European Committee for Standardization.

- British Standards Institution. "BS 8500: Concrete – Complementary British Standard to BS EN 206."

- International Organization for Standardization (ISO). "Quality management systems – Requirements" (ISO 9001:2015).

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025